Antifreezing and high temperature-resistant hydrophobic insulation board

A thermal insulation board, high temperature resistant technology, applied in thermal insulation, building components, applications, etc., can solve the problems of application limitations, low mechanical strength, low thermal conductivity, etc., to improve indoor environment, good processing performance, low thermal conductivity. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0070] This embodiment relates to a kind of antifreeze and high temperature resistant hydrophobic insulation board, such as figure 1 As shown, it consists of an outer layer 1, an inner layer 2, and an outer layer 1 arranged in sequence;

[0071] The outer layer 1 consists of the following raw materials in parts by weight:

[0072] 42 parts of pozzolan Portland cement;

[0073] 10 parts of soapstone powder;

[0074] 8 parts of Xinjiang Qiganbulak vermiculite tailings;

[0075] 3 parts of bismuth vanate;

[0076] Dispersant FT-78 0.8 parts;

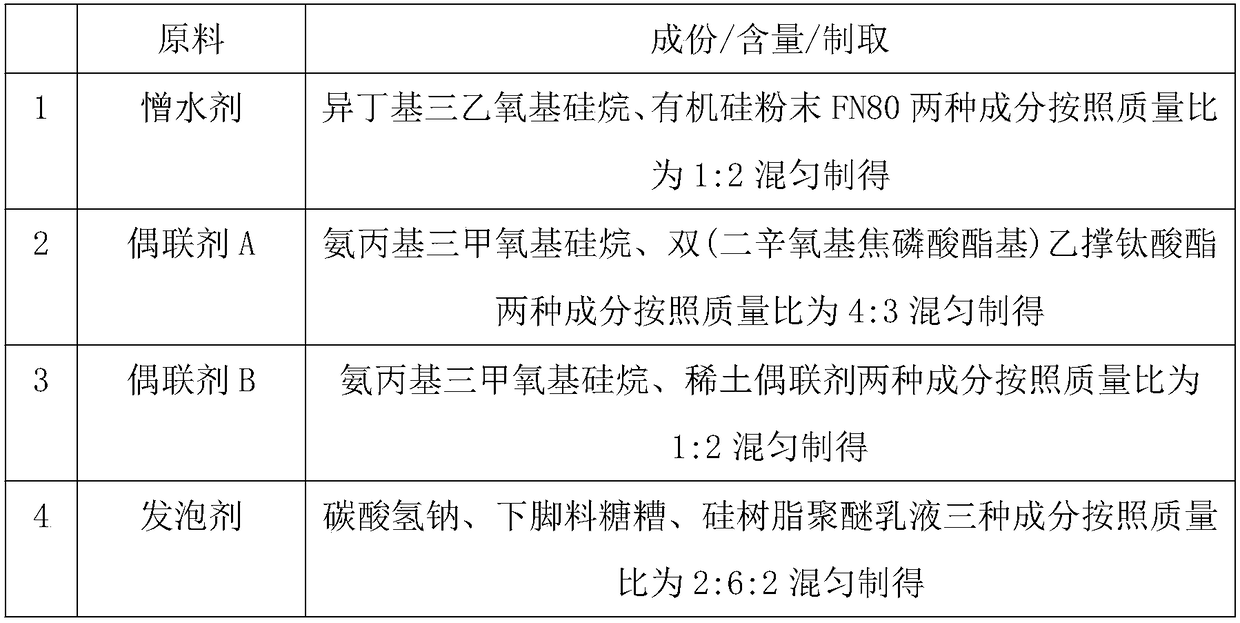

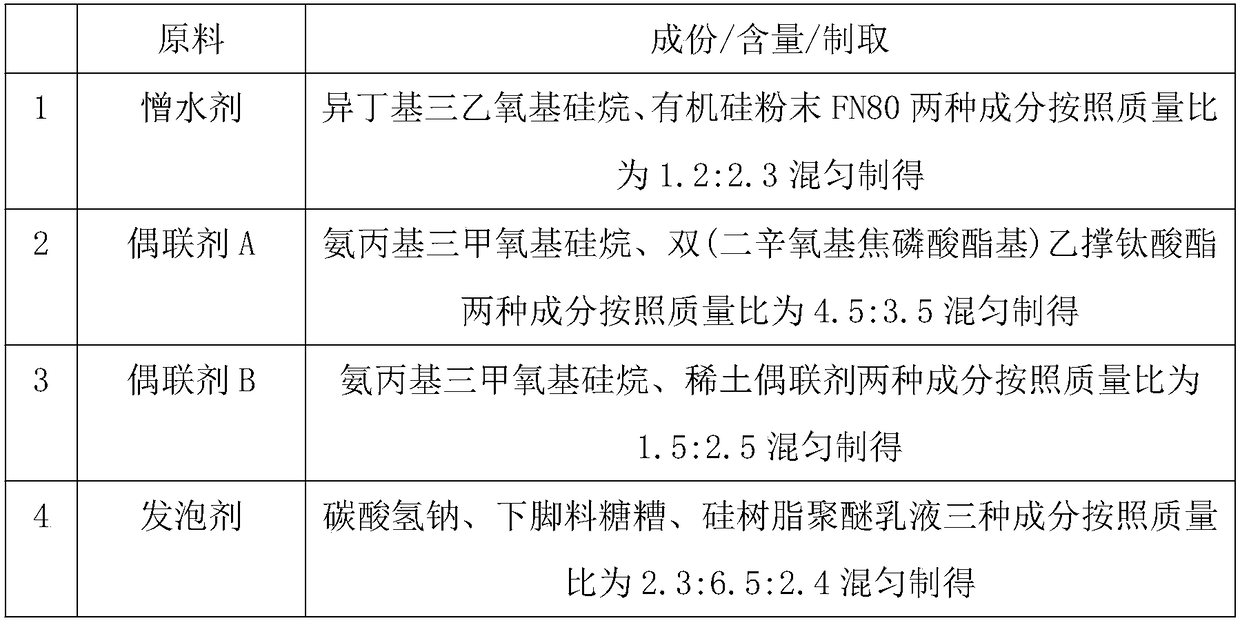

[0077] 0.6 parts of water repellent;

[0078] 1.5 parts of coupling agent B;

[0079] The inner layer 2 consists of the following raw materials in parts by weight:

[0080] Sea pumice powder 38 parts;

[0081] 25 parts of rectorite powder;

[0082] 2 parts of aluminum sulfate;

[0083] 6 parts mallow stem bark fiber;

[0084] Three-dimensional latex powder swf04 7 parts;

[0085] 3 parts coumarone resin;

[0086] 1 part foaming...

Embodiment 2

[0098] This embodiment relates to a kind of antifreeze and high temperature resistant hydrophobic insulation board, such as figure 1 As shown, it consists of an outer layer 1, an inner layer 2, and an outer layer 1 arranged in sequence;

[0099] The outer layer 1 consists of the following raw materials in parts by weight:

[0100] 46 parts of pozzolan Portland cement;

[0101] 12 parts of soapstone powder;

[0102] 8.5 parts of vermiculite tailings from Xinjiang Qiganbulake;

[0103] 3.5 parts of bismuth vanate;

[0104] Dispersant FT-78 0.9 parts;

[0105] 0.7 parts of water repellent;

[0106] 1.9 parts of coupling agent B;

[0107] The inner layer 2 consists of the following raw materials in parts by weight:

[0108] Sea pumice powder 41 parts;

[0109] 28 parts of rectorite powder;

[0110] 2.5 parts of aluminum sulfate;

[0111] 6.5 parts of mallow stem bark fiber;

[0112] Three-dimensional latex powder swf04 8 parts;

[0113] 3.5 parts of coumarone resin;

...

Embodiment 3

[0126] This embodiment relates to a kind of antifreeze and high temperature resistant hydrophobic insulation board, such as figure 1 As shown, it consists of an outer layer 1, an inner layer 2, and an outer layer 1 arranged in sequence;

[0127] The outer layer 1 consists of the following raw materials in parts by weight:

[0128] 49 parts of pozzolan Portland cement;

[0129] 13 parts of soapstone powder;

[0130] 9 parts of Xinjiang Qiganbulake vermiculite tailings;

[0131] 4 parts of bismuth vanate;

[0132] Dispersant FT-78 1 part;

[0133] 0.8 parts of water repellent;

[0134] 2.1 parts of coupling agent B;

[0135] The inner layer 2 consists of the following raw materials in parts by weight:

[0136] Sea pumice powder 42 parts;

[0137] 30 parts of rectorite powder;

[0138] 2.7 parts of aluminum sulfate;

[0139] 7 parts of mallow stem bark fiber;

[0140] Three-dimensional latex powder swf04 9 parts;

[0141] 4 parts coumarone resin;

[0142] 1.5 parts o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com