Glass sheet feeding mechanism

A glass sheet and sliding rod technology, which is applied to conveyor objects, furnaces, lighting and heating equipment, etc., can solve the problems of scratches and cracks on the glass surface, and achieve the effect of eliminating adhesion and ingenious structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The above solution will be further described below in conjunction with specific embodiments. It should be understood that these examples are used to illustrate the present application and not limit the scope of the present application. The implementation conditions used in the examples can be further adjusted according to the conditions of specific manufacturers, and the implementation conditions not indicated are usually the conditions in routine experiments.

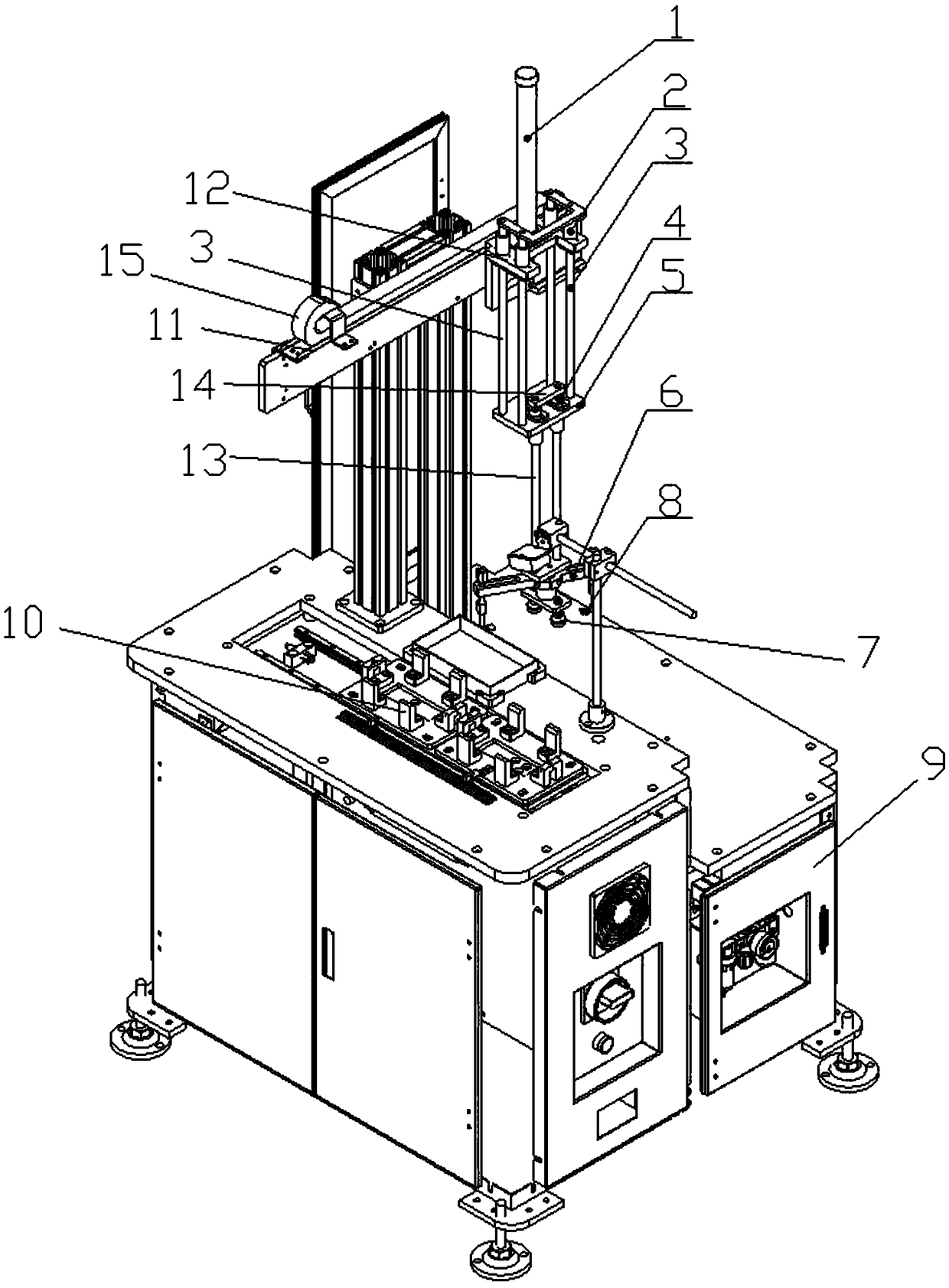

[0031] figure 1 A specific embodiment of the glass sheet feeding mechanism of the present application is shown, which includes a base frame 9, on which are arranged: a glass sheet positioning and placing table 10, a horizontal guide rail 11, a slide seat 12, a cylinder 1, a lift Seat 5, slide bar 13 and sucker 7. in:

[0032] The glass sheet positioning platform 10 is used to place the glass sheets to be grasped and stacked together.

[0033] The horizontal guide rail 11 is fixed on the base frame 9 and is l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com