An induction heating device for gear surface quenching and a gear surface quenching method

An induction heating device and induction heating technology, applied in the field of heat treatment, can solve the problems of low heating efficiency and large energy consumption demand, and achieve the effects of improving production efficiency, safety, and heating depth

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

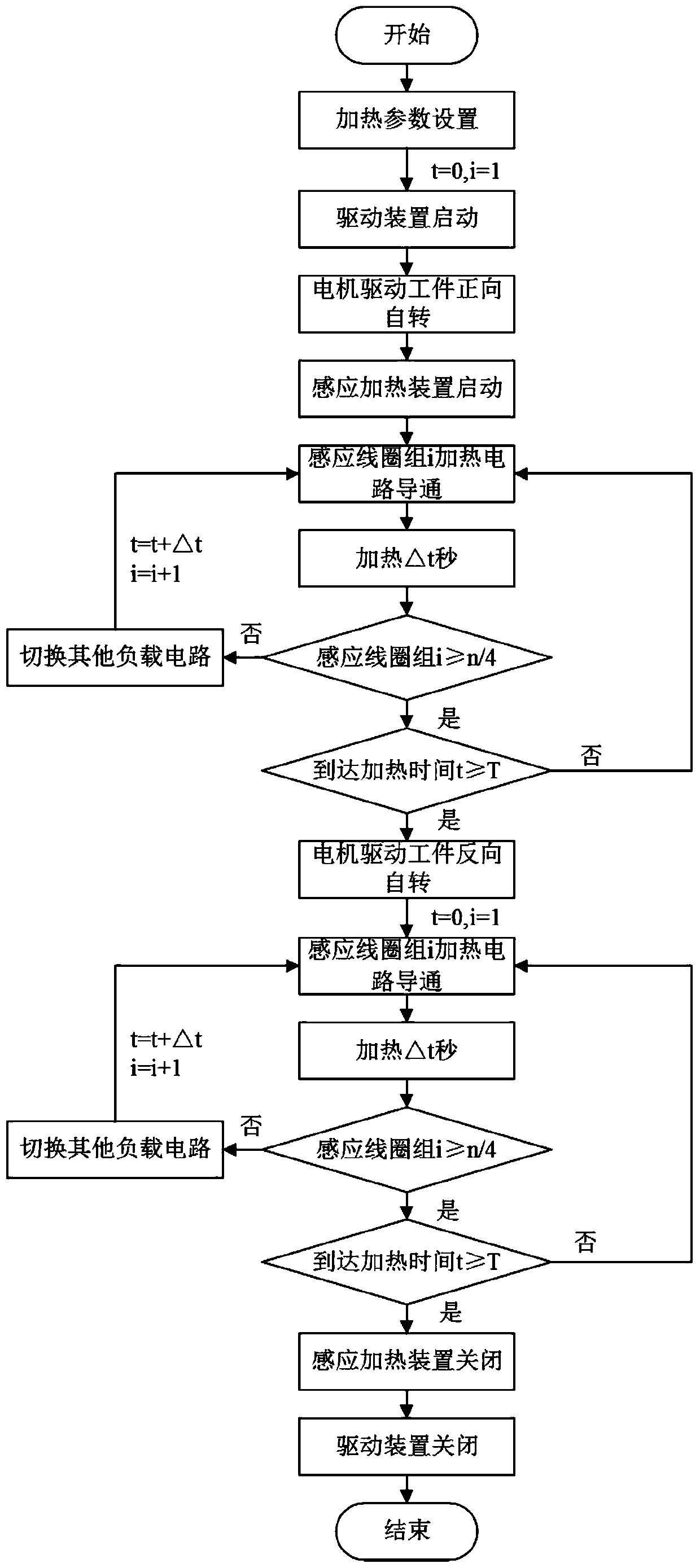

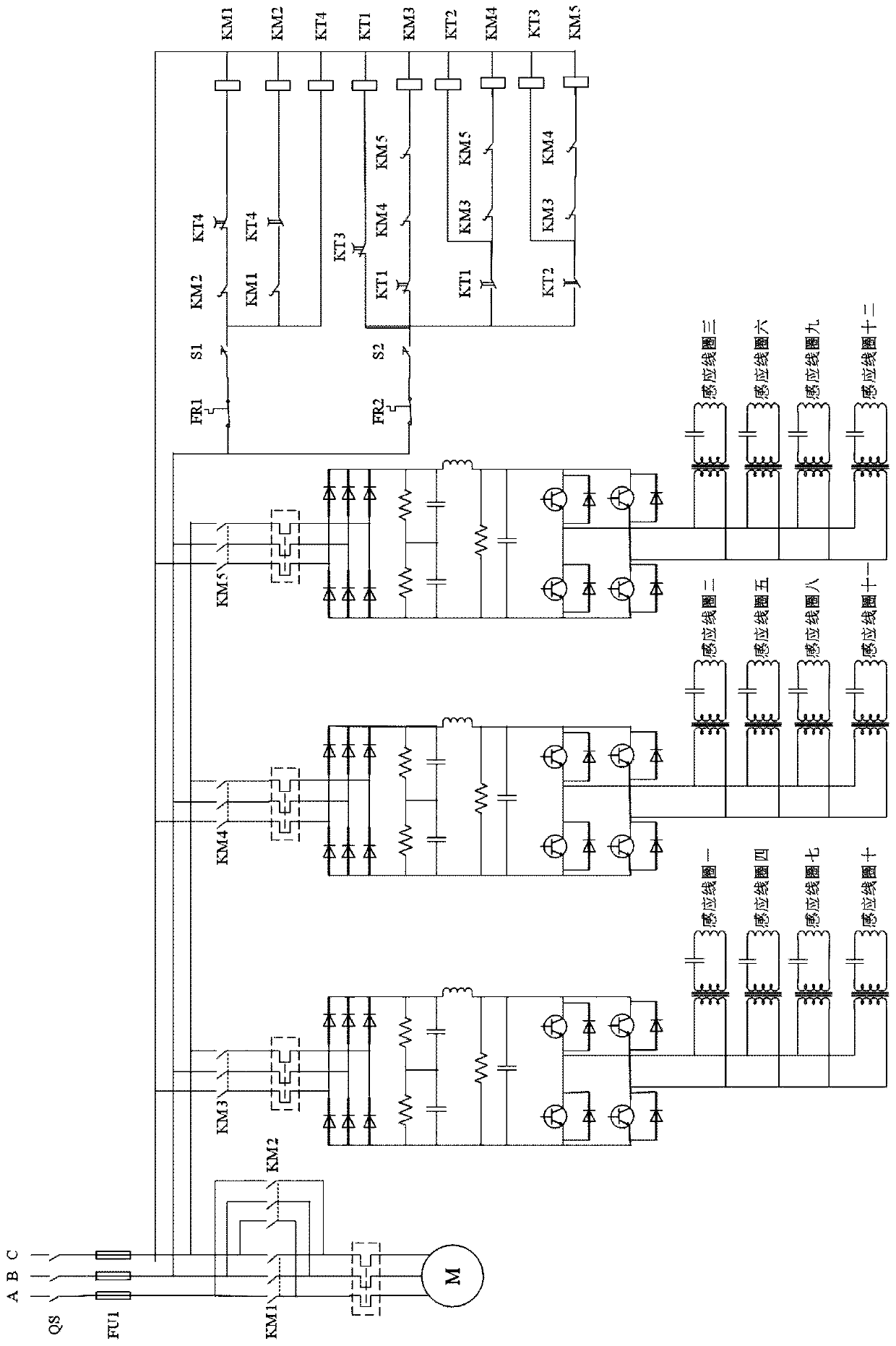

[0029] The present invention will be further described below in conjunction with accompanying drawing:

