Maintenance and installation tool for nuclear-grade regulating valve base

A technology for installing tools and regulating valves, which is used in manufacturing tools, grinding/polishing safety devices, seat surface grinders, etc., and can solve the problems of valve seat sealing ring leakage, poor flow regulation accuracy of regulating valve, and damage to the valve seat, etc. Achieve the effect of solving disassembly and fastening problems, reducing radiation dose and high work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

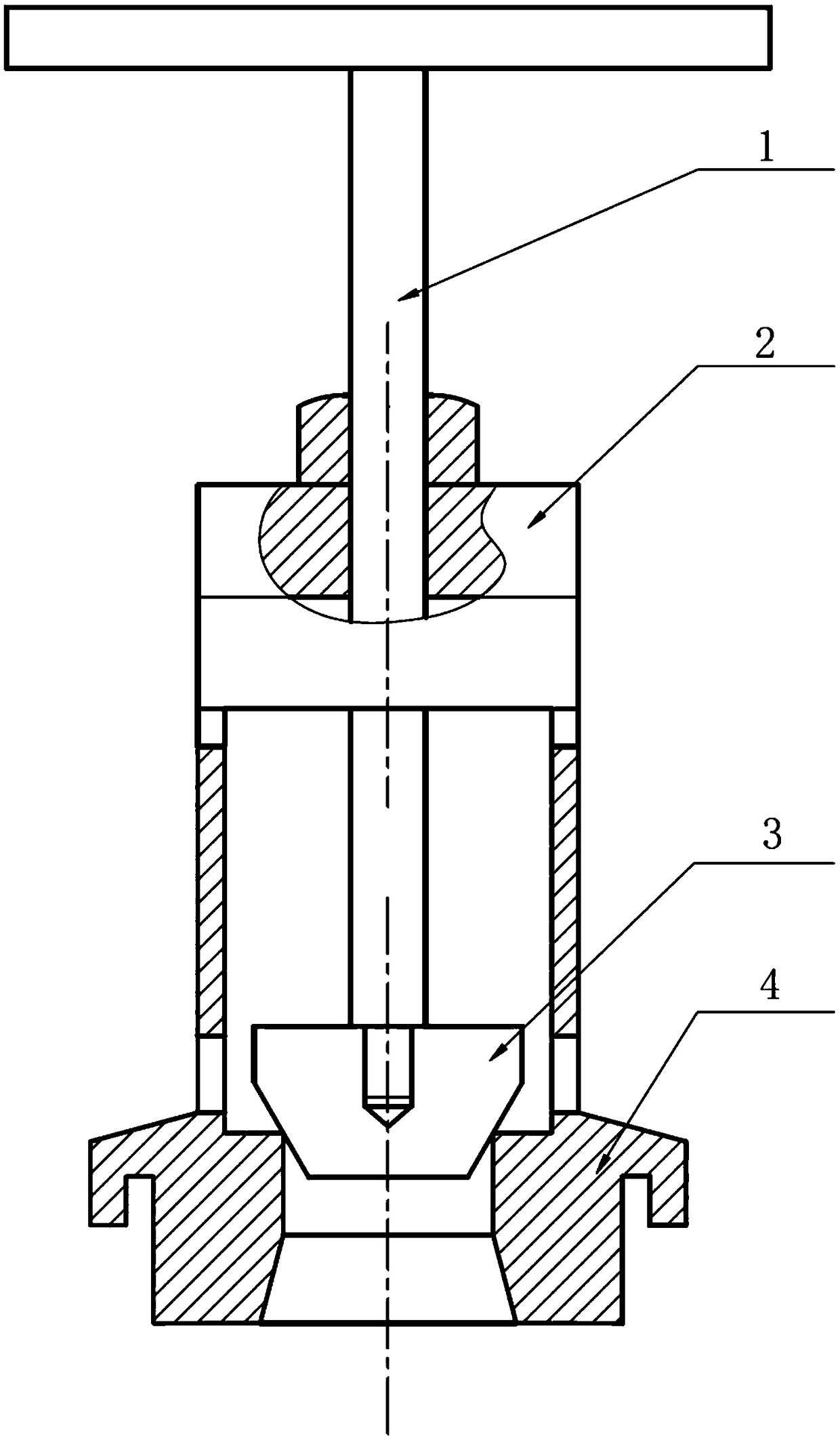

[0020] The following is a further detailed description of a valve seat maintenance and installation tool for a nuclear-level regulating valve provided by the present invention in conjunction with the accompanying drawings and specific embodiments.

