Centrifugal wind wheel with flow guide device

A technology of flow guiding device and centrifugal wind wheel, which is applied to components of pumping devices for elastic fluids, non-variable pumps, machines/engines, etc., and can solve problems such as unresolved airflow and increasing the working area of blades , to achieve the effect of smooth airflow, reducing eddy current and reducing eddy current separation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

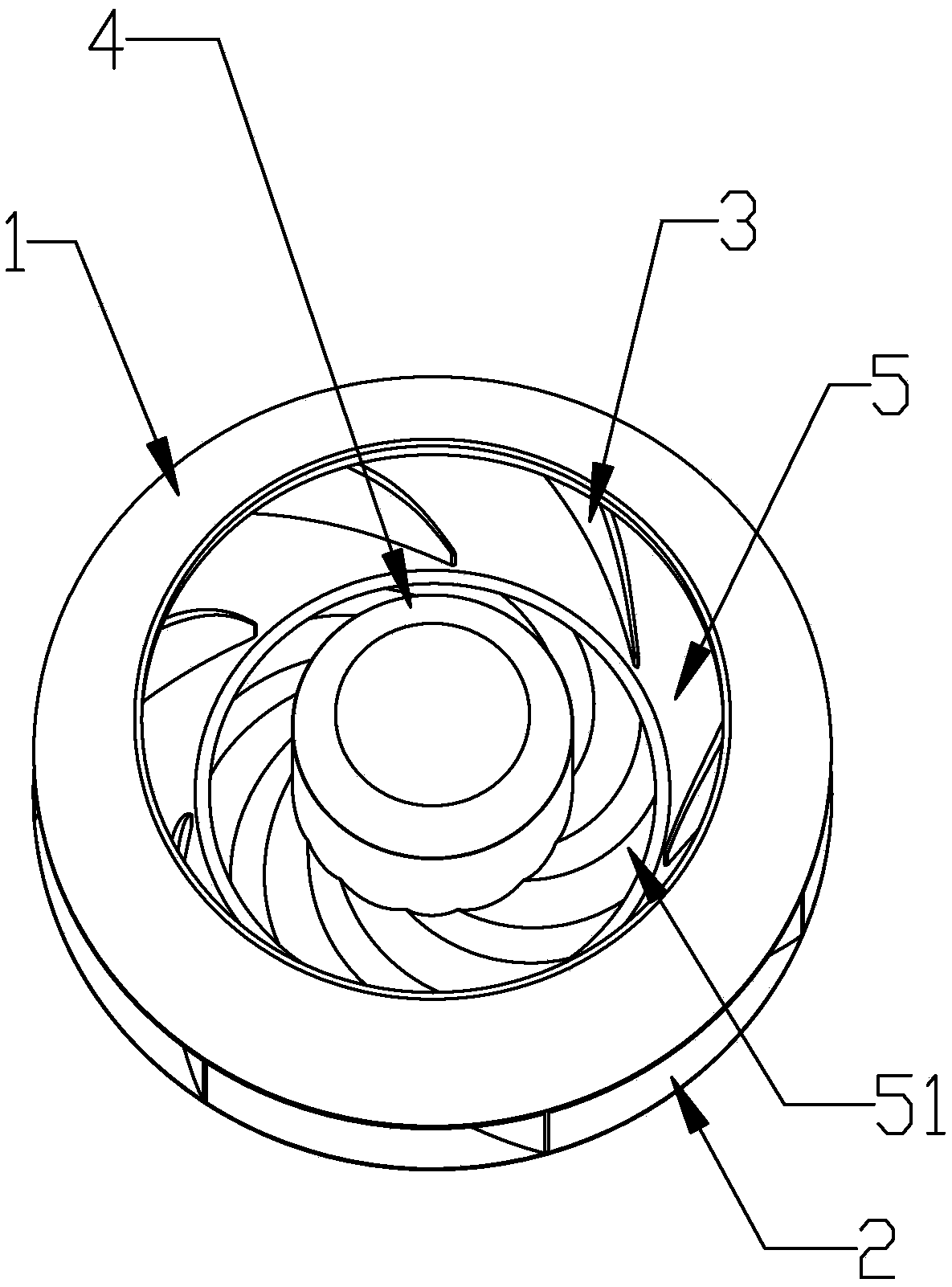

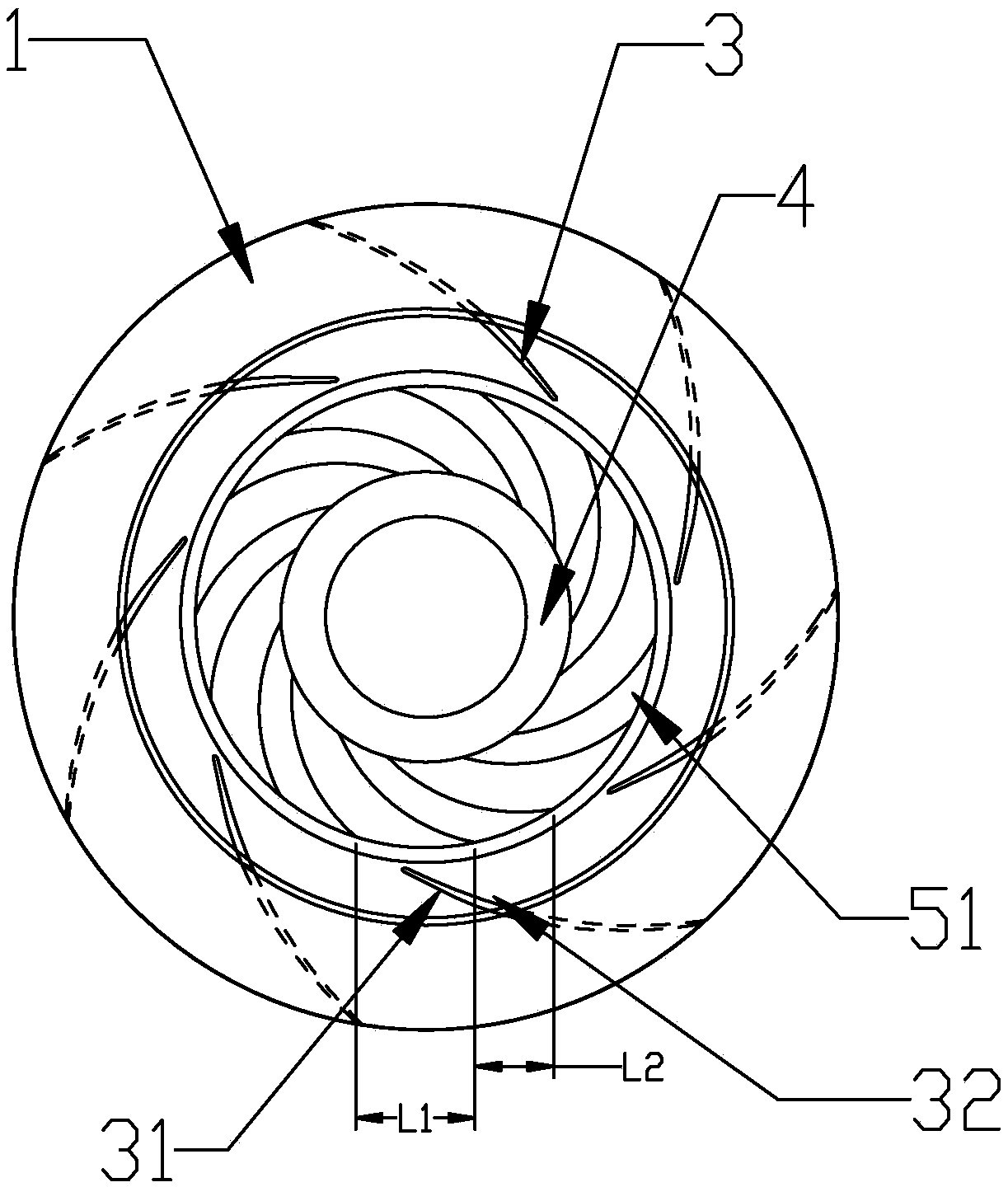

[0036] like figure 1 As shown, a centrifugal wind rotor with deflector 5 includes a front disc 1 of the rotor, a rear disc 2 of the rotor, a motor mounting part 4, and rotor blades 3, and the rotor blades 3 are arranged obliquely or vertically on the Between the front disk 1 of the wind rotor and the rear disk 2 of the wind rotor, and the upper and lower ends of the blades 3 of the wind rotor are respectively connected with the front disk 1 of the wind rotor and the rear disk 2 of the wind rotor. The motor installation part 4 is arranged at the center of the wind rotor rear panel 2, and the motor installation part 4 is used for connecting with the bottom of the motor. The centrifugal wind rotor also includes a deflector 5, which is arranged on the rear plate 2 of the wind rotor and placed between the motor mounting part 4 and the blades 3 of the wind rotor. The deflector 5 It can be integrally formed with the rear disk 2 of the wind rotor or installed on the rear disk 2 of th...

Embodiment 2

[0044] like Figure 5 As shown, this embodiment only describes the difference from the above embodiment, and the rest of the technical features are the same as the above embodiment. In this embodiment, the number of the guide channels 51 is consistent with the number of the wind rotor blades 3 , that is, each blade channel of the rotor blade 3 corresponds to one guide channel 51 . It is ensured that when the wind rotor rotates, the airflow of the wind rotor rear disk 2 will flow into the blade flow channels of the wind rotor blades 3 along the flow guide flow channel 51 of the flow guide device 5 .

Embodiment 3

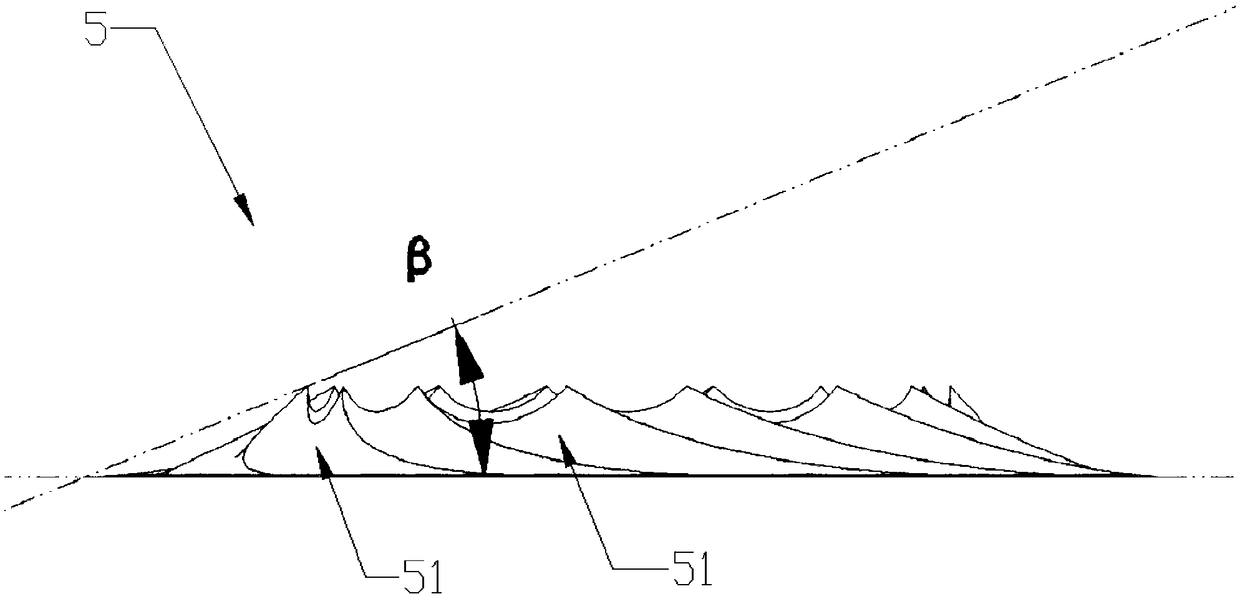

[0046] like Image 6 As shown, this embodiment only describes the difference from the above embodiment, and the rest of the technical features are the same as the above embodiment. The end of each diversion flow channel 51 adjacent to the motor mounting part 4 is the initial end 511 of the flow channel, and the circumferential profile of the initial end 511 of the flow channel is a single arc or multiple arcs, so The multiple arcs include at least two arcs with different arc lengths.

[0047] In this embodiment, preferably, the profile line of the initial end 511 of each flow guide channel 51 along the circumferential direction is a double arc, and the double arc is connected with the suction surface 31 of the wind rotor blade. The radius of the arc in the similar direction is R1, and the width of the arc is A1; the radius of the arc in the direction close to the pressure surface 32 of the wind rotor blade in the double arc is R2, and the width of the arc is A2, and the doubl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com