A nanometer Zn @ C negative electrode material for secondary zinc-based battery and preparation method thereof

A zinc-based battery and negative electrode material technology, which is applied in secondary batteries, battery electrodes, nanotechnology for materials and surface science, etc., can solve the problem that battery cycle performance needs to be further improved, and limit the specific surface area and flatness of negative electrode materials. problems, to achieve the effect of increasing the electrochemical reaction area, strong dendrite growth inhibition ability, and good binding force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

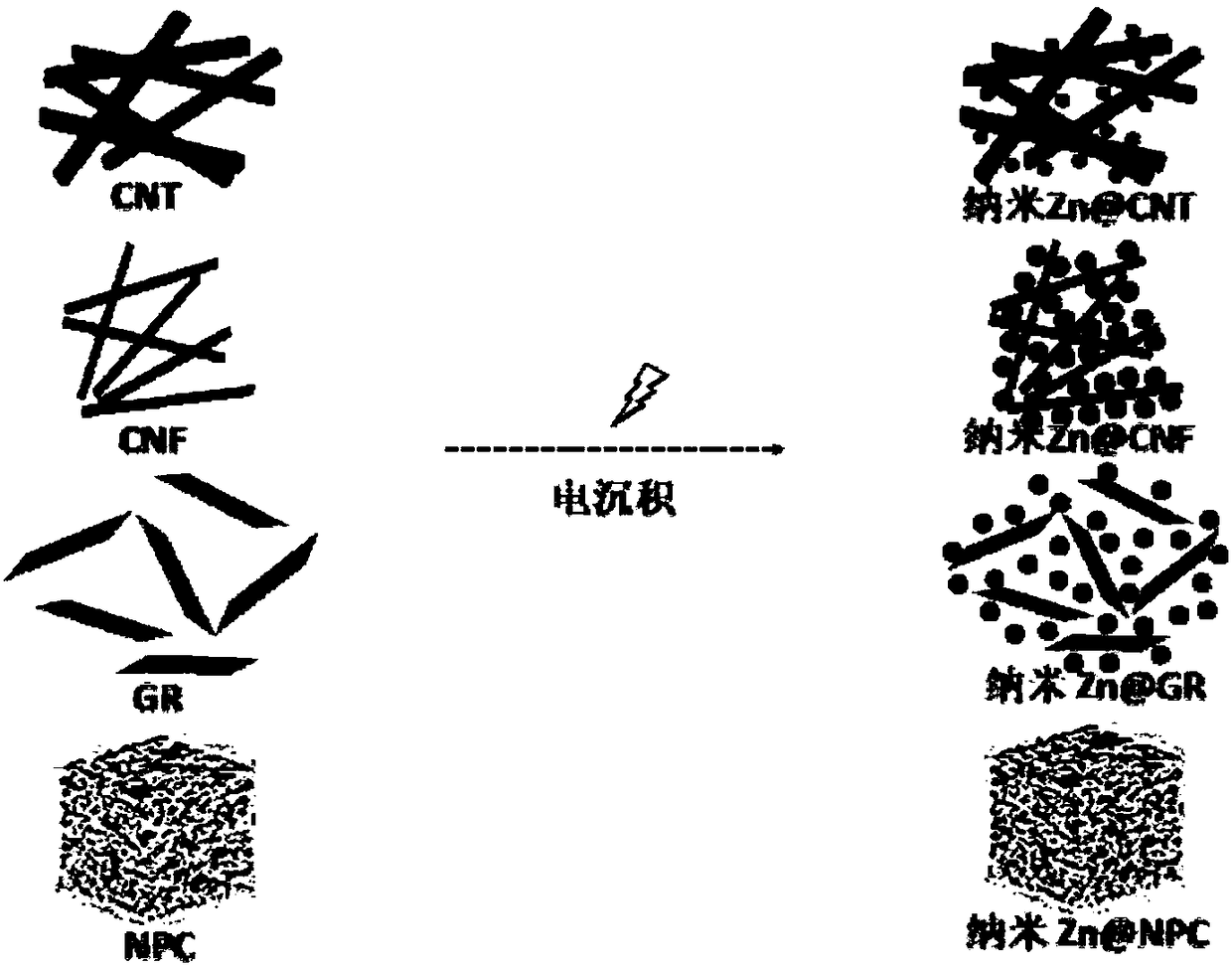

[0037] figure 1 The preparation process of the nano-Zn@C negative electrode material for secondary zinc-based batteries in the embodiment of the present invention is shown. In this embodiment, the nano-carbon material is CNT, which has a high specific surface area and can significantly increase the electrochemical reaction area of the composite electrode. And it can also be used as a conductive framework for composite electrodes to transport electrons, and is suitable for compounding with nano-zinc. Concrete preparation method is as follows:

[0038] 1. Ultrasonic degreasing of CNTs with a size of 2cm (length) × 2cm (width) × 100μm (thickness) in NaOH 10g / L solution for 1min, and then rinsed with deionized water;

[0039] 2. Treat CNT in HCl 0.2mol / L solution at room temperature for 10s, and then rinse with deionized water;

[0040] 3. According to the concentration of zinc sulfate 100g / L, boric acid 20g / L, and polyacrylamide 1g / L, use deionized water to configure the elec...

Embodiment 2

[0046] The difference between this embodiment and embodiment 1 is that CNF is used instead of CNT. Refer to Example 1 for the remaining parameters and steps.

Embodiment 3

[0048] The difference between this embodiment and embodiment 1 is that GR is used instead of CNT. Refer to Example 1 for the remaining parameters and steps.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| surface roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com