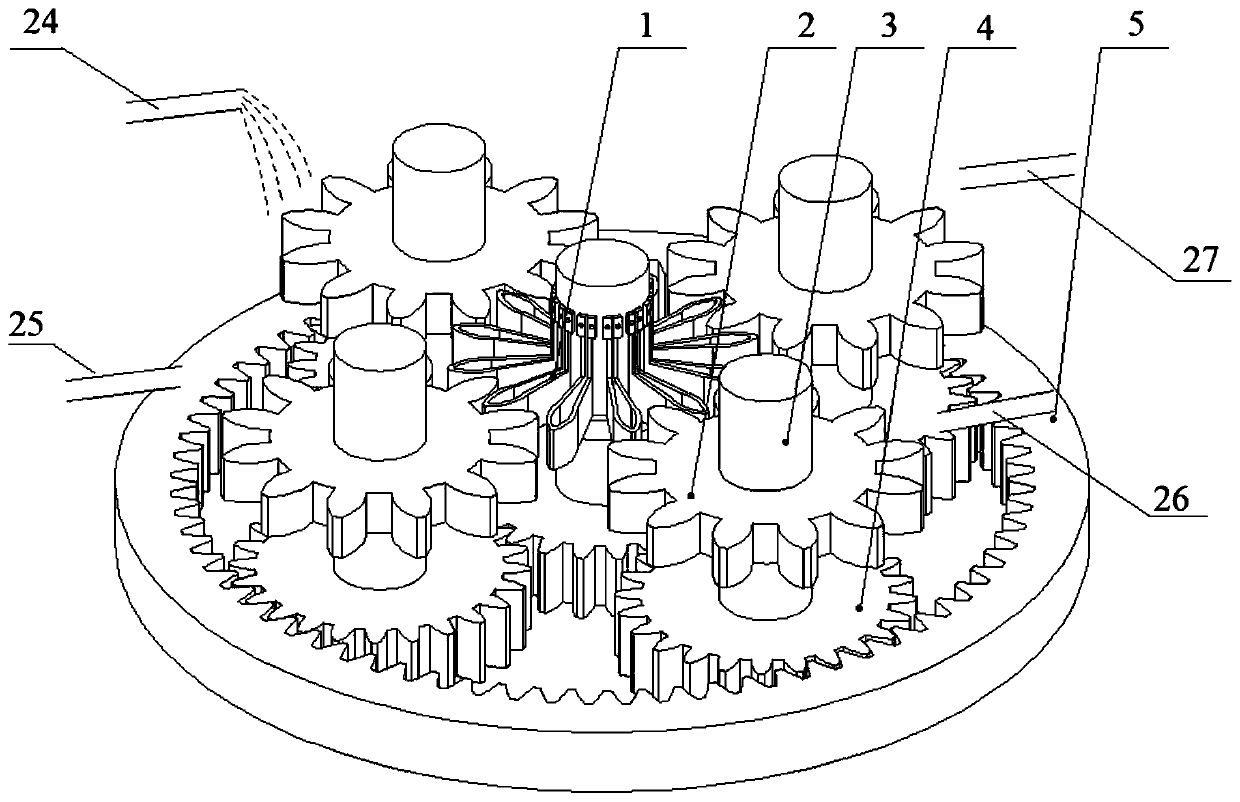

[0030] Such as Figure 3-5 As shown, the present invention discloses an induction heating device for gear surface quenching, which includes a heating gear shaft and a workpiece gear shaft that rotate in opposite directions, an induction heating gear 1 installed on the heating gear shaft, and an induction heating gear 1 installed on the workpiece gear shaft The gear workpiece 2 to be quenched on the surface; the induction heating gear 1 rotates coaxially with the heating gear shaft, and the gear workpiece 2 to be quenched rotates coaxially with the workpiece gear shaft; the induction heating gear 1 and the gear workpiece to be quenched 2 non-contact meshing; the teeth of the induction heating gear 1 are tooth-like induction coils.

[0031] Preferably, the heating gear shaft and the workpiece gear shaft are movably fixed on the base, the heating gear shaft is fixed with a ce...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com