Process method of TV speaker assembly production line

A process method and production line technology, applied in the technical field of TV speaker assembly production line, can solve the problems of cumbersome assembly process, influence of processing efficiency, increase of production cost, etc., and achieve the goal of improving product yield, improving processing efficiency and reducing error rate. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be described in detail below with reference to the accompanying drawings and examples. It should be noted that, in the case of no conflict, the embodiments of the present invention and the features in the embodiments can be combined with each other. For the convenience of description, if the words "up", "down", "left" and "right" appear in the following, it only means that the directions of up, down, left and right are consistent with the drawings themselves, and do not limit the structure.

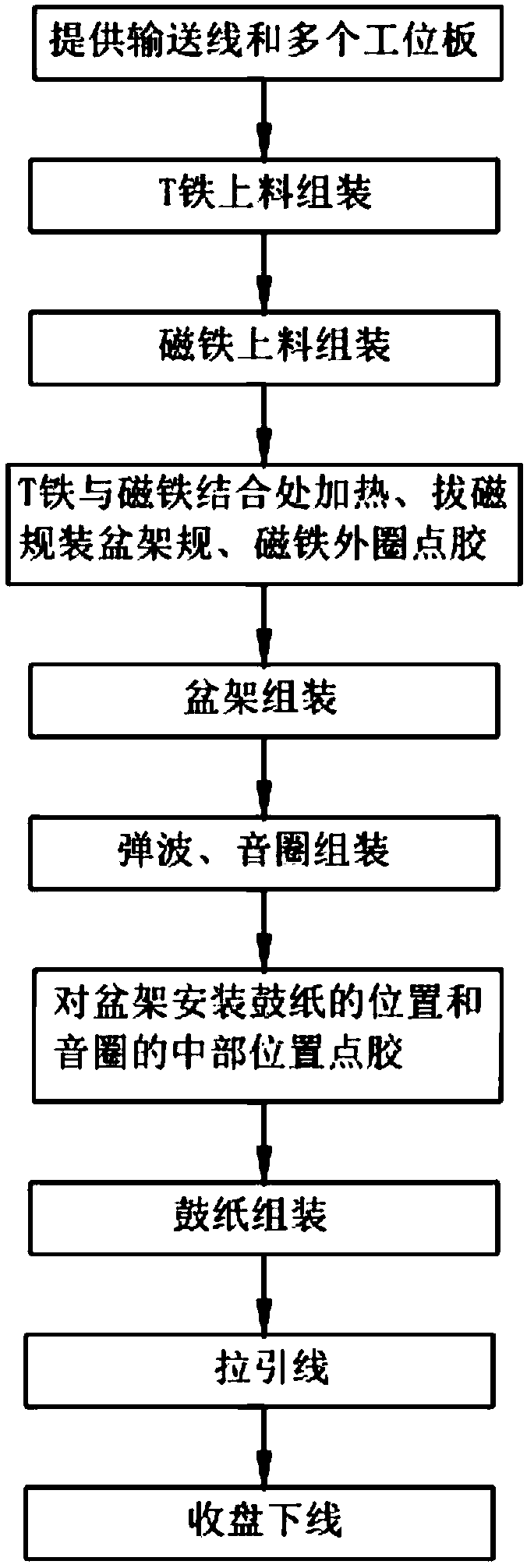

[0028] like figure 1 As shown, the process method of the TV horn assembly production line provided by the present embodiment comprises the following steps:

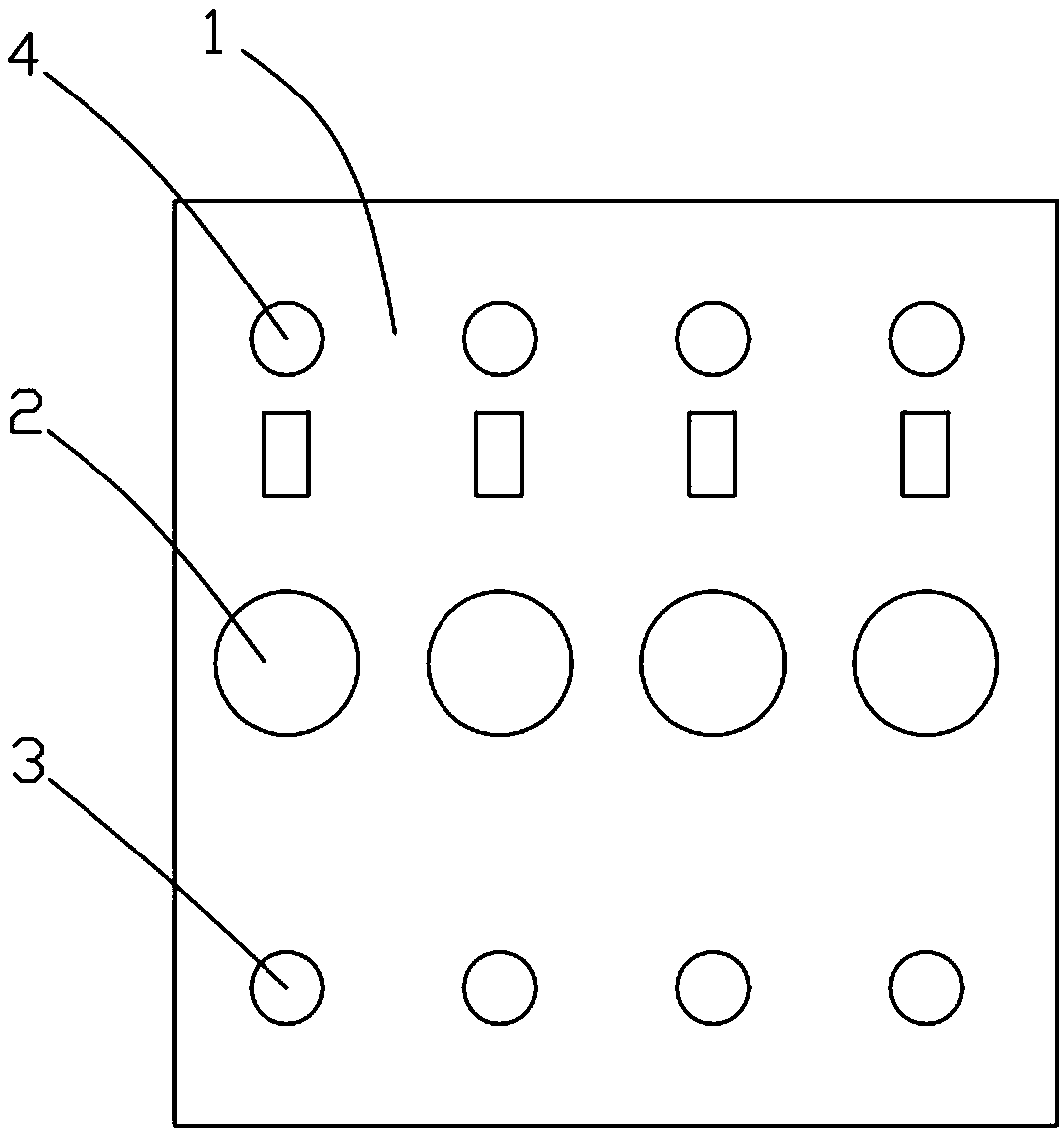

[0029] Step 1, providing a conveying line and a plurality of station boards, the conveying line is a linear line body circulation structure, and a plurality of the station boards go back and forth on the conveying line, such as figure 1 As shown, the middle part of the station board 1 is provided w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com