A linear motor

A technology of linear motors and conductive parts, applied in the direction of circuits, current collectors, electrical components, etc., can solve problems such as fatigue damage of power lines, and achieve the effect of avoiding fatigue damage and occupying a small space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

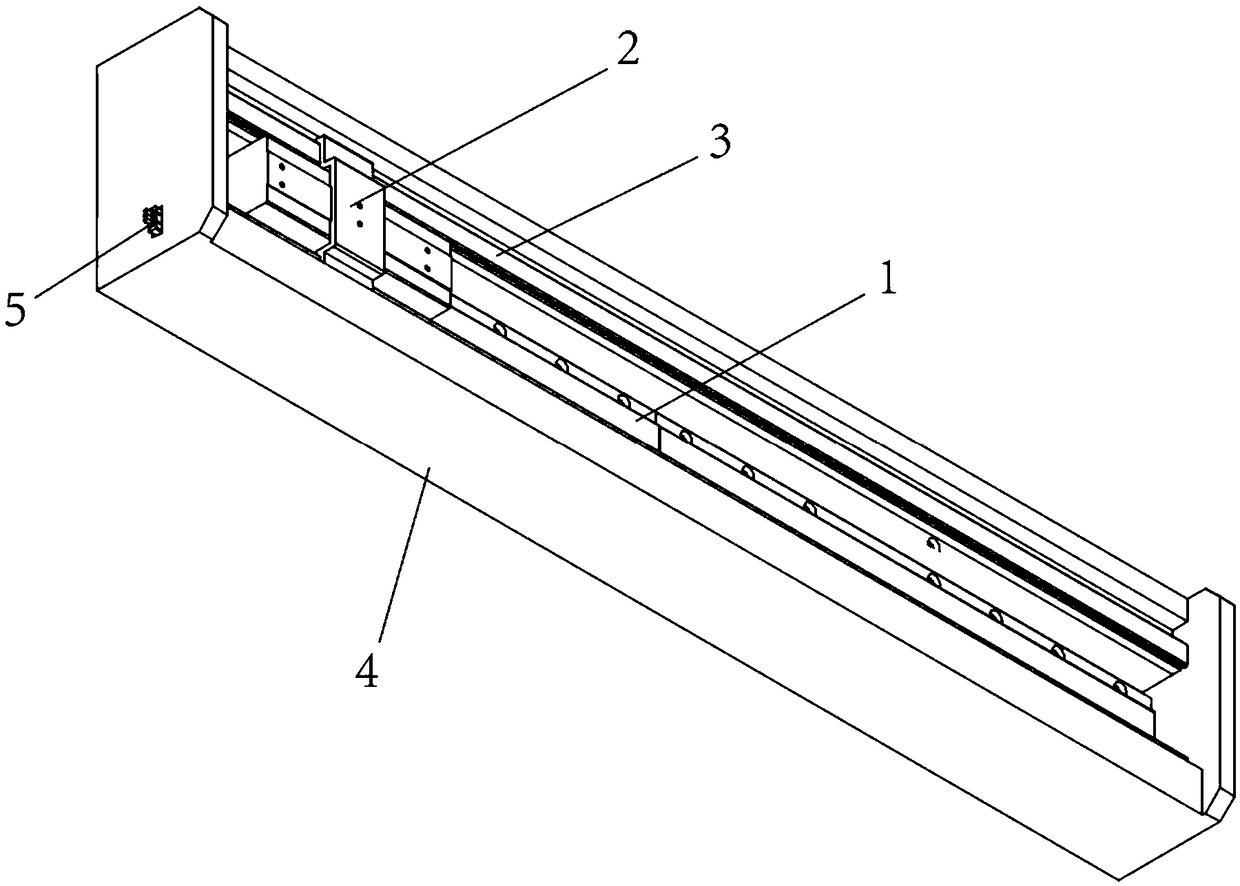

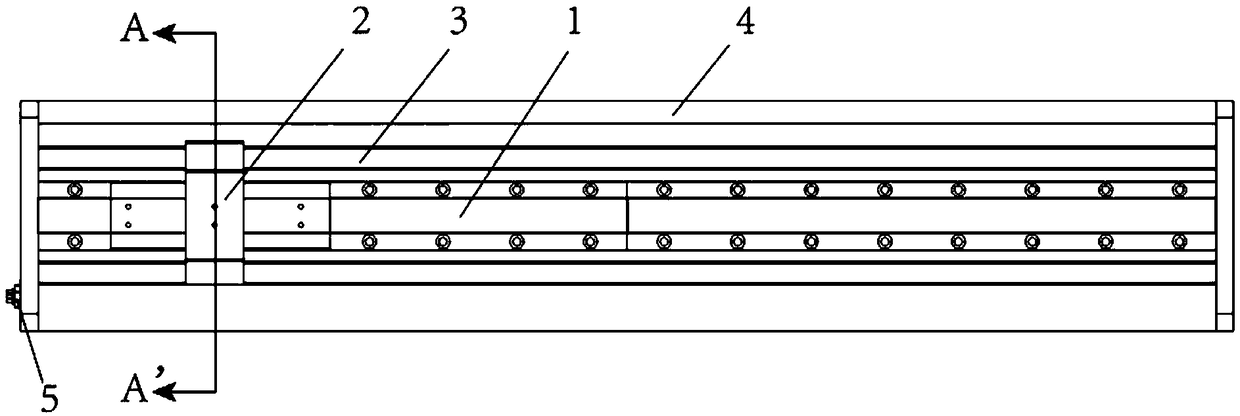

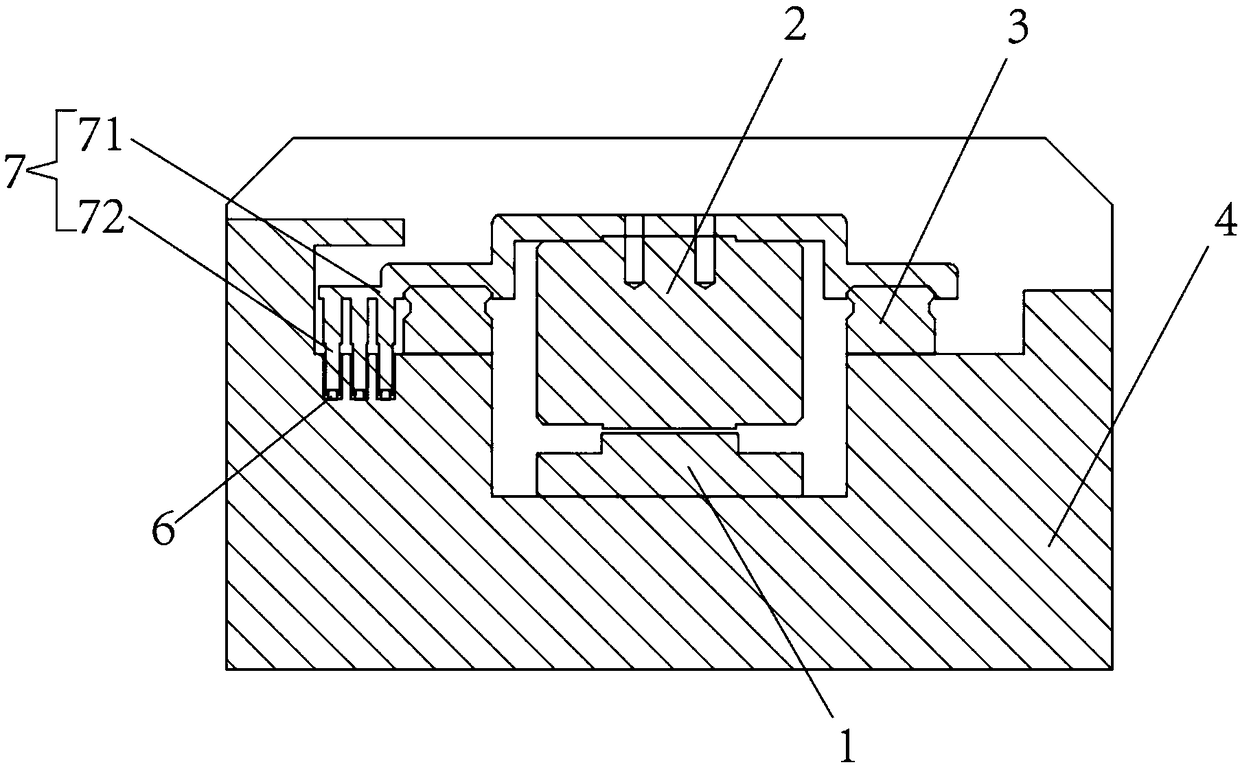

[0029] Example 1, please refer to Figure 1-Figure 6 As shown, this embodiment provides a linear motor, including: a stator magnetic plate 1, a mover 2 and a power supply slide rail, the mover 2 is arranged above the stator magnetic plate 1, and there is a gap between the mover 2 and the stator magnetic plate 1 , the power supply slide rail is parallel to the moving direction of the mover 2, the mover 2 is provided with a conductive component 7, and the conductive component 7 abuts against the power supply slide rail.

[0030] In the linear motor provided in this embodiment, the mover 2 is located above the stator magnetic plate 1 and has a certain distance from the stator magnetic plate 1 . During operation, the mover 2 can move along the length direction of the stator magnetic plate 1 . The power supply slide rail is parallel to the moving direction of the mover 2, and is connected to an external power source, that is, the power line is connected to the power supply slide r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com