High-precision rapid gas mixing device capable of rotating reversely

A high-precision, reverse-rotation technology, applied in mixers with rotating containers, mixers, mixing methods, etc., can solve problems affecting the progress of experiments and the accuracy of experimental results, threatening people's lives, and affecting safe production. The effect of increasing the degree of gas flow and diffusion, good mixing effect and strong practicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

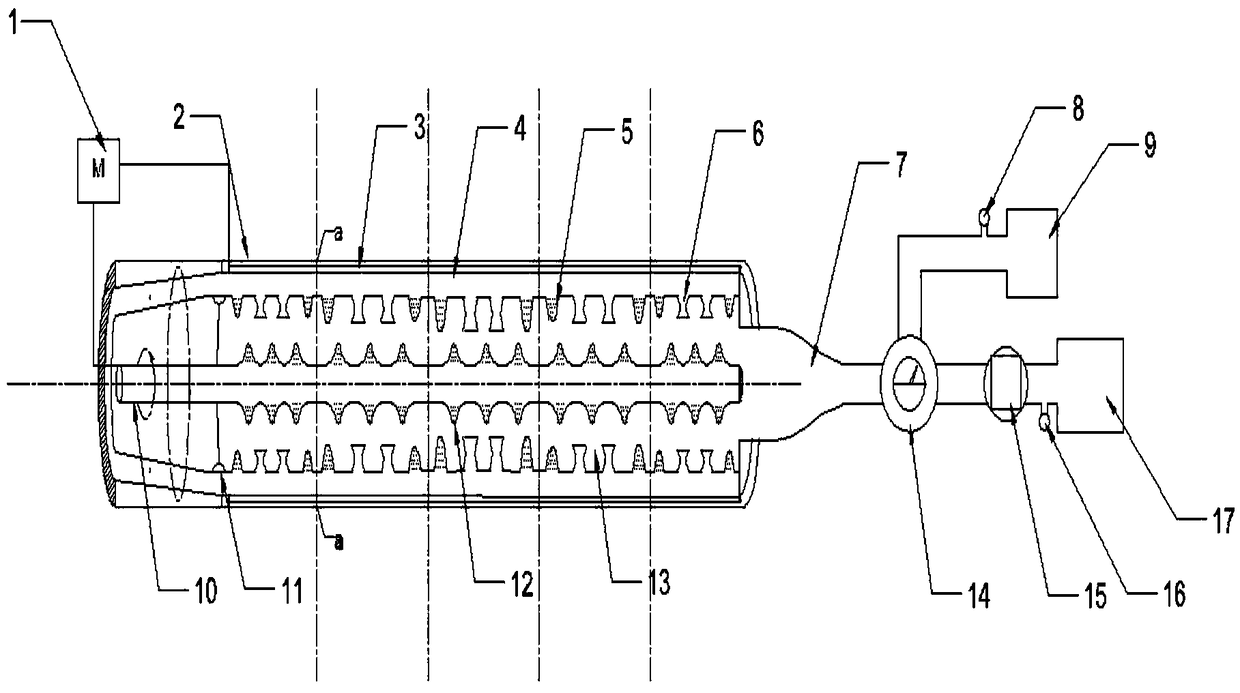

[0021] The present invention will be further described below in conjunction with accompanying drawing:

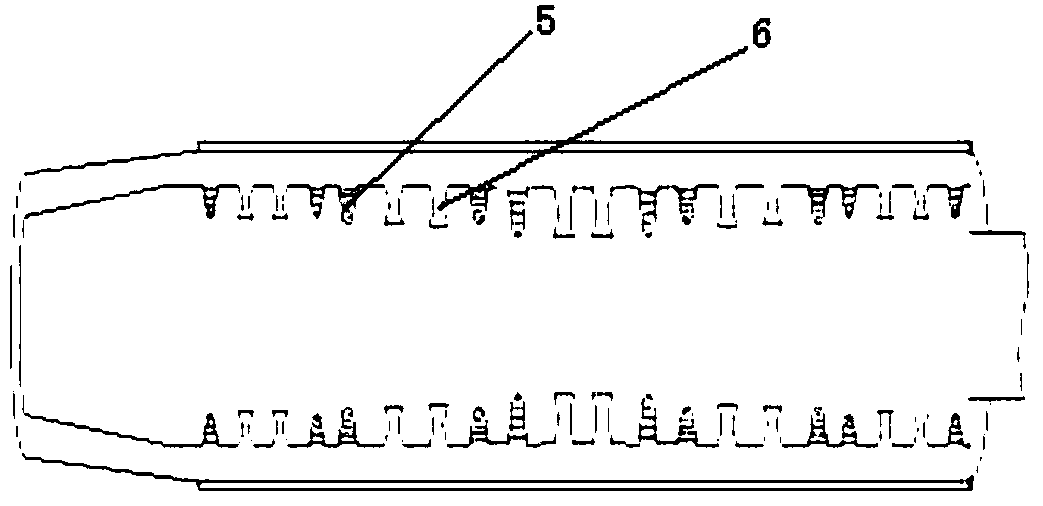

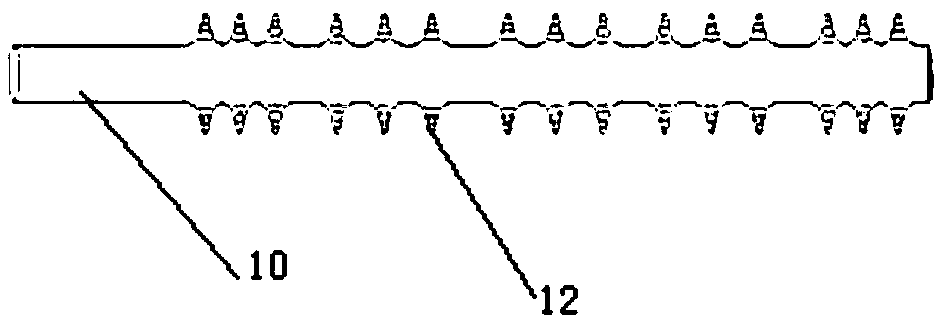

[0022] The invention is a high-precision and fast gas mixing device based on reverse rotation. The high-precision and fast gas mixing device of reverse rotation provides reverse rotation power for the flow channel on the side of the outer cavity and the flow channel on the side of the inner tube through a rotating motor. Diffusion device with holes and enhanced flow around the Lafal nozzle to improve the gas mixing effect, use the gas mixing mode switching switch to switch the gas mixing mode between two streams and three streams, and install the two different modes of gas mixing through the channel switching valve Into two different storage bottles, and the concentration can be detected by the concentration detection device, and the air pump is used to provide axial power when the two gases are mixed.

[0023] An embodiment of a high-precision rapid gas mixing device with ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com