A magneto-rheological valve-controlled damping controllable shock absorber

A magneto-rheological valve and shock absorber technology, which is applied in the field of parts and components, can solve problems such as the inability to take into account both vehicle ride comfort and handling stability, the damping force cannot achieve the vibration reduction effect, and the failure of sealing components, so as to avoid temperature Too high and premature failure, sensitive vibration response, attenuation of vibration and shock effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

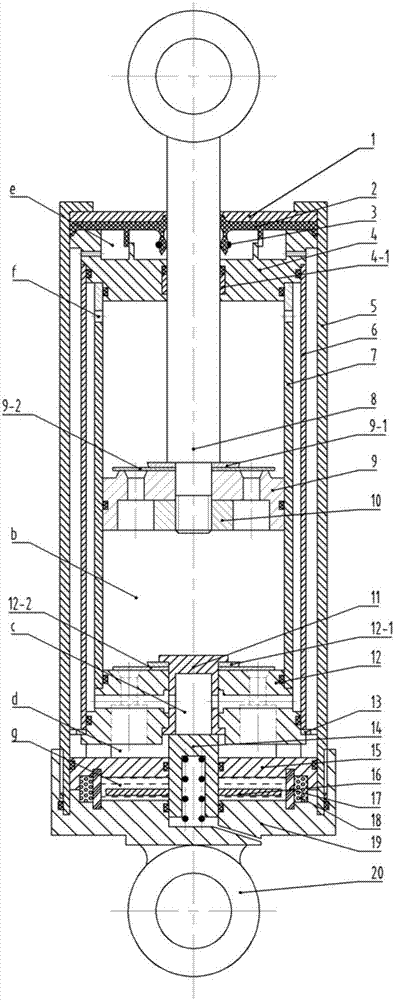

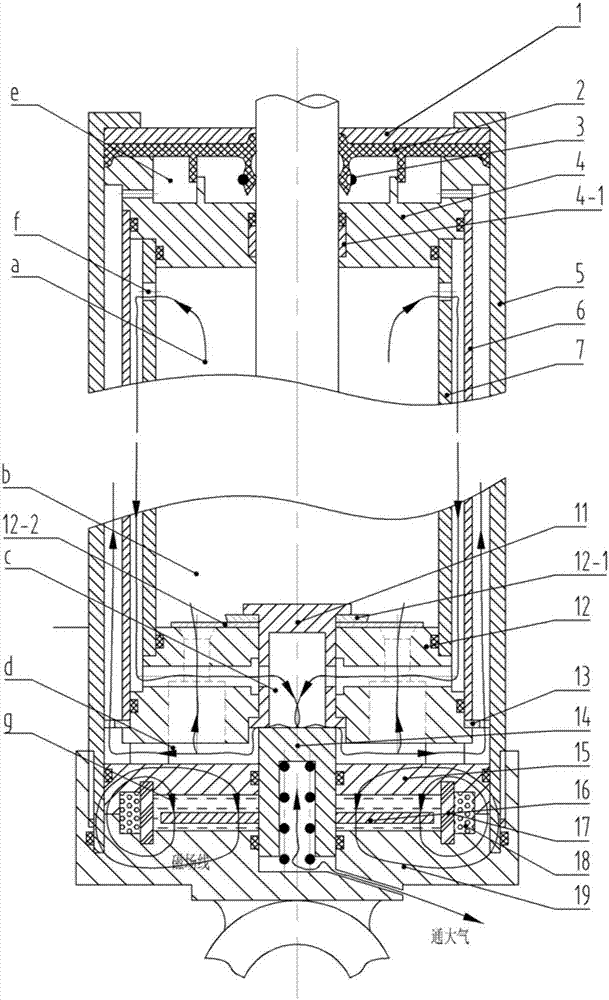

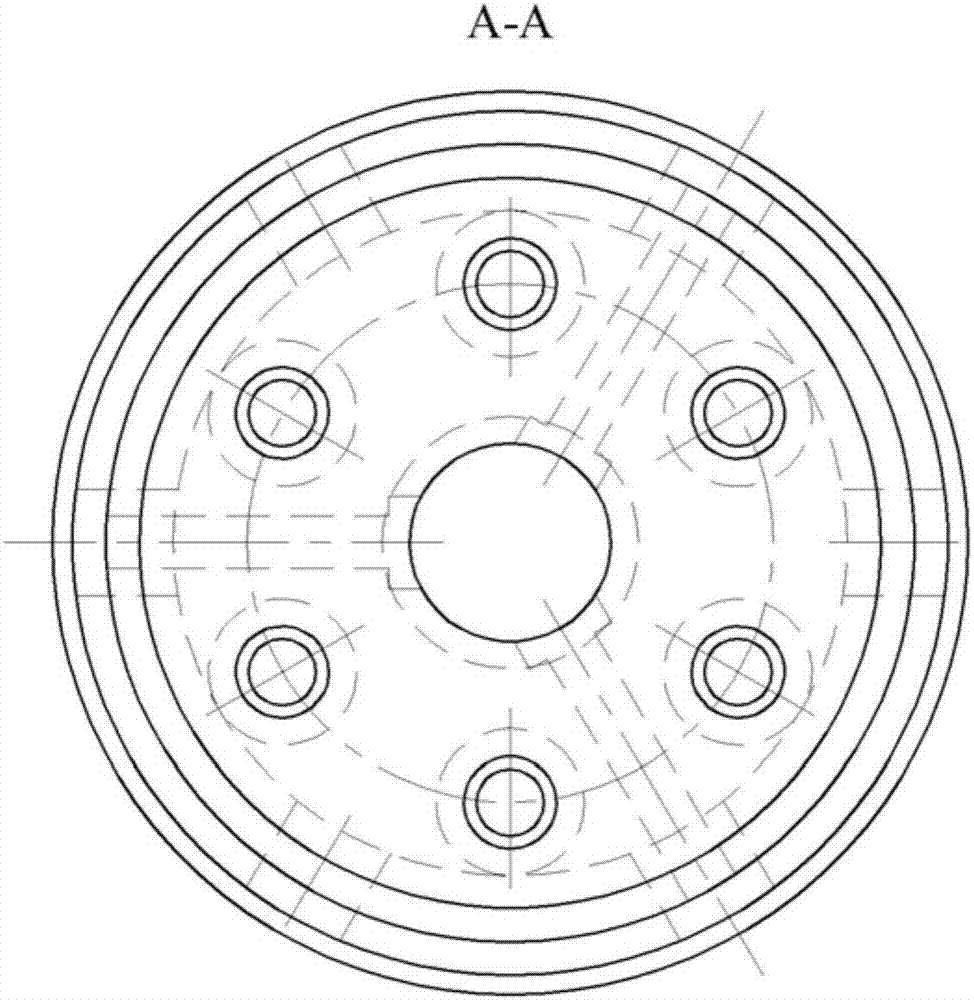

[0027] The technical features of a magneto-rheological valve-controlled damping controllable shock absorber of the present invention will be further described in conjunction with the accompanying drawings and embodiments:

[0028] figure 1 It is a schematic diagram of the overall structure of an embodiment of the present invention. Its structure is simple. The damping force adjustment range and adjustment characteristics can be further adjusted by changing the size of the plane throttle valve port. Combined with the electronic control system, the control accuracy can be improved to ensure its working stability. .

[0029] like figure 1 As shown, the shock absorber mainly includes a guide assembly 4, an oil storage cylinder 5, an intermediate cylinder 6, a working cylinder 7, a piston rod 8, a piston valve assembly composed of a piston 9 and an internally threaded piston fixing block 10, and a bottom valve The assembly 12 and the magnetorheological valve composed of the magne...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com