Method for mixing and vaporizing hydrogen fluoride and chlorohydrocarbon

A technology of chlorinated hydrocarbons and hydrogen fluoride, which is applied in chemical instruments and methods, preparation of halogenated hydrocarbons, and preparation of dehydrohalogenation. Conducive to rapid and effective vaporization, rapid and effective vaporization, enhanced mass transfer and heat transfer effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

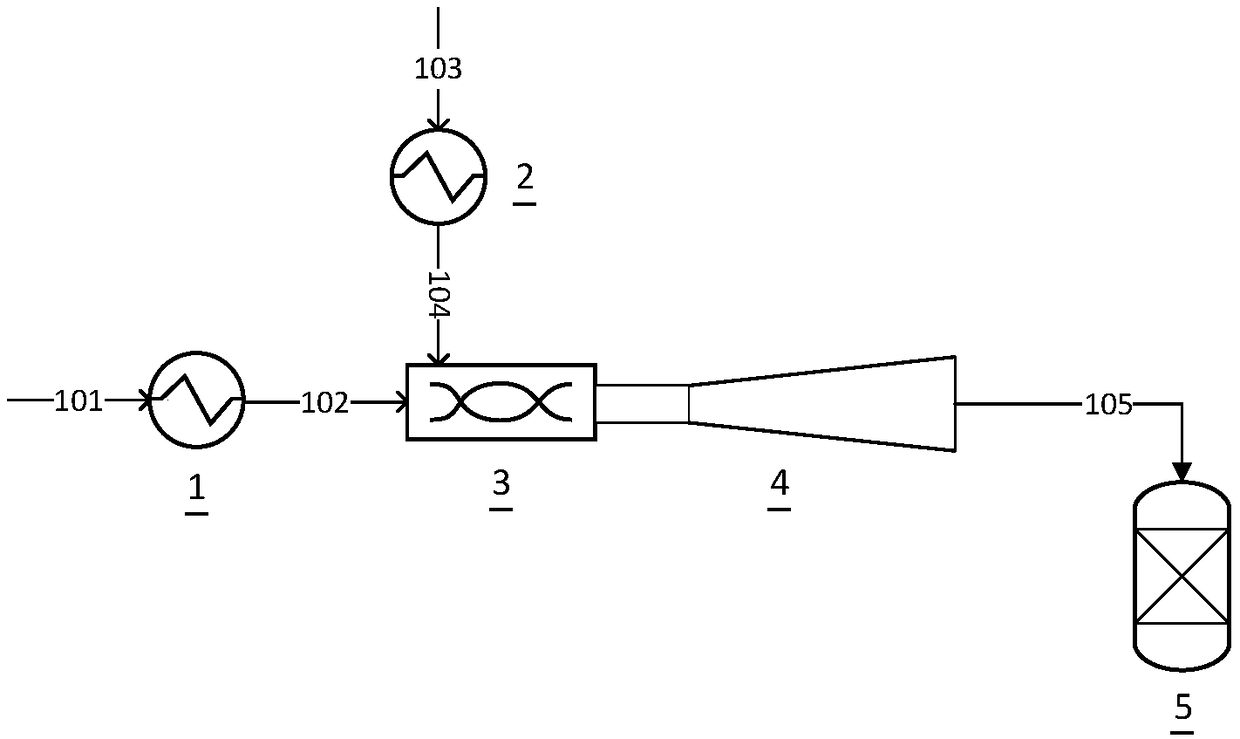

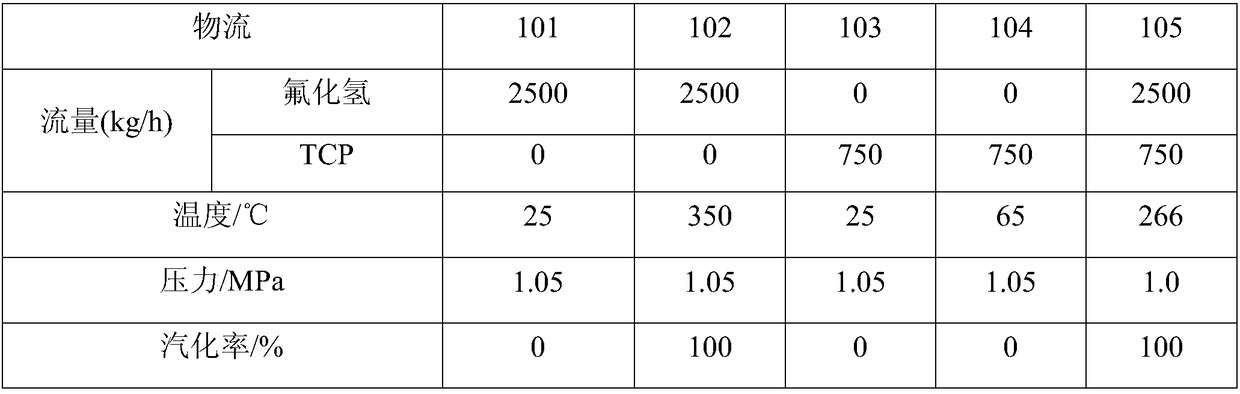

[0022] Take the vaporization process in the synthesis of HCFO-1233xf by gas-phase fluorination of 1,1,2,3-tetrachloropropene (TCP) as an example. This reaction requires the temperature of the material entering the reactor to be 260°C and the pressure to be 1.0MPA.

[0023] The static mixer 3 is a SK type static mixer, the shell, flange and mixing unit are all made of SUS304, the diameter of the equipment is 80mm, and the total length of the equipment is 500mm; the vaporizer 4 is a Venturi tube, and the gas velocity of the material in the throat diameter section The diameter of the corresponding throat diameter section is 50mm, the length of the throat diameter section is 100mm, and the length of the expansion section is 500mm.

