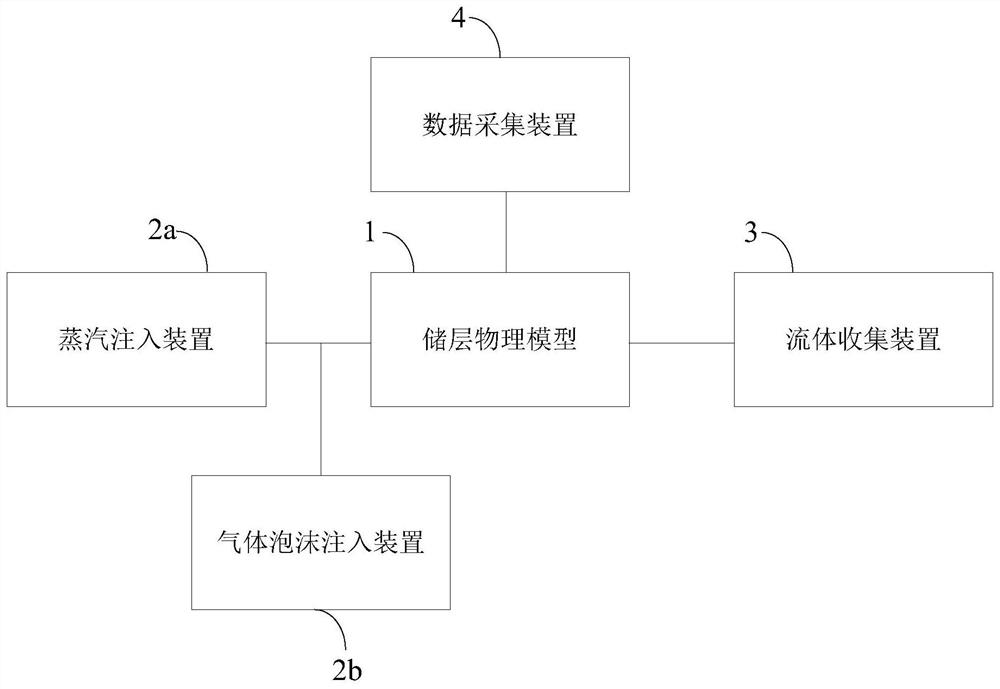

Physical simulation system and method for steam flooding heavy oil recovery in vertical and horizontal wells

A combined steam and physical simulation technology, applied in the fields of production fluids, wellbore/well components, earthwork drilling, etc., can solve the problems of expanding steam sweep volume, uneven production of horizontal well sections, and low single-layer control reserves, etc. Expand the swept volume, increase the swept area between wells, and reduce the effect of single well inrush

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] Moreover, for the convenience of description, some embodiments of the present application may use words such as "above", "under",

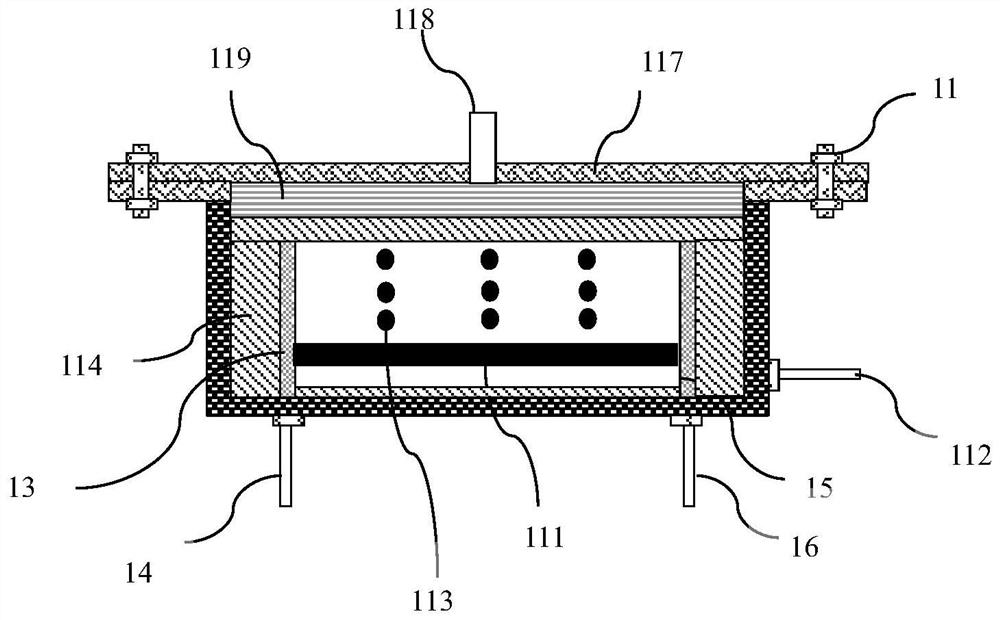

[0040] In an embodiment of the application, as shown in FIG. 2 and FIG. 3 , the upper cover plate 117 is provided with a pressure port 118,

[0049] In an embodiment of the present application, as shown in FIG. 4, the fluid collection device may include a

[0052] S501, successively carry out core saturated water and core saturated oil treatment to the physical model of the reservoir.

[0055] S502, carry out aging treatment to the reservoir physical model after the core is saturated with oil, to simulate super heavy oil.

[0061] It should also be noted that the terms "including", "comprising" or any other variation thereof are intended to cover non-exclusive

[0063] The above is only an embodiment of the application, and is not intended to limit the application. For those skilled in the art

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com