Device and method for liquid-phase adsorption-type redox-method flue gas denitration

A liquid phase adsorption and reduction technology, applied in chemical instruments and methods, separation methods, gas treatment, etc., to achieve the effects of no reheating, simple equipment, and reduced operating costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

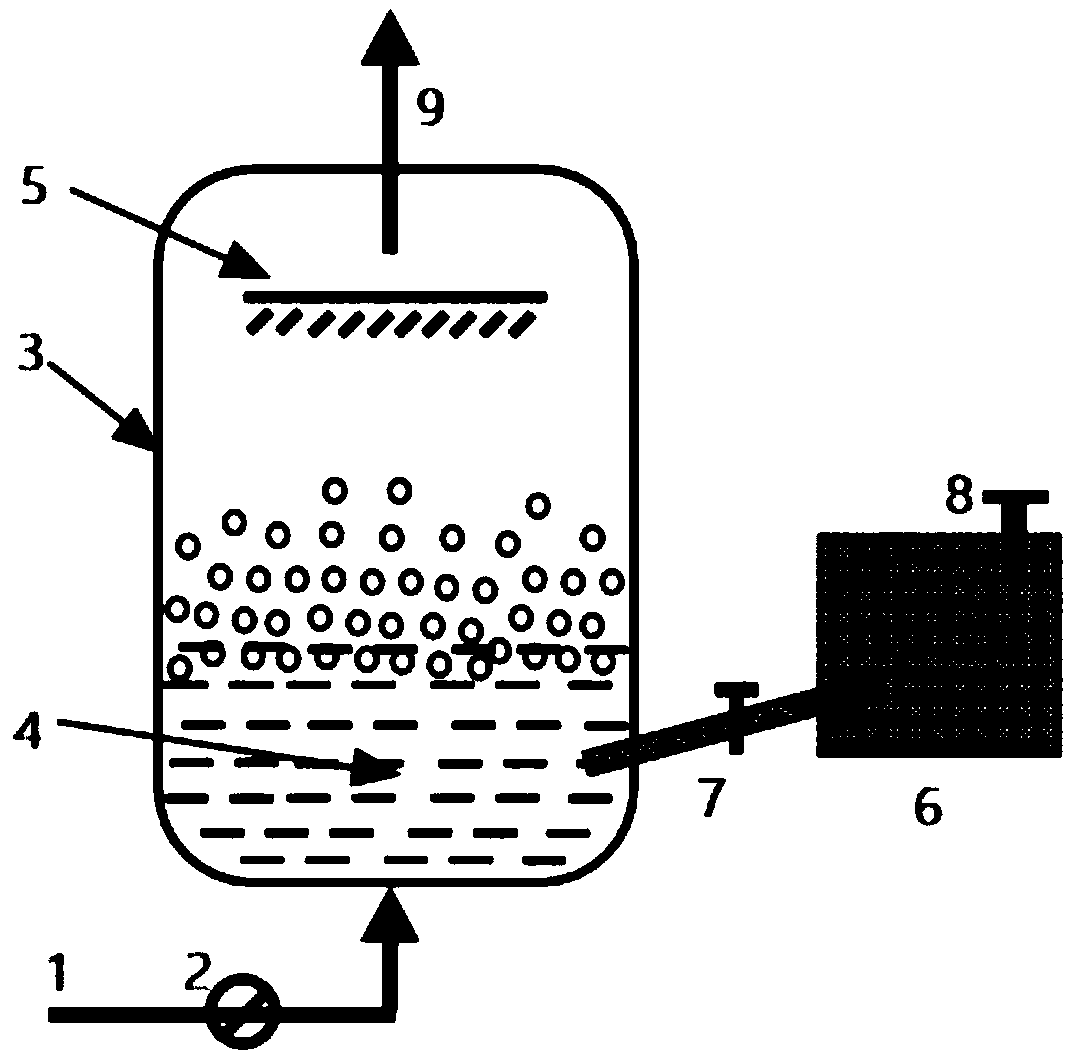

[0048] like figure 1 As shown, a liquid-phase adsorption type redox method flue gas denitration bubbling method device has a flue 1, a pressurized induced draft fan 2, a bubbling denitrification tower 3 and a tail flue 9 which are connected in sequence. The bubbling denitrification tower 3 is equipped with a denitration mixed liquid 4, and a mist eliminator 5 is arranged at the top of the tower. The flue gas 1 is blown into the bubbling denitrification tower 3 after passing through the pressurized induced draft fan 2. The NOx in the flue gas is removed by the denitrification mixture 4. After denitration, the flue gas is demisted by the mist eliminator 5, and finally discharged through the tail flue 9. . The denitration mixed liquid 4 is connected to the denitration liquid buffer tank 6 through the denitration liquid conveying pipe 7, and the denitration liquid conveying pipe 7 can control the conveying amount of the denitration liquid. A feeding port is arranged at the top o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com