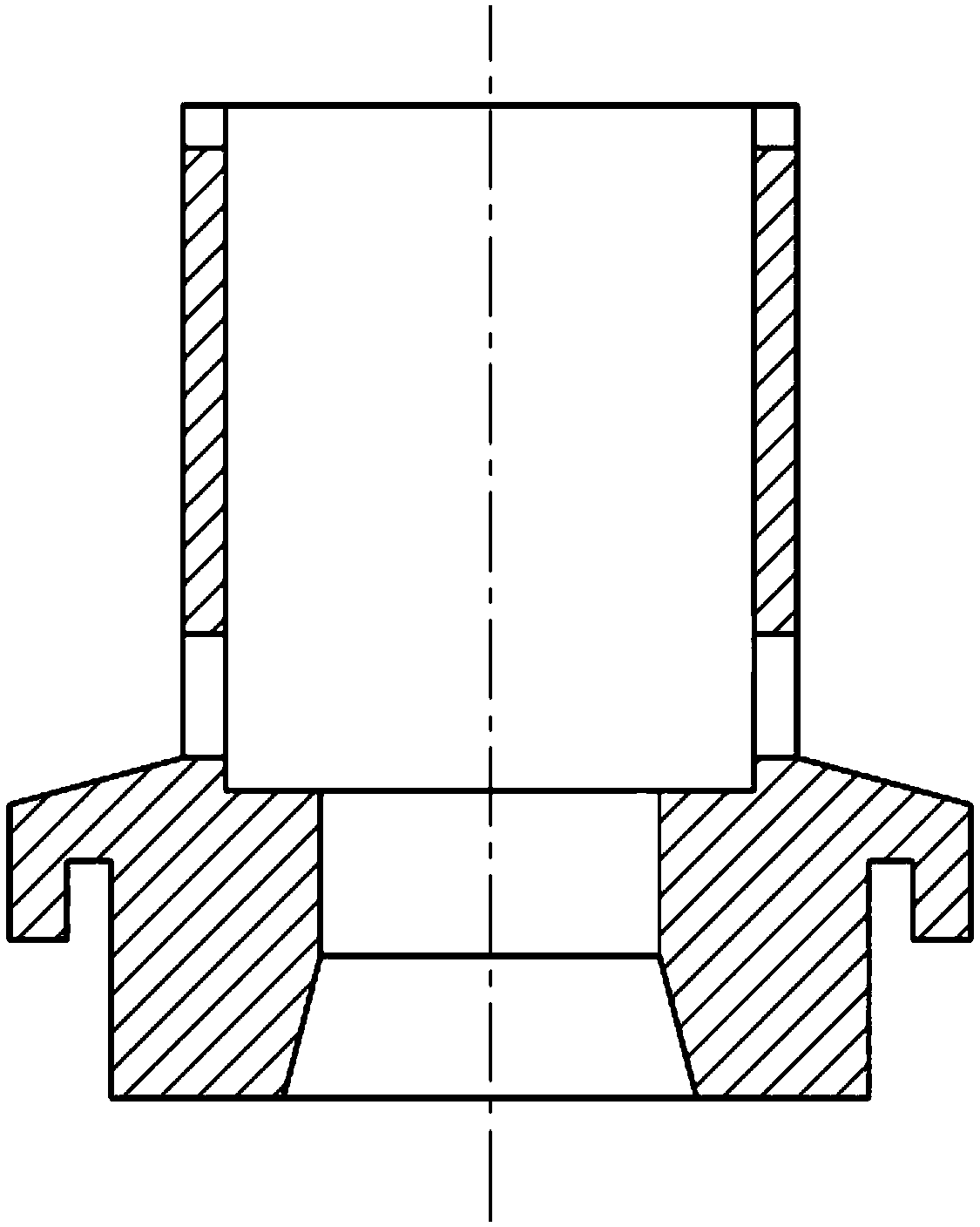

[0021] Such as figure 2 As shown, the present invention provides a kind of maintenance and installation tool for the valve seat of a nuclear-grade control valve, including a grinding rod 1, a fastening positioning nut 2, and a grinding head 3; the grinding head 3 is located in the inner cavity of the valve seat 4, and the grinding The rod 1 passes through the center hole of the fastening positioning nut 2 and is threadedly connected with the grinding head 3 .

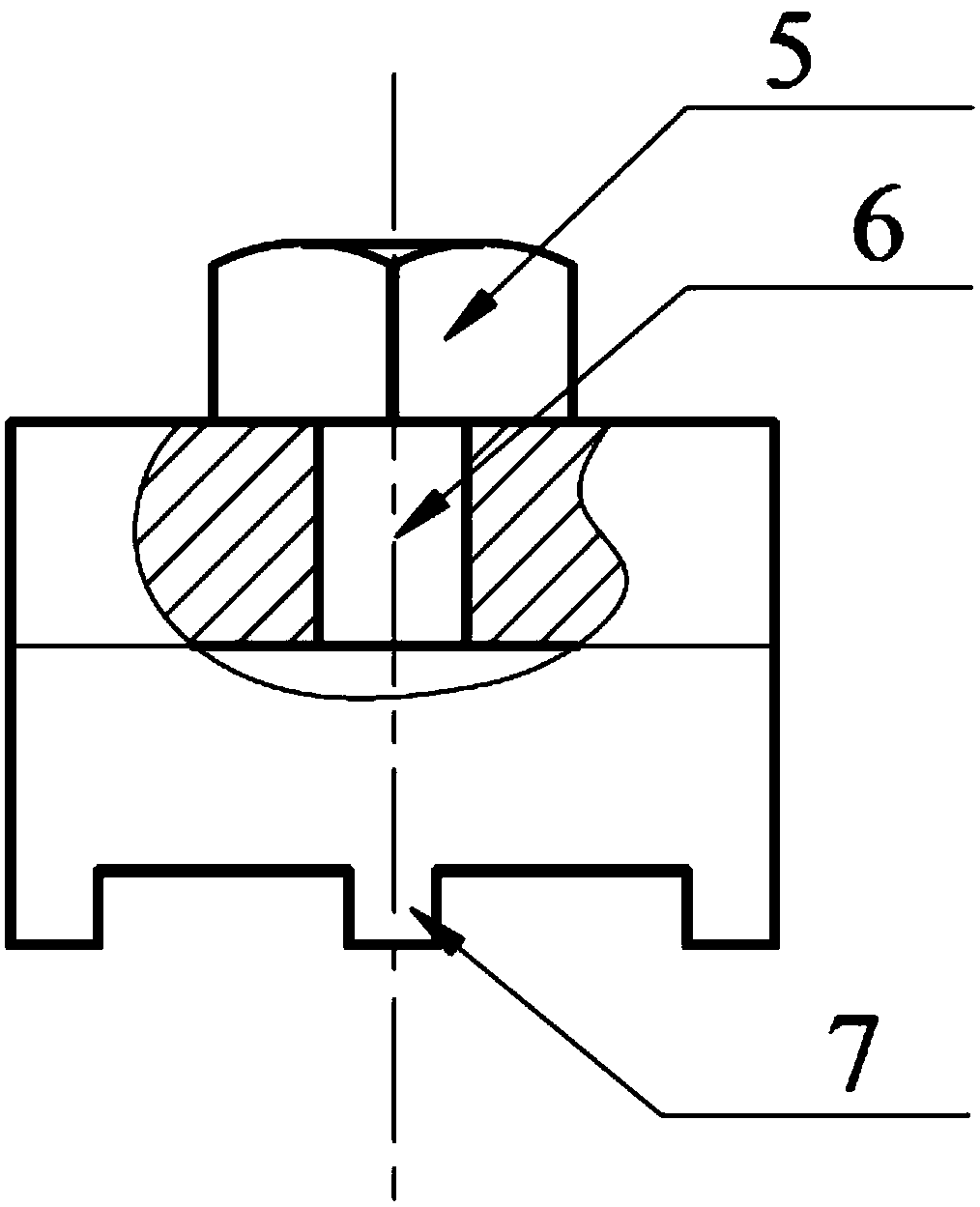

[0022] Fastening positioning nut 2 comprises fastening positioning nut hexagonal head 5, fastening positioning nut guide hole 6, fastening positioning nut claw 7; fastening positioning nut hexagonal head 5 is fixedly installed on the top of fastening positioning nut claw 7,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com