Method for extracting chlorogenic acid from tobacco waste by combining high-voltage pulse electric field, microwaves and ultrasonic waves

A high-voltage pulsed electric field and ultrasonic technology, applied in the separation/purification of carboxylic acid esters, organic chemistry, etc., to achieve high extraction rate, short extraction time, and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

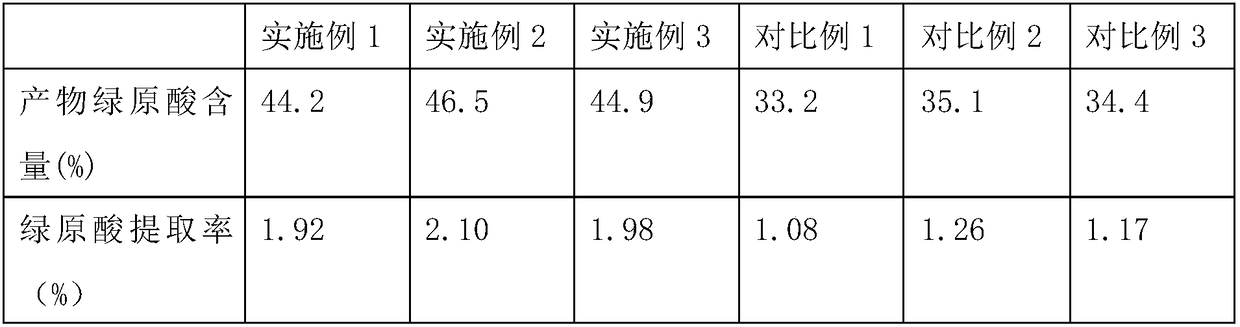

Examples

Embodiment 1

[0026] A method for extracting chlorogenic acid in tobacco waste in combination with high-voltage pulsed electric field microwaves and ultrasonic waves, comprising the following steps:

[0027] (1) 100g of tobacco waste is dried at 50°C, pulverized, and passed through a 20-mesh sieve;

[0028] (2) Put the pulverized tobacco waste in a solvent composed of 560mL of acetone and 560mL of water, and add 12g of branched 13-carbon Guerbet alcohol polyoxyethylene ether, stir well and let it stand for 1h. 200W, 10GHz microwave treatment twice, 30s each time, and then 1ms under the high-voltage pulsed electric field with a field strength of 25kV / cm and a pulse frequency of 400pps, and then use a hydrochloric acid solution with a molar concentration of 0.1mol / L Adjust the pH to 5, extract for 30 minutes under ultrasonic waves with a power of 300W and a frequency of 30KHz, filter with suction, collect the filtrate, repeat the above steps to extract the filter residue once more, filter wit...

Embodiment 2

[0032] A method for extracting chlorogenic acid in tobacco waste in combination with high-voltage pulsed electric field microwaves and ultrasonic waves, comprising the following steps:

[0033] (1) 100g of tobacco waste is dried at 55°C, pulverized, and passed through a 30-mesh sieve;

[0034] (2) Put the pulverized tobacco waste in a solvent composed of 524mL of acetone and 786mL of water, and add 24g of 12-14 carbon primary alcohol polyoxyethylene ether, stir well and let it stand for 1.5h. Treat 3 times under 15GHz microwave, 25s each time, and then treat 2ms under high-voltage pulsed electric field with field strength of 32kV / cm and pulse frequency of 500pps, and then adjust pH to 5.5 with hydrochloric acid solution with molar concentration of 0.1mol / L , extract 25min under ultrasonic waves with a power of 350W and a frequency of 35KHz, suction filtration, and collect the filtrate. Refrigerate in a refrigerator at 3°C for 36 hours, remove the bottom precipitate, recover...

Embodiment 3

[0038] A method for extracting chlorogenic acid in tobacco waste in combination with high-voltage pulsed electric field microwaves and ultrasonic waves, comprising the following steps:

[0039] (1) drying the tobacco waste at 60°C, pulverizing, and passing through a 40-mesh sieve;

[0040] (2) Place the pulverized tobacco waste in a solvent mixed with 538mL acetone and 1076mL water, add 42g fatty acid methyl ester polyoxyethylene ether, stir well and let it stand for 2h, at a power of 300W, a frequency of Treat 3 times under 20GHz microwave, 20s each time, then treat 1ms under the high-voltage pulsed electric field with field strength 40kV / cm and pulse frequency 600pps, and then adjust the pH to 6 with a hydrochloric acid solution with a molar concentration of 0.1mol / L. Power is 400W, frequency is 40KHz ultrasonic extraction 20min, suction filtration, collect filtrate, filter residue repeat above-mentioned steps to extract again, suction filtration, merge twice filtrate, aband...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com