A kind of recovery method of metal lead and zinc

A recycling method, metal lead technology, applied in the direction of metal processing equipment, manufacturing tools, process efficiency improvement, etc., can solve the problems of high friction between the plate and the blade, waste of lead and zinc on the surface, easy wear and damage of the blade, etc., to improve protection High performance, high efficiency, stable cutting effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] In order to make it easy to understand the technical means, creative features, goals and effects achieved by the present invention, the present invention will be further explained in conjunction with specific implementations below.

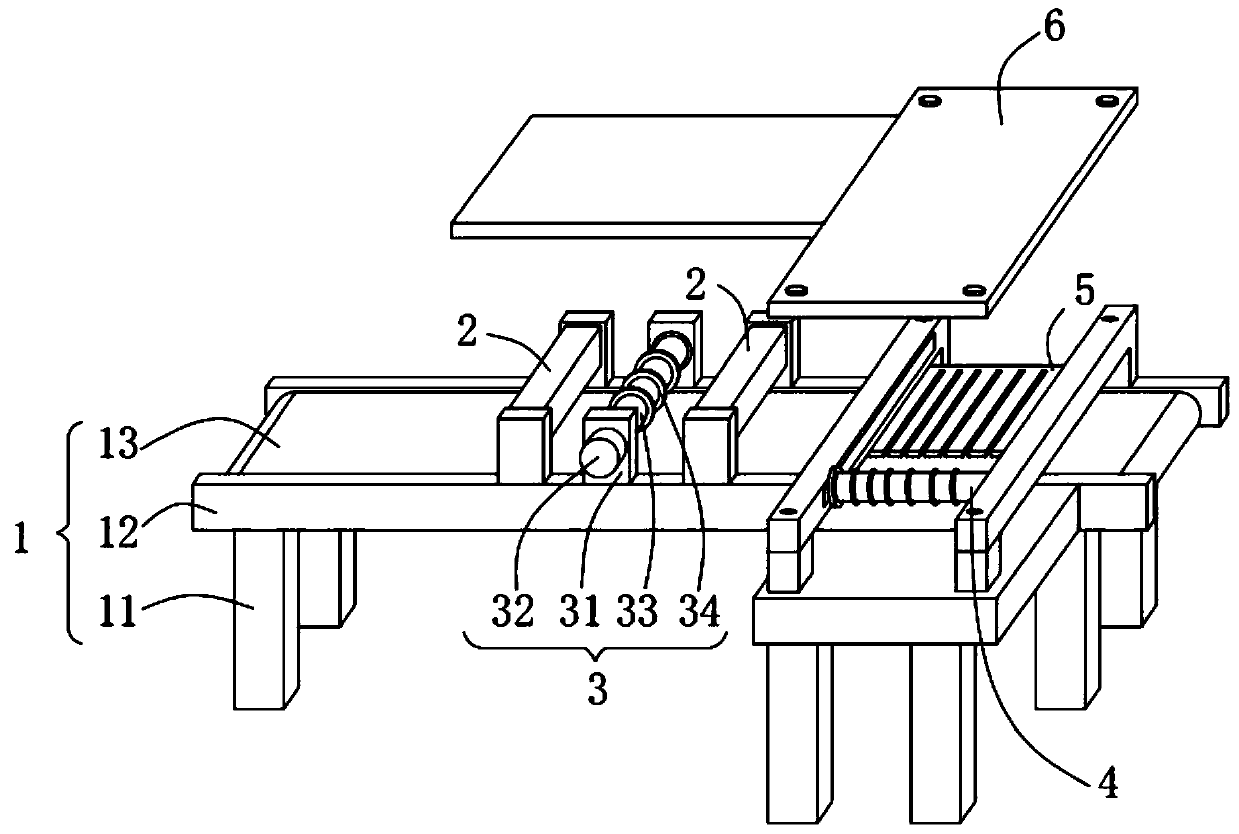

[0028] Such as Figure 1-Figure 4 As shown, a metal lead and zinc recovery method according to the present invention includes the following steps:

[0029] S1: Use a water gun to clean the metal plate, and the cleaning water uses hot water at 100 degrees Celsius;

[0030] After S2 and S1 are completed, immediately transport the cleaned metal plate to the cutting equipment to cut the plate, and the processed metal plate is divided into small pieces to facilitate subsequent smelting;

[0031] S3: Put the metal plate cut into small pieces in S2 into a smelting furnace for smelting and recycling;

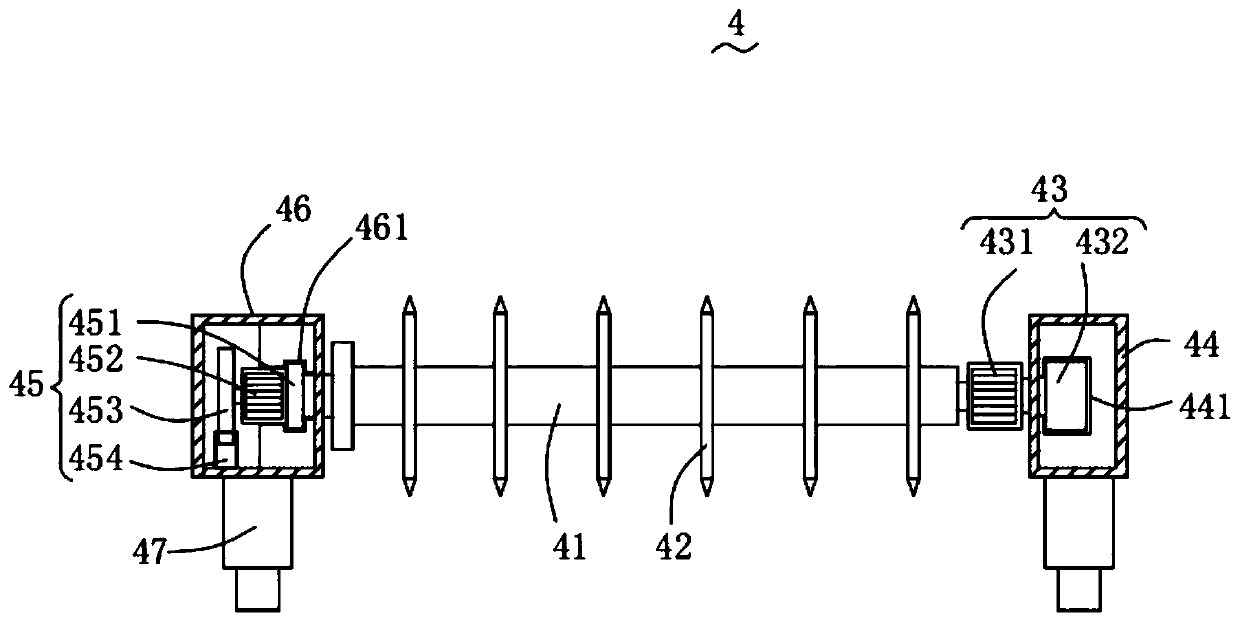

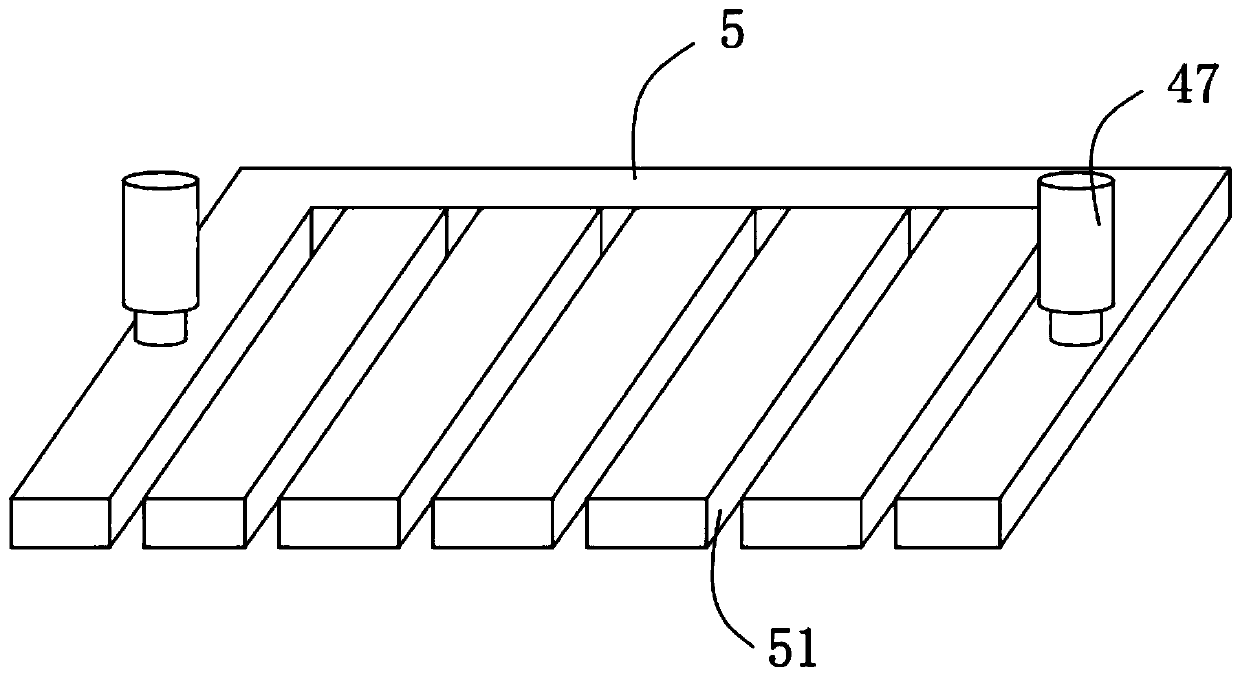

[0032] The cutting equipment used in this method includes a supporting mechanism 1, a lubricating mechanism 2, a first cutting mechanism 3, a second cutting ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com