Preparation method of water-resistant and high-strength PVC wood-plastic composite

A wood-plastic composite material, high-strength technology, applied in the field of composite material processing, can solve the problems of plastic unfavorable environment protection, water resistance, poor corrosion resistance, plastic is not easy to degrade, etc., to improve comprehensive use quality, optimize strength, The effect of enhanced adsorption capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

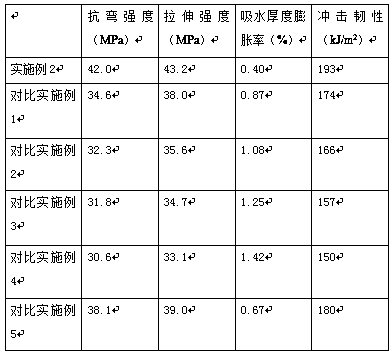

Examples

Embodiment 1

[0035] A preparation method of water-resistant high-strength PVC wood-plastic composite material, comprising the steps of:

[0036] (1) Preparation of functional additives:

[0037] 1) Put the montmorillonite in the hydrochloric acid solution for 4 minutes and then take it out, then put it in the sodium hydroxide solution for 5 minutes and take it out, and finally wash it with deionized water until it is neutral and set it aside;

[0038] 2) Put the montmorillonite treated in operation 1) into the calcination furnace for calcination treatment, and take it out after 1.5h for later use;

[0039] 3) Put the montmorillonite treated in operation 2) into the microwave irradiation box for irradiation treatment, and take it out after 40 minutes for later use;

[0040] 4) 12-hydroxystearic acid, manganese sulfate, zinc sulfate, sodium pyrophosphate, lanthanum nitrate, cerium nitrate, montmorillonite, xylene, ethyl acetate, and deionized water after operation 3) are treated according t...

Embodiment 2

[0060] A preparation method of water-resistant high-strength PVC wood-plastic composite material, comprising the steps of:

[0061] (1) Preparation of functional additives:

[0062] 1) Put the montmorillonite into the hydrochloric acid solution for 5 minutes and then take it out, then put it into the sodium hydroxide solution for 7 minutes and then take it out, and finally rinse it with deionized water until it is neutral and set it aside;

[0063] 2) Put the montmorillonite treated in operation 1) into the calcination furnace for calcination treatment, and take it out after 2 hours for later use;

[0064] 3) Put the montmorillonite treated in operation 2) into the microwave irradiation box for irradiation treatment, and take it out after 43 minutes for later use;

[0065] 4) 12-hydroxystearic acid, manganese sulfate, zinc sulfate, sodium pyrophosphate, lanthanum nitrate, cerium nitrate, montmorillonite, xylene, ethyl acetate, and deionized water after operation 3) are treate...

Embodiment 3

[0085] A preparation method of water-resistant high-strength PVC wood-plastic composite material, comprising the steps of:

[0086] (1) Preparation of functional additives:

[0087] 1) First put the montmorillonite into the hydrochloric acid solution for 6 minutes and then take it out, then put it into the sodium hydroxide solution for 8 minutes and then take it out, and finally rinse it with deionized water until it is neutral and set it aside;

[0088] 2) Put the montmorillonite treated in operation 1) into the calcination furnace for calcination treatment, and take it out after 2.5 hours for later use;

[0089] 3) Put the montmorillonite treated in operation 2) into the microwave irradiation box for irradiation treatment, and take it out after 45 minutes for later use;

[0090] 4) 12-hydroxystearic acid, manganese sulfate, zinc sulfate, sodium pyrophosphate, lanthanum nitrate, cerium nitrate, montmorillonite, xylene, ethyl acetate, and deionized water after operation 3) ar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com