[0024] Liquid hydrogen fluoride is heated to 350°C by HF heater 1 and enters static mixer 3. Liquid TCP is preheated to 65°C by TCP preheater 2 and then enters static mixer 3. The molar ratio of hydrogen fluoride to TCP is 30:1. The mixture is mixed by...

Embodiment 2

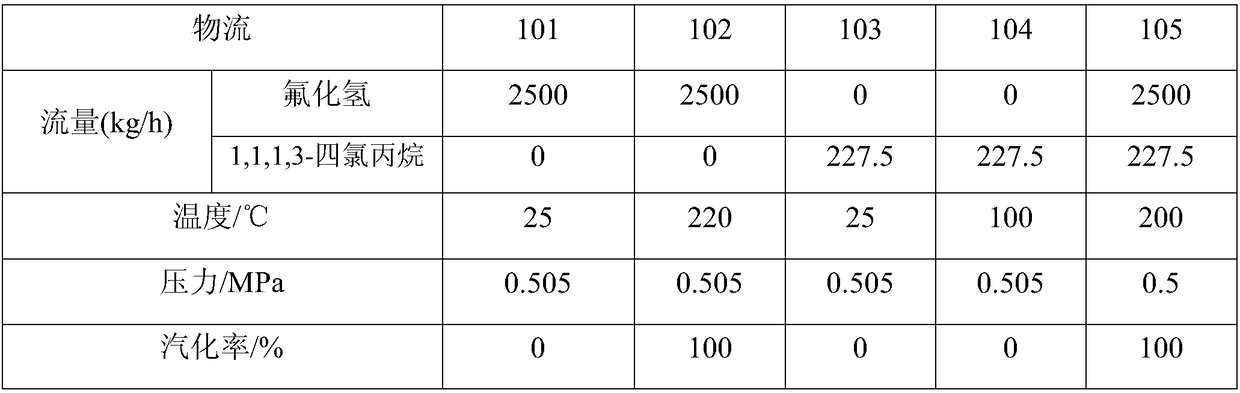

[0028] Example 2 takes the vaporization process in the synthesis of trifluoropropene by gas phase fluorination of 1,1,1,3-tetrachloropropane as an example. This reaction requires the temperature of the material entering the reactor to be 200°C and the pressure to be 0.5MPA.

[0029] The static mixer 3 is a SV-type static mixer, the shell, flange, and mixing unit are all made of SUS304, the diameter of the equipment is 60mm, and the total length of the equipment is 500mm; the vaporizer 4 is a Venturi tube, and the gas velocity of the material in the throat diameter section The diameter of the corresponding throat diameter section is 45mm, the length of the throat diameter section is 180mm, and the length of the expansion section is 1500mm.

[0030] Liquid hydrogen fluoride enters static mixer 3 after being heated to 220°C by HF heater 1, liquid 1,1,1,3-tetrachloropropane enters static mixer 3 after being preheated to 100°C by TCP preheater 2, hydrogen fluoride and The molar rat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com