Natural gas engine combustion organization method with precombustion chamber low-pressure air supply and in-cylinder high-pressure direct injection functions

A technology of pre-combustion chamber and natural gas, applied in gaseous engine fuel, combustion engine, internal combustion piston engine, etc., to achieve the effects of accelerating flame propagation speed, improving economy and emission, and shortening combustion time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention is described in more detail below in conjunction with accompanying drawing example:

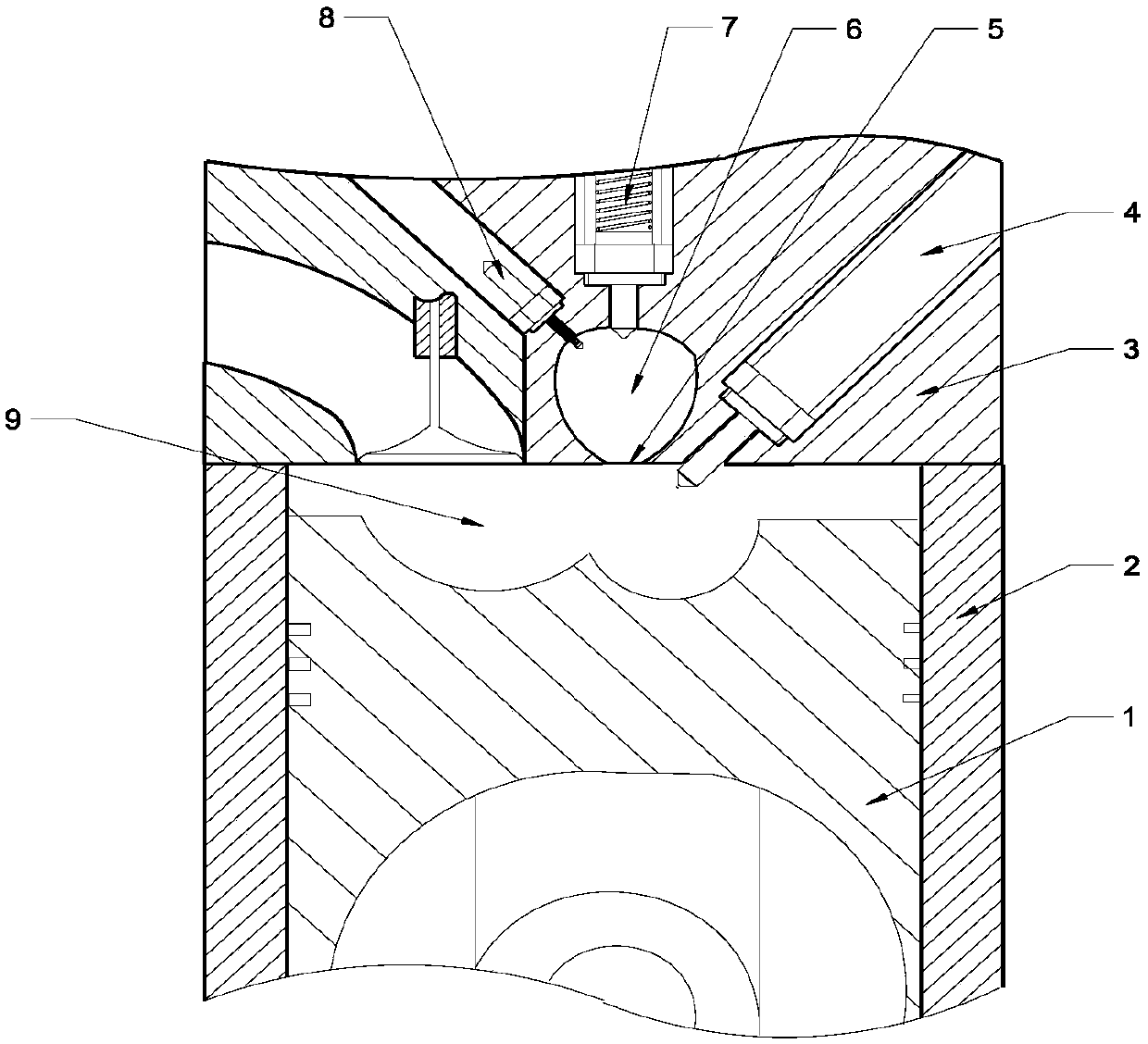

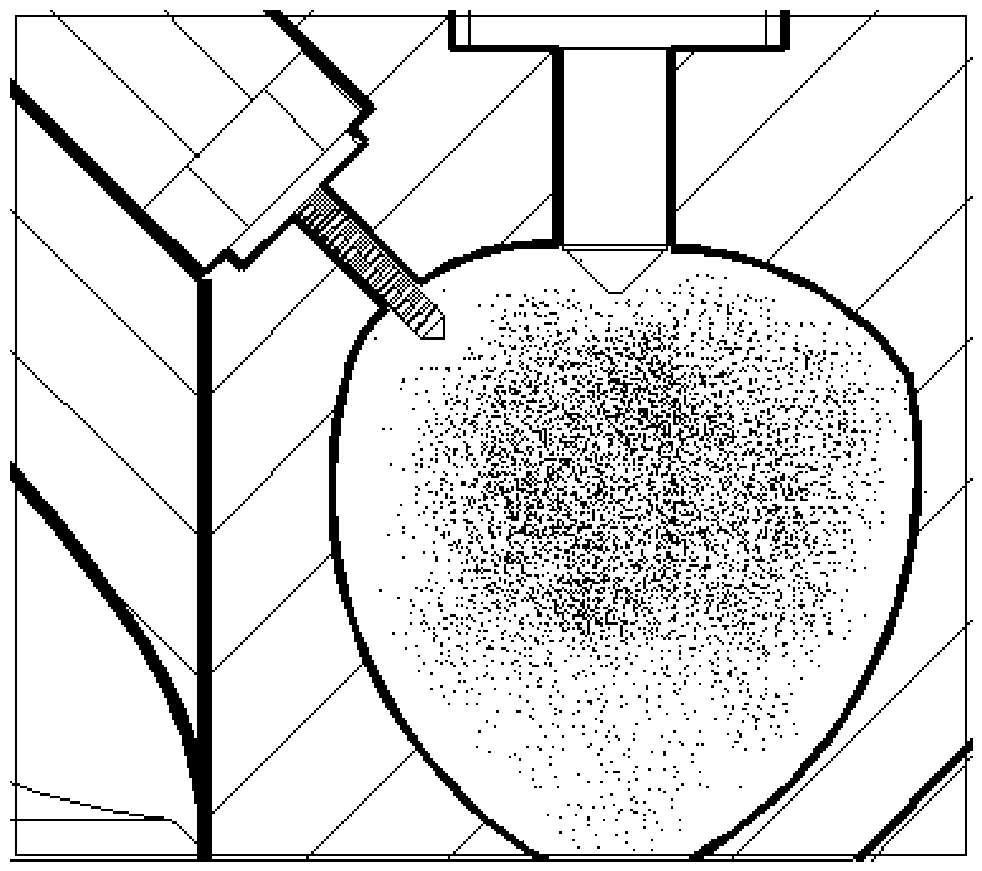

