Beater bar

The technology of a slat and impact crusher is applied in the field of batter, which can solve the problems of low utilization rate, unused, unfavorable, etc., and achieve the effect of high utilization rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

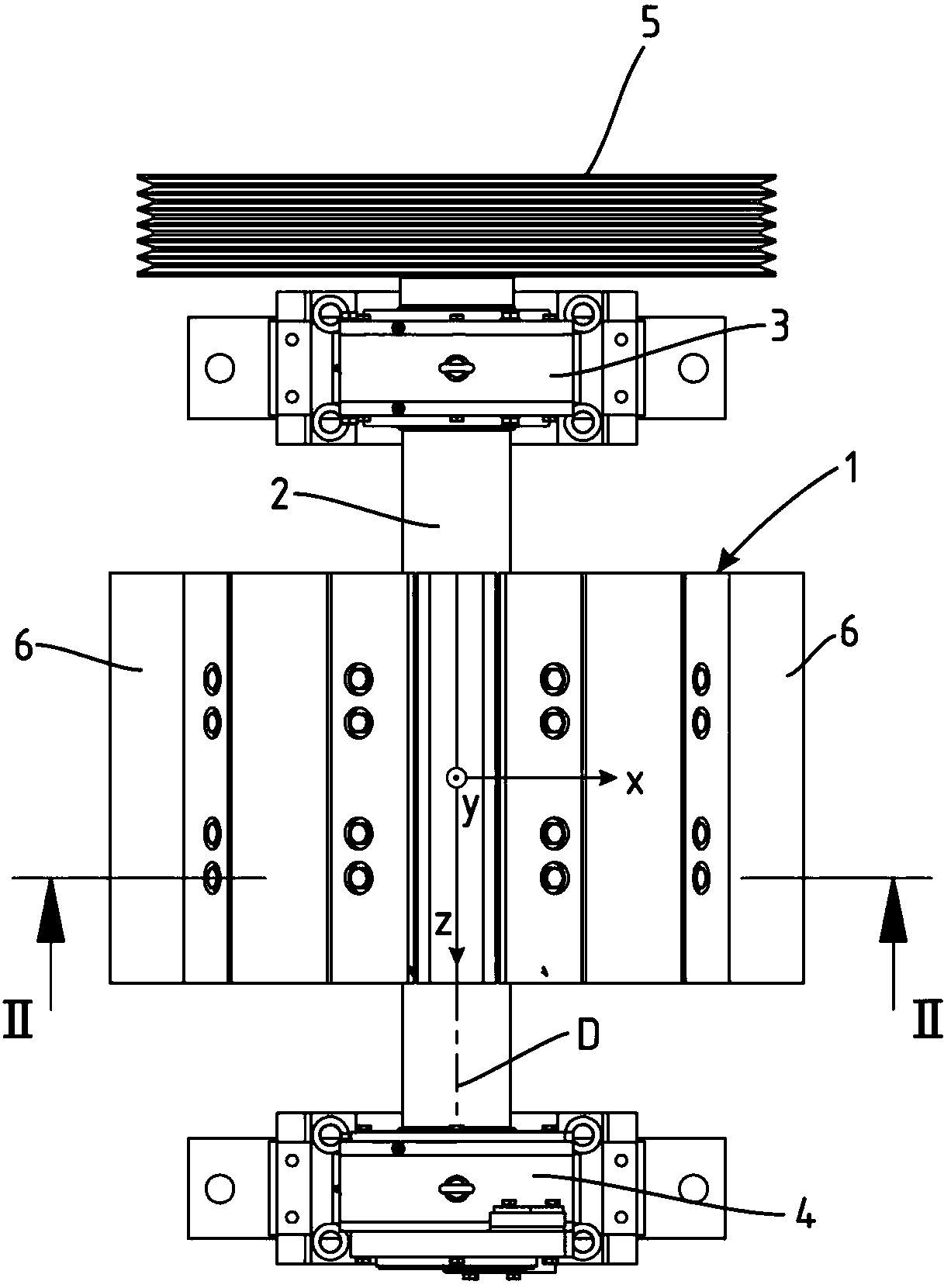

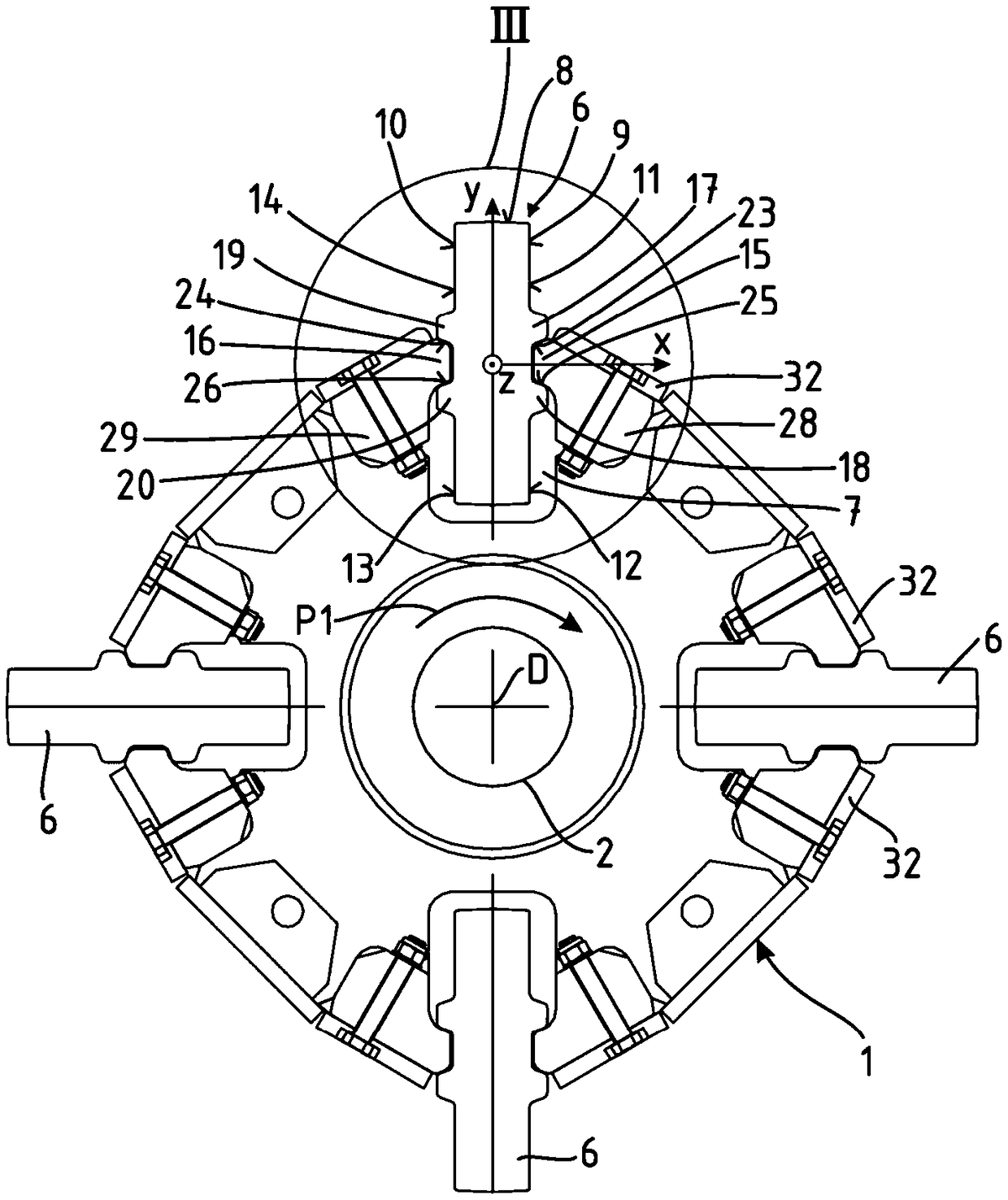

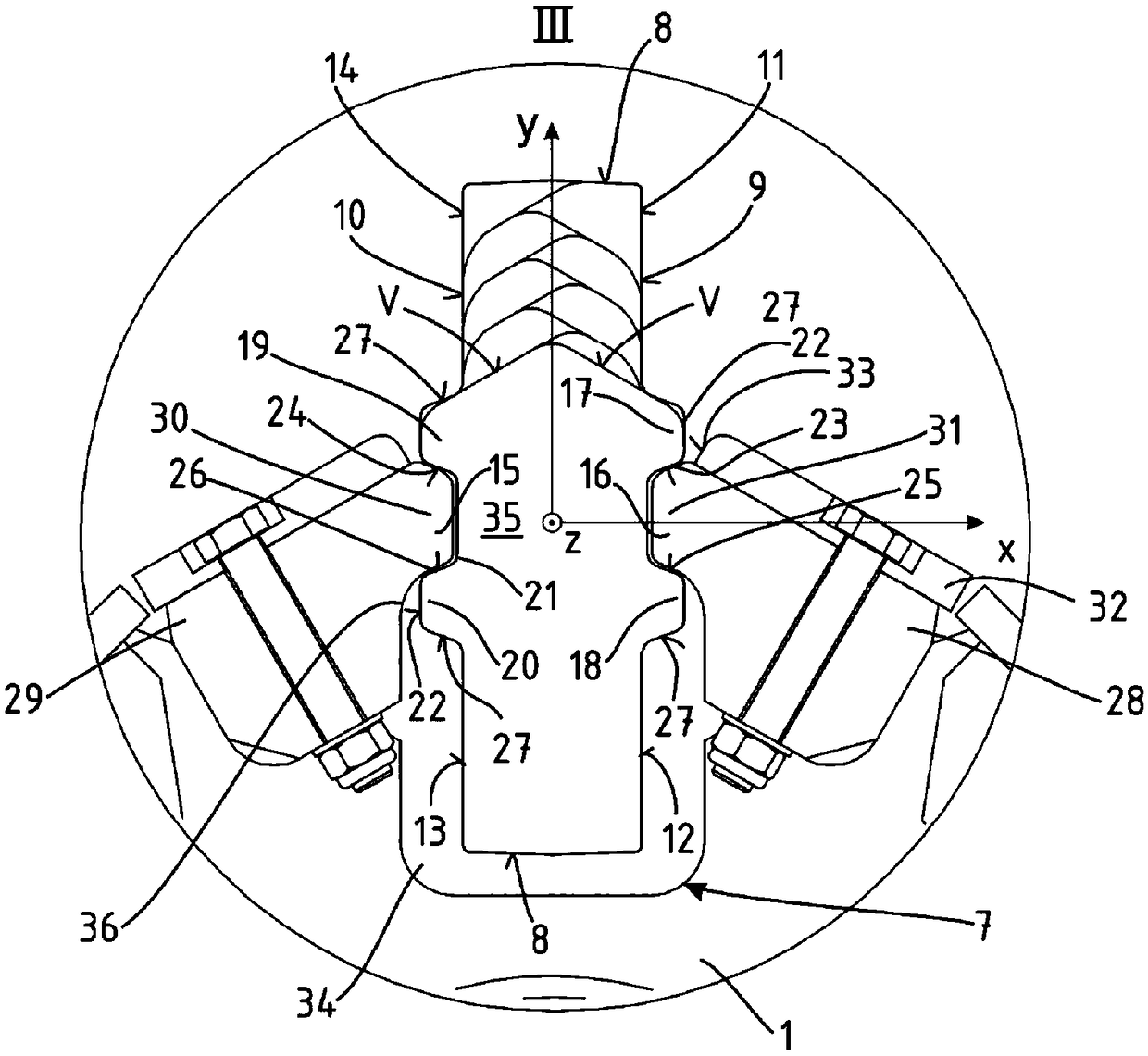

[0044] figure 1 The rotor 1 of the impact crusher, which is not shown further, is shown. The rotor 1 has a horizontal rotor shaft 2 which is mounted in bearings 3 , 4 . The rotor shaft 2 extends horizontally between the bearings 3 , 4 . The rotor shaft is driven by a belt pulley 5 . Strike bars 6 are arranged distributed over the circumference on the rotor 1 . exist figure 1 The uppermost beating strip 6 in the drawing plane of , like all other beating strips 6 , extends parallel to the axis of rotation D of the rotor shaft 2 .

[0045] In the following description of the strike bar 6 reference is made to a Cartesian coordinate system. The origin of the coordinate system is located at the center of the strike bar 6 , that is to say at half the length (z axis), height (y axis) and width (x axis) of said strike bar 6 . With respect to the uppermost striker bar 6 in the plane of the drawing and perpendicularly to the axis of rotation D, the x-direction runs tangentially to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com