Processing method for low-allergenic soybean powder

A processing method and low-sensitization technology, applied in milk substitutes, dairy products, applications, etc., can solve the problems of reducing the efficiency of immune reactivity, reducing IgE binding ability, reducing soybean allergens, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

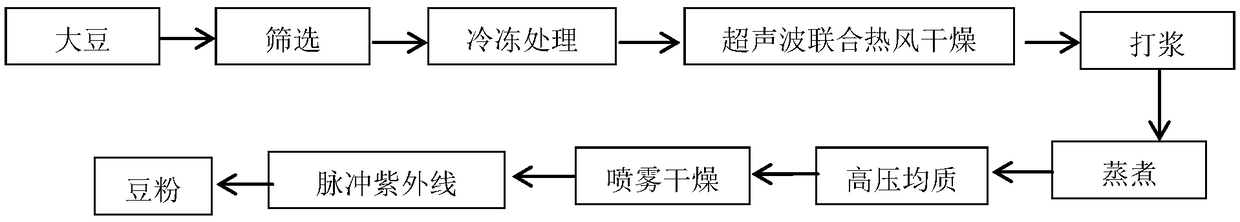

Image

Examples

Embodiment 1

[0016] (1) Soak the screened soybeans at a low temperature of 4°C for 14 hours at a material-to-liquid ratio of 1:3, and dry the soaked soybeans with gauze and put them in a vacuum freezer at -15°C for 3 days; (2) Spread frozen soybeans on gauze and place them in an ultrasonic hot air dryer to dry and dehydrate, set the ultrasonic frequency to 20.00kHz, ultrasonic power to 70W, ultrasonic distance to 20cm, and dry at a temperature of 105°C for 30s; (3) press The ratio of solid to liquid is 1:3, beat for 9 minutes, pass through a 100-mesh filter, and cook the obtained raw soybean milk in a cooking pot for 5 minutes, then add alkaline protease to hydrolyze it for 20 minutes to remove the allergenic factor 7S soybean in soybean For globulin, adjust the pH to 9.0, heat to inactivate the enzyme; (4) Pump the soybean milk into the homogenizer once for homogenization, the homogenization pressure is 30MPa, and then spray dry, the air inlet temperature is 185°C, and the outlet air tempe...

Embodiment 2

[0018] (1) Soak the screened soybeans at a low temperature of 4°C for 12 hours at a material-to-liquid ratio of 1:3, and dry the soaked soybeans with gauze and put them in a vacuum freezer at -10°C for 2 days; (2) Spread frozen soybeans on gauze and place them in an ultrasonic hot air dryer to dry and dehydrate, set the ultrasonic frequency to 19.00kHz, ultrasonic power to 50W, ultrasonic distance to 15cm, and dry at a temperature of 100°C for 25s; (3) press The ratio of solid to liquid is 1:3, beat for 9 minutes, pass through a 100-mesh filter, and cook the obtained raw soybean milk in a cooking pot for 5 minutes, then add alkaline protease to hydrolyze it for 20 minutes to remove the allergenic factor 7S soybean in soybean For globulin, adjust the pH to 9.0, heat to inactivate the enzyme; (4) Pump the soybean milk into the homogenizer once for homogenization, the homogenization pressure is 30MPa, and then spray dry, the air inlet temperature is 185°C, and the outlet air tempe...

Embodiment 3

[0020] (1) Soak the screened soybeans at a low temperature of 4°C for 16 hours at a material-to-liquid ratio of 1:3, and dry the soaked soybeans with gauze and put them in a vacuum freezer at -18°C for 4 days; (2) Lay frozen soybeans on gauze and place them in an ultrasonic hot air dryer to dry and dehydrate, set the ultrasonic frequency to 22.00KHz, ultrasonic power to 100W, ultrasonic distance to 30cm, and dry at a temperature of 110°C for 35s; (3) press The ratio of solid to liquid is 1:3, beat for 10 minutes, pass through a 100-mesh filter, and cook the obtained raw soybean milk in a cooking pot for 5 minutes, then add alkaline protease to hydrolyze it for 20 minutes to remove the allergenic factor 7S soybean in soybean For globulin, adjust the pH to 9.0, heat to inactivate the enzyme; (4) Pump the soybean milk into the homogenizer once for homogenization, the homogenization pressure is 30MPa, and then spray dry, the air inlet temperature is 185°C, and the outlet air temper...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com