A lead frame tape cutting mechanism

A lead frame and tape cutting technology, applied in the direction of electrical components, semiconductor/solid-state device manufacturing, circuits, etc., can solve the problems of semiconductor device vibration and drop, unfavorable semiconductor device collection, etc., and achieve the effect of convenient operation and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The following is further described in detail through specific implementation methods:

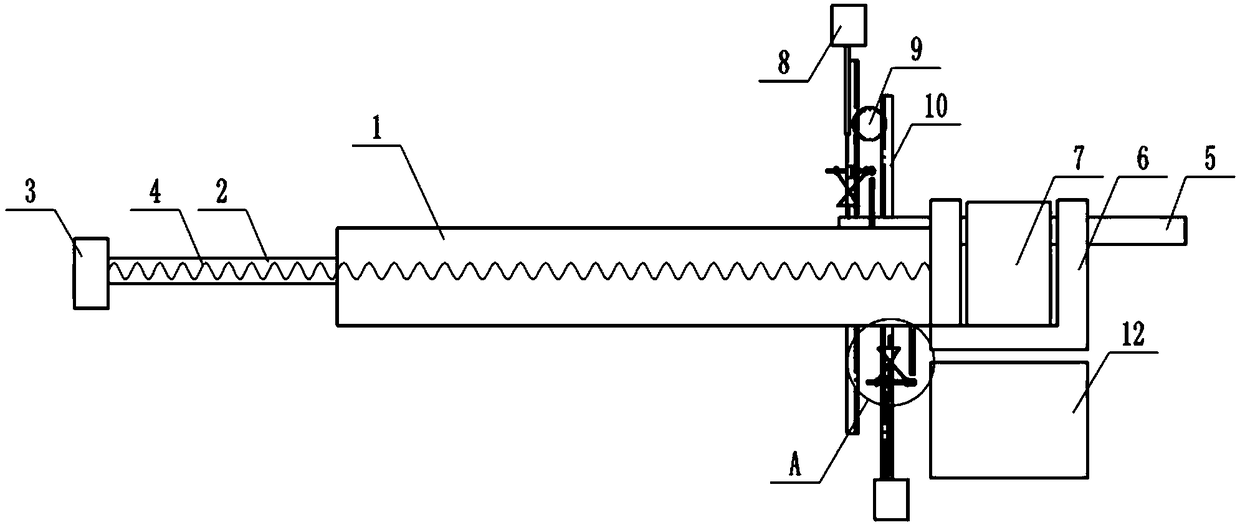

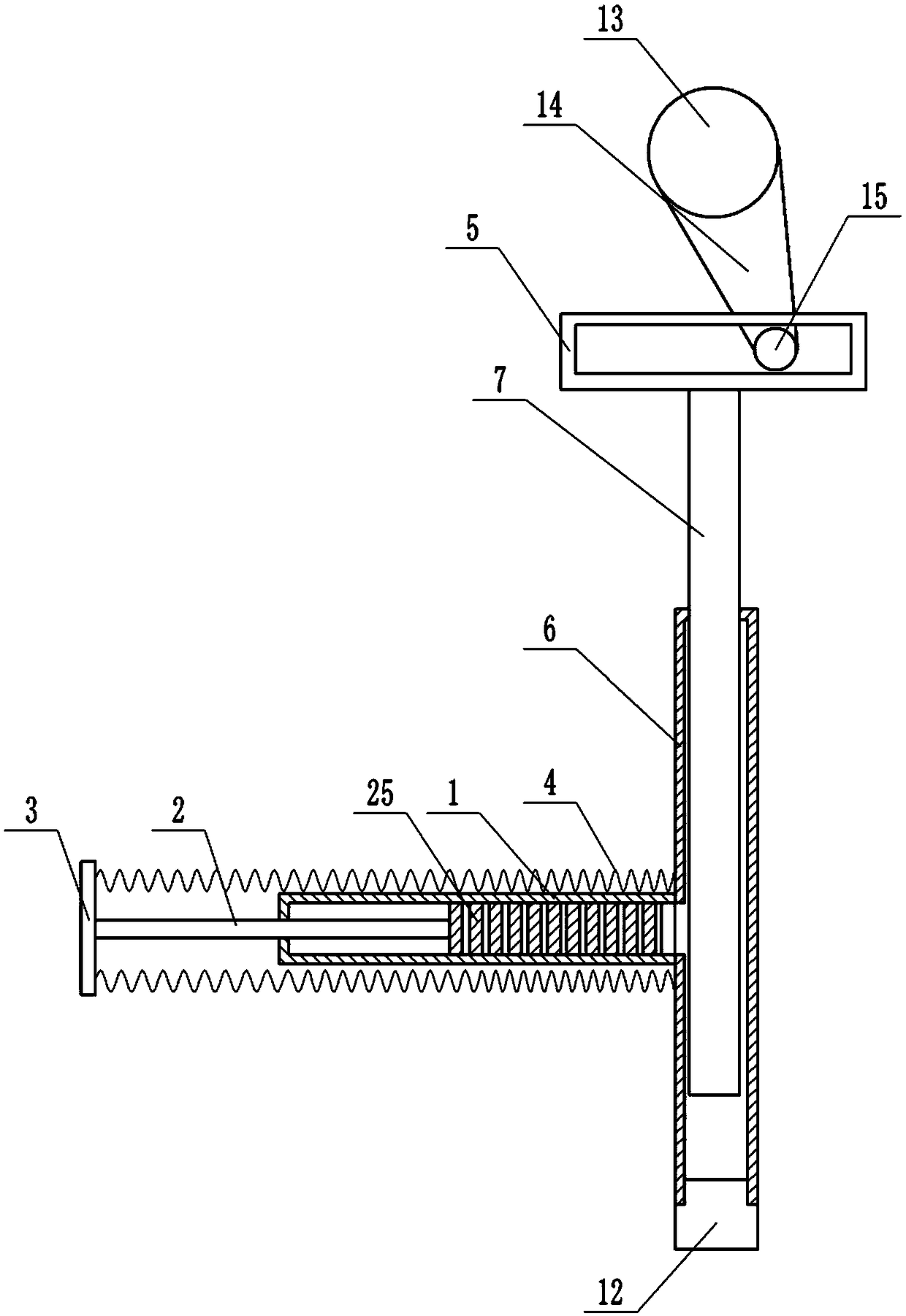

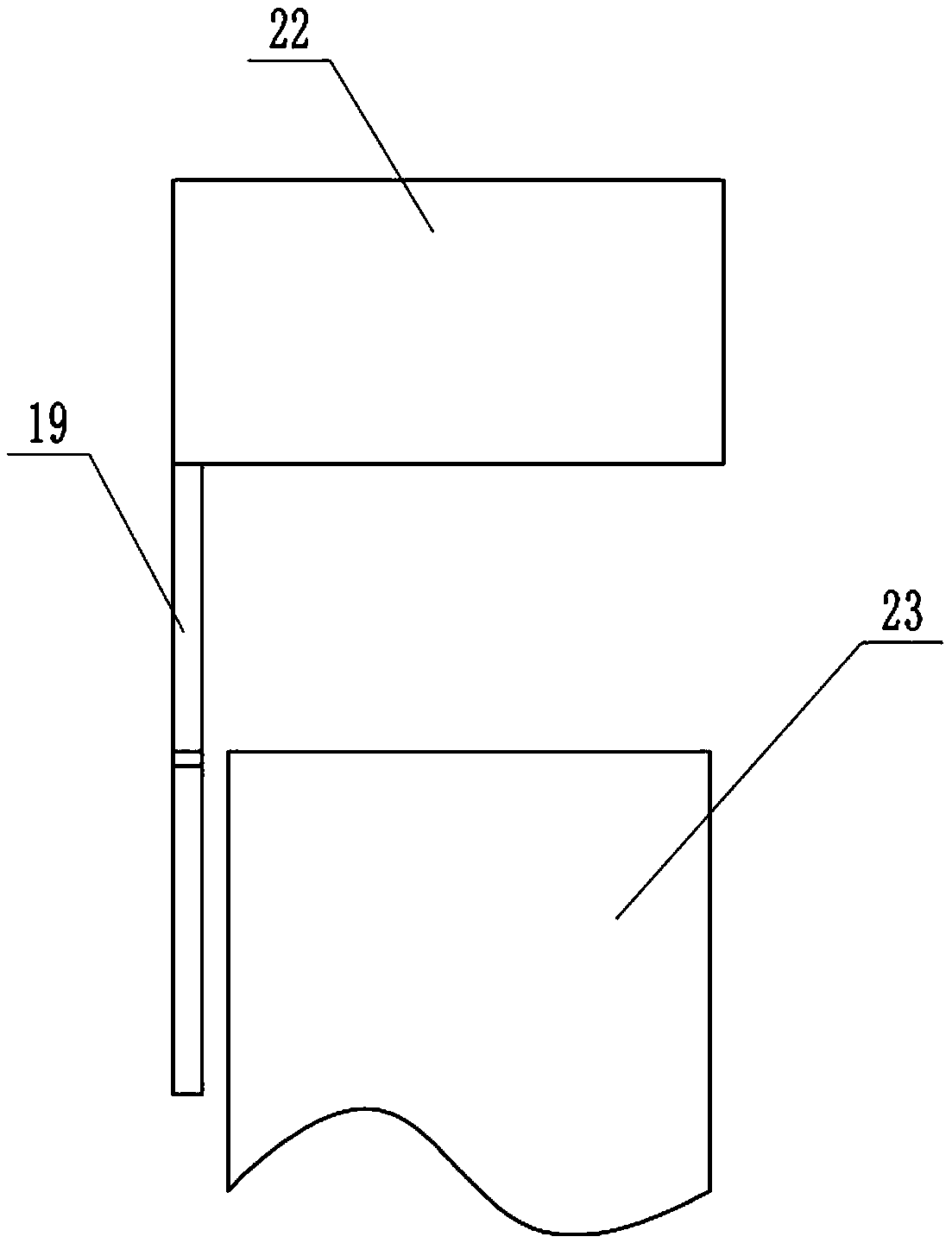

[0021] The reference signs in the accompanying drawings of the specification include: feeding cylinder 1, push rod 2, push block 3, extension spring 4, connecting frame 5, discharging cylinder 6, discharging rod 7, cylinder 8, second gear 9, tooth Bar 10, collection box 12, turntable 13, connecting rod 14, slide bar 15, leading screw 16, moving block 17, clamping sleeve 18, pull open bar 19, riser 20, first gear 21, pull open piece 22, Heat cutter 23, cylinder rod 24, semiconductor device 25, lead frame band 26.

[0022] The embodiment is basically as attached Figure 1-Figure 6 Shown: a lead frame tape cutting mechanism, including a frame, the frame is provided with a horizontally arranged feeding cylinder 1, and the right end of the feeding cylinder 1 is connected with a discharge cylinder 6 perpendicular to the feeding cylinder 1 and arranged horizontally , the left end of the f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com