Zooplankton waste separator

A zooplankton and waste technology, which is applied in the fields of biomass pretreatment, bioreactor/fermenter combination, bioreactor/fermenter for specific purposes, etc., which can solve the problems of low efficiency, large error, zooplankton damage, etc. To achieve the effect of convenient cleaning and improve efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

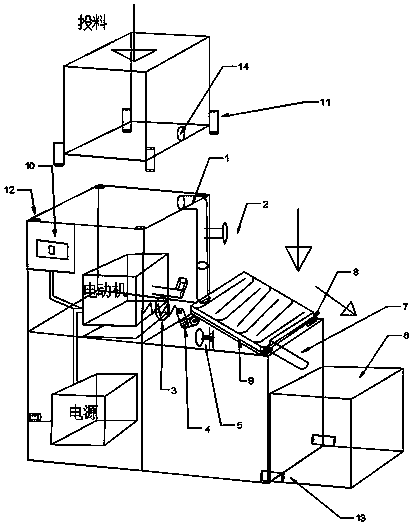

[0028] exist figure 1 In the shown embodiment, it can be seen that the present invention adopts a detachable design to facilitate disassembly and cleaning. Viewed from the front, the overall main shape of the present invention is five cuboids, one of which is a feeding box (15). The feeding box (15) is designed with a bottom and a total of five sides around it. There is no upper surface, and it is used for feeding. The position distribution On the top, insert the sleeve feed pipe (1) outside. Below the feeding box (15) is motor and control part box, and the inside is designed with control panel (10), motor and vibrating device, damping plate etc. Below the motor and control part box is a power supply box, which is designed with a rechargeable storage battery, a circuit board, and an external AC plug. On the right side of the power box is the bracket box, which is used to support the filter plate on it. The filter plate is distributed with filter grooves with bends and turns...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com