Electrode suspension type capacitive pressure sensor adopting assembled fixed electrode

A pressure sensor and assembled technology, applied in the direction of fluid pressure measurement using capacitance change, can solve the problems of high production cost and low production efficiency, and achieve the effect of eliminating temperature drift, buffering welding stress and thermal stress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

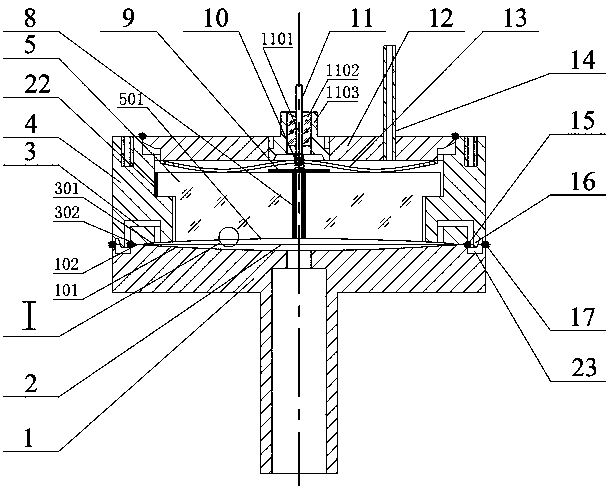

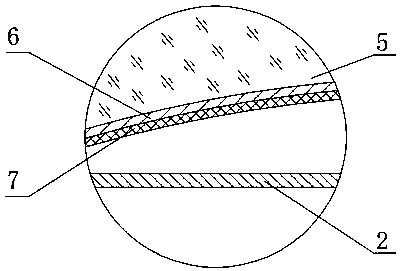

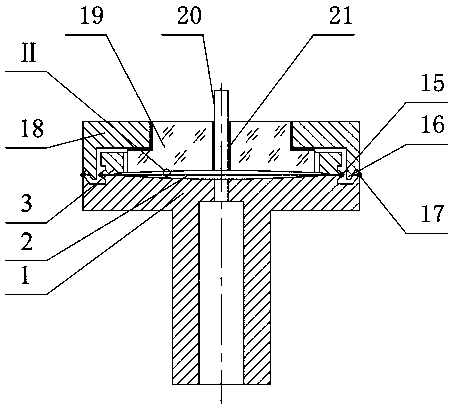

[0038] according to figure 1 , figure 2 , detailing the specific structure and manufacturing method of the present invention.

[0039] The electrode-suspended capacitive pressure sensor using assembled fixed electrodes includes a fixed-electrode single-end suspension structure and a moving electrode single-end suspension structure that are relatively welded with thin-walled edges. The moving electrode single-end suspension structure includes a pressure guide The port support 1, the upper clamping ring 3, and the movable electrode 2 fixedly supported by clamp welding between the port support 1 with pressure induction and the upper clamping ring 3. The upper surface of the bearing 1 with a pressure introduction port is provided with a parabolic concave surface A101 corresponding to the movable electrode 2 and an annular fixed support plane A102 located on the outer periphery of the parabolic concave surface A101, and the lower surface of the upper clamping ring 3 is provided ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com