A kind of zirconium sol and its preparation method and application

A technology of zirconium sol and zirconium salt, which is applied in the field of preparation of zirconium sol, and can solve the problems of not providing zirconium sol, not providing a suitable method for zirconium sol, poor performance, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

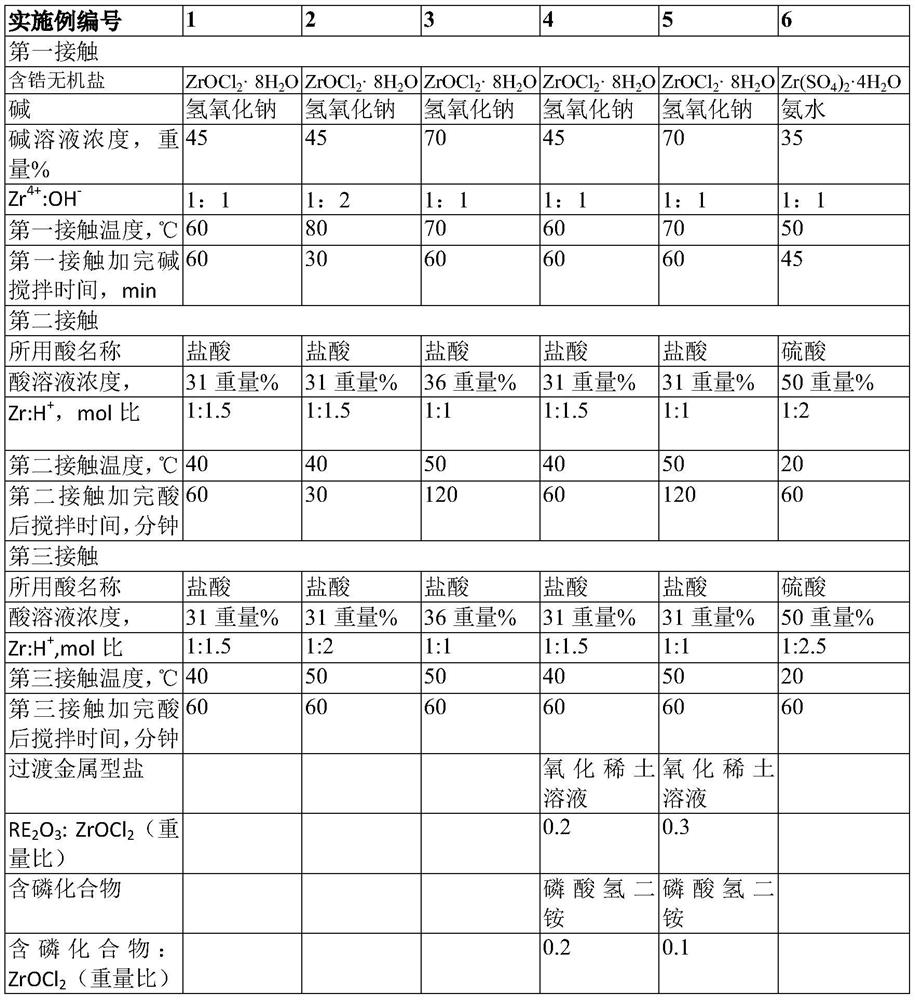

[0055]In one embodiment, the zirculatomal salt containing a zirconium salt with the base solution at a T1 temperature in step (1), and T1 is 50 to 80 ° C, preferably from 55 to 75 ° C; in step (2), At the T2 temperature, the mixture after the first contact is followed by the acid, and the T2 is a value between 20 to 50 ° C, and in step (3), the second contact is followed by the T3 temperature. The resulting mixture was subjected to a third contact with an acid, T3 is a value between 25 to 50 ° C, between 25 to 45 ° C. The T1-T2 (the difference in T1 and T2) is 20 to 30 ° C, T1-T3 (T1 and T3) is 20 to 30 ° C. The temperature of the reactor can be controlled by heating and / or cooling, and the temperature of the reactor is controlled by heating and / or cooled, and the temperature of each step reactor is respectively controlled at T1, T2 and T3. The deviation of the fluctuation of T1, T2 and T3 does not exceed 10 ° C.

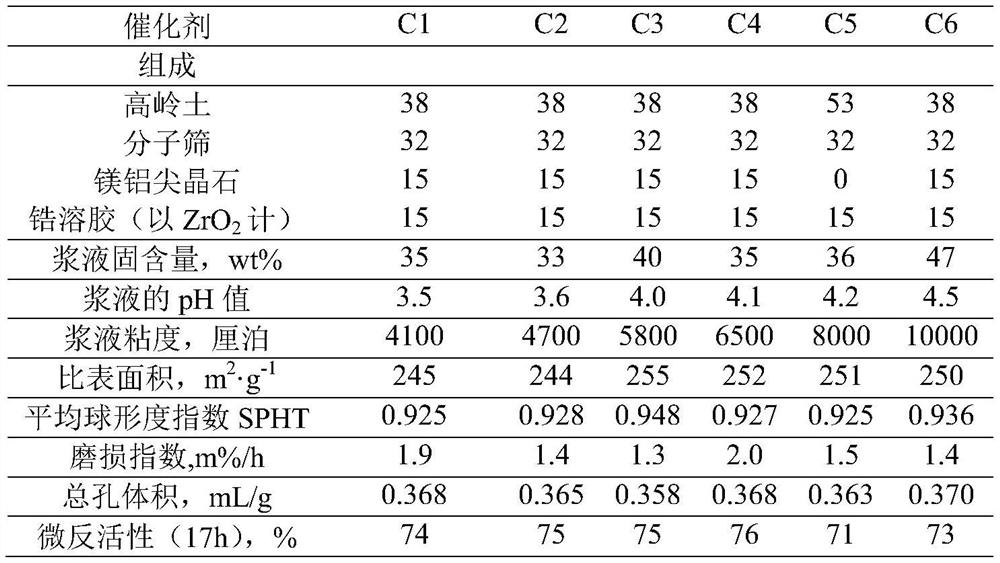

[0056]A method of preparing an FCC catalyst (catalytic cracking cat...

Embodiment 1

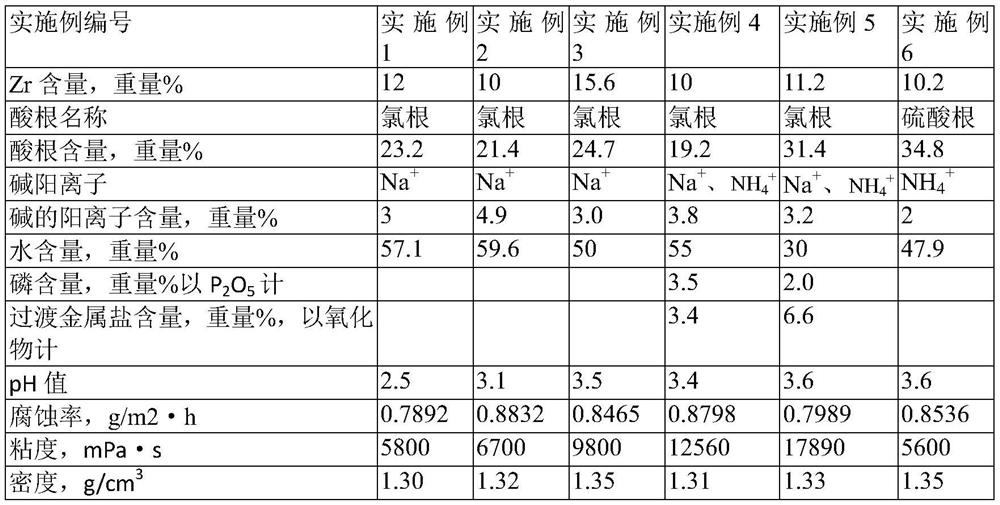

[0092]Add ZroCl in the reactor2· 8h2O 35.38kg, subsequently adding a concentration of 45% by weight of sodium hydroxide solution at a temperature of 60 ° C, a concentration of 45% by weight of sodium hydroxide solution was added, and then stirred at 60 ° C at a temperature of 60 min, after the reaction was obtained. The first contact, then at a temperature of 40 ° C according to Zr: h+The ratio of 1: 1.5 was added to 19.41 kg of hydrochloric acid having a concentration of 31% by weight, and then stirred at a temperature of 40 ° C for 60 min to obtain a second contact, and then at a temperature of 40 ° C according to Zr: h.+The ratio of 1: 1.5 was added to the second contact 19.41 kg of hydrochloric acid at a concentration of 31 wt% (WT%), and stirred at a temperature of 40 ° C for 60 min to obtain a zirconium sol. The preparation conditions and ratios are shown in Table 1, and the zirconium solution obtained is shown in Table 2.

Embodiment 2

[0094]Referring to the preparation method of Example 1, ZroCl is added to the reactor2· 8h2O, then the concentration of 45 wt% of sodium hydroxide solution was added, stirred, then the concentration of 31 wt% hydrochloric acid was added, stirred, and then the concentration of 31 wt% hydrochloric acid was added, stirred, and zirconium sol. The preparation conditions and ratios are shown in Table 1, and the zirconium solution obtained is shown in Table 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com