A method for controlling organic fouling of reverse osmosis membrane

A technology of reverse osmosis membrane and control method, which is applied in the direction of semipermeable membrane separation, water treatment parameter control, chemical instruments and methods, etc., and can solve the problems of lack of research on component removal and no combination use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0046] The preparation and storage methods of clean activated carbon are as follows: use coconut shell granular activated carbon with a particle size of 1-2mm. Clean activated carbon was prepared; the cleaned activated carbon was dried in an oven at 70°C, and then placed in a beaker and sealed away from light.

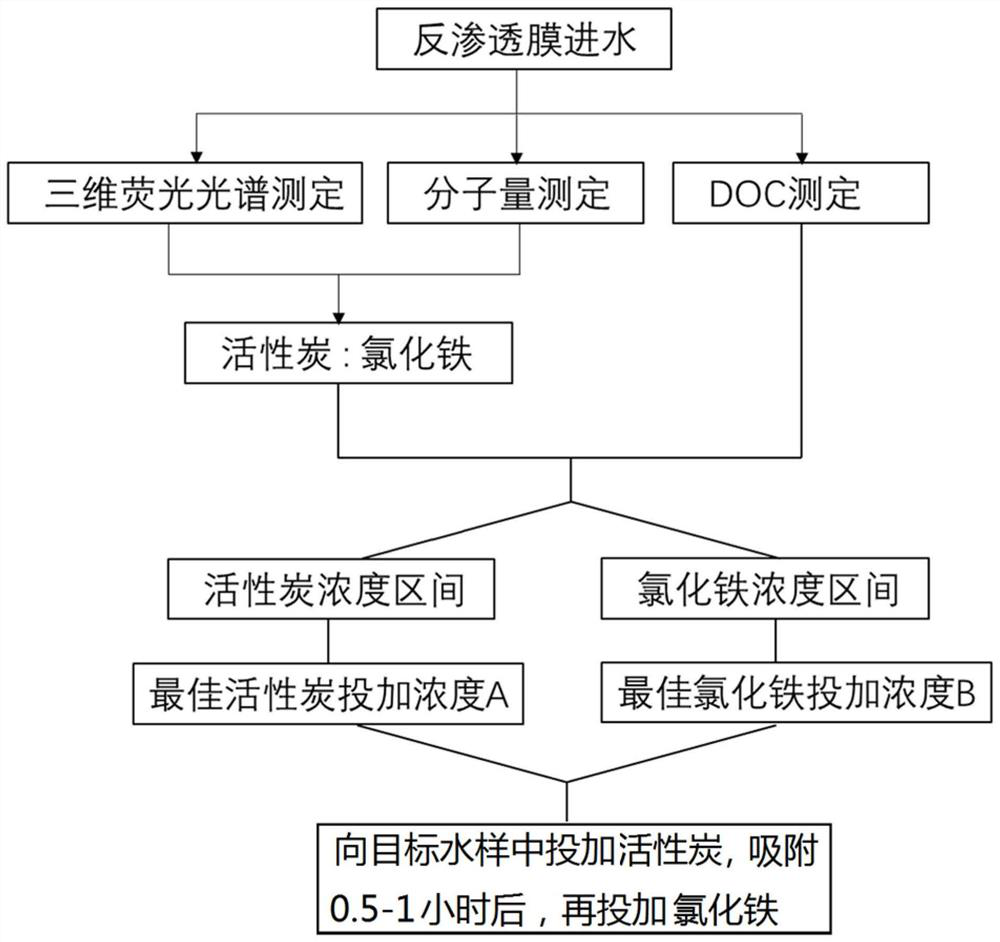

[0047] The present invention firstly determines the dosing ratio of activated carbon and ferric chloride by measuring the molecular weight of organic matter in the water sample and the measurement results of the three-dimensional fluorescence spectrum; determines the dosing concentration range of activated carbon and ferric chloride according to the concentration of DOC, and respectively The corresponding DOC removal rate is obtained, and the optimal activated carbon dosage A and the optimal ferric chloride dosage B are determined by the minimum dosage value required for stable removal of DOC, and activated carbon is added to the reverse osmosis influent to make it The...

Embodiment 1

[0051] In this embodiment, the target feedwater 1 is adopted, and the determination of the organic fouling control method in the reverse osmosis membrane feedwater 1 is as follows:

[0052] (1) prepare two kinds of water treatment agents of ferric chloride stock solution and clean gac;

[0053] (2) Determine the optimal dosage concentration A of activated carbon and the optimal dosage concentration B of ferric chloride:

[0054] (21) Take out the influent water sample 1 from the target influent water 1 of the reverse osmosis membrane, and use a liquid chromatograph to measure the molecular weight of the organic matter in the reverse osmosis influent water sample 1, and its molecular weight distribution diagram is as follows figure 2 As shown, use a fluorescence spectrophotometer to measure and obtain the three-dimensional fluorescence spectrum of the reverse osmosis membrane influent water sample 1, as shown in image 3 shown by figure 2 It can be seen that the influent wa...

Embodiment 2

[0072] In this embodiment, the target influent 2 is selected, and its organic fouling control method is the same as that in Embodiment 1, the difference is that:

[0073](ⅰ) Molecular weight distribution of organic matter in influent water sample 2 is as follows Figure 5 As shown, its three-dimensional fluorescence spectrum is shown in Figure 6 shown by Figure 5 It can be seen that the influent water sample 2 is at 10 3 -10 4 Water samples with obvious absorption peaks in the Da range, and in 10 2 -10 3 For water samples without obvious absorption peaks in the Da range, the Figure 6 It can be seen that the influent water sample 2 has obvious fluorescence response in the IV area and the VI area, thus, it is determined that the optimal concentration ratio of activated carbon and ferric chloride in the influent water sample 2 is 2:1;

[0074] (ii) Take 5ml of the water sample to be tested, pass through a 0.45μm filter membrane, and measure the DOC concentration of the i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com