Method for controlling oil film thickness of static pressure workbench based on working condition coefficient method

A technology of oil film thickness and working condition coefficient, used in manufacturing tools, metal processing equipment, metal processing machinery parts, etc., can solve the problem of difficult to achieve precise control of oil film thickness, and achieve accurate adjustment results, simple control process, and small adjustment errors. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

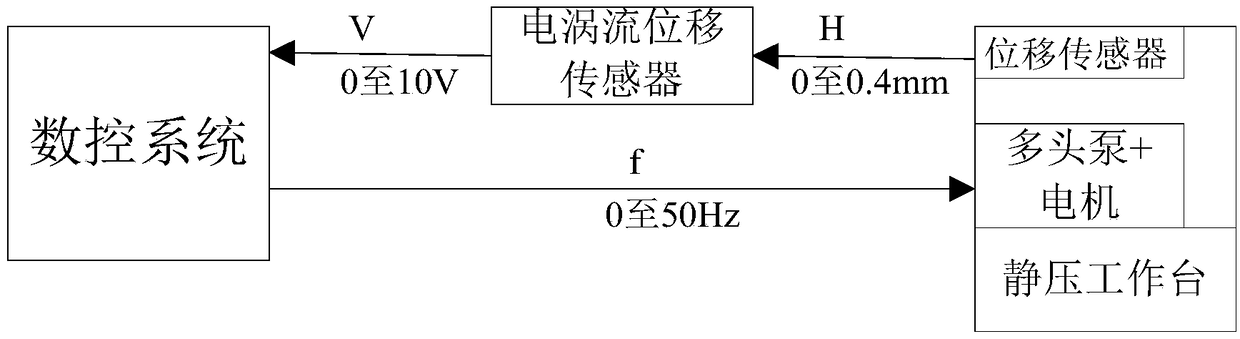

Image

Examples

specific Embodiment

[0049] The test was carried out on a Φ2500mm static pressure rotary workbench in a certain factory. The hydraulic system of the workbench has constant temperature conditions, set at 27 degrees, the maximum bearing capacity of the workbench is 40T, and the self-weight of the workbench is 5T. Three load blocks of about 10T are used for the test, the purpose is to verify the correctness of the oil film thickness control model under different load conditions.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com