Graded damping vibration reduction device for rolling mill

A vibration damping device and damping technology, which is applied in the direction of shock absorbers, liquid shock absorbers, shock absorbers, etc., can solve the problems of not fully considering the performance differences, not applicable to vibration suppression effects, and affecting product quality, etc., to achieve good results The effect of market development and promotion prospects, compact structure, and small installation and maintenance workload

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The present invention will be further elaborated below in conjunction with accompanying drawing:

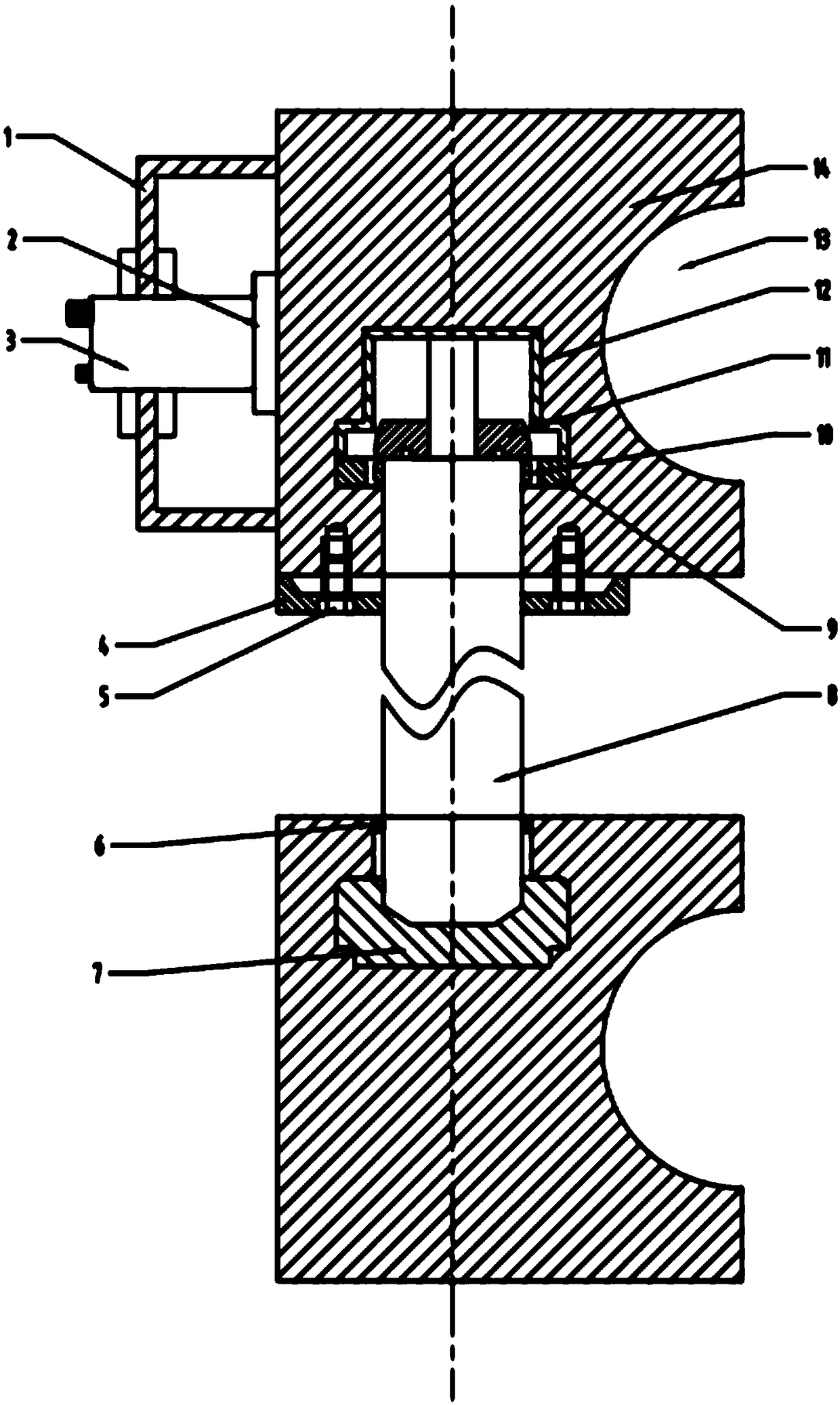

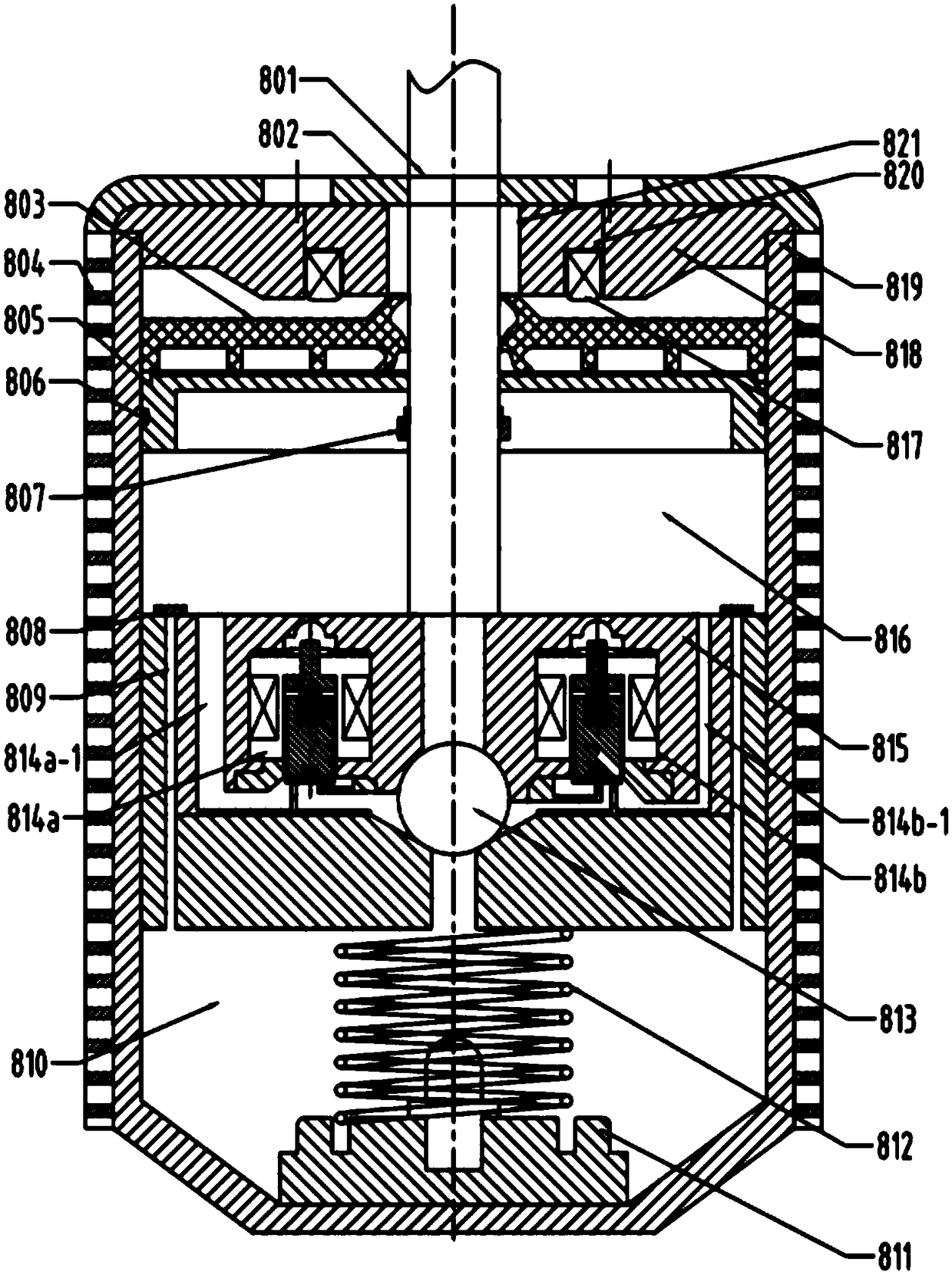

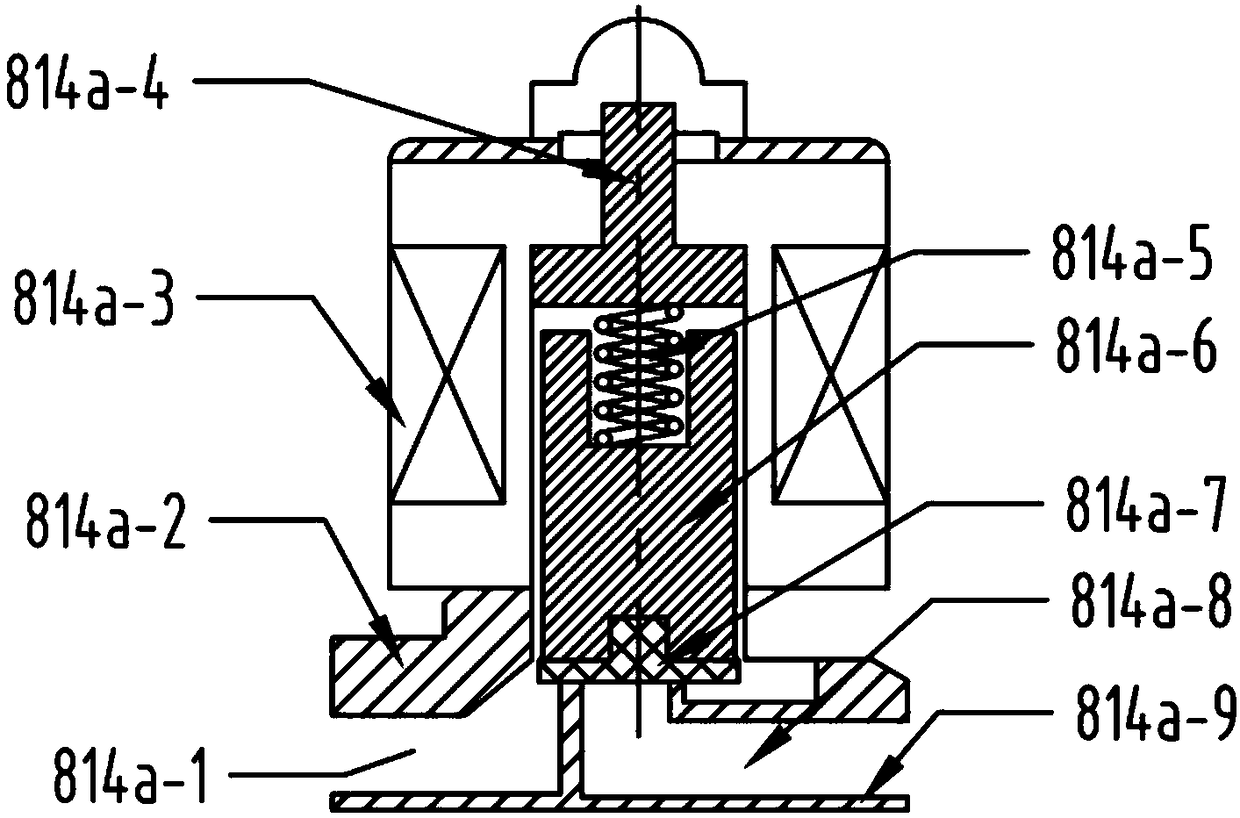

[0035] like figure 1 As shown, the installation assembly of a graded damping and vibration reduction device 8 for a rolling mill of the present invention includes a sealing end cover 4, a set screw 5, a dust-proof ring 6, an elastic adjustment pad 7, a fixed block 9, an adjustment pad 10, a stopper Push block 11, outer protective shell 12, upper work roll 13, upper work roll chock 14. The vibration sensor 3 is embedded in the sensor bracket 1 and fixedly connected to the side of the upper work roll chock 14 through the sensor base 2 .

[0036] The bottom end of the graded damping and vibration reduction device 8 is directly seated in the elastic adjustment pad 7, and is sealed with the lower work roll bearing seat by a dust-proof ring 6. The elastic adjustment pad 7 can reduce the piston rod 801 to a certain extent. itinerary.

[0037] The sealing end cover 4 is fixed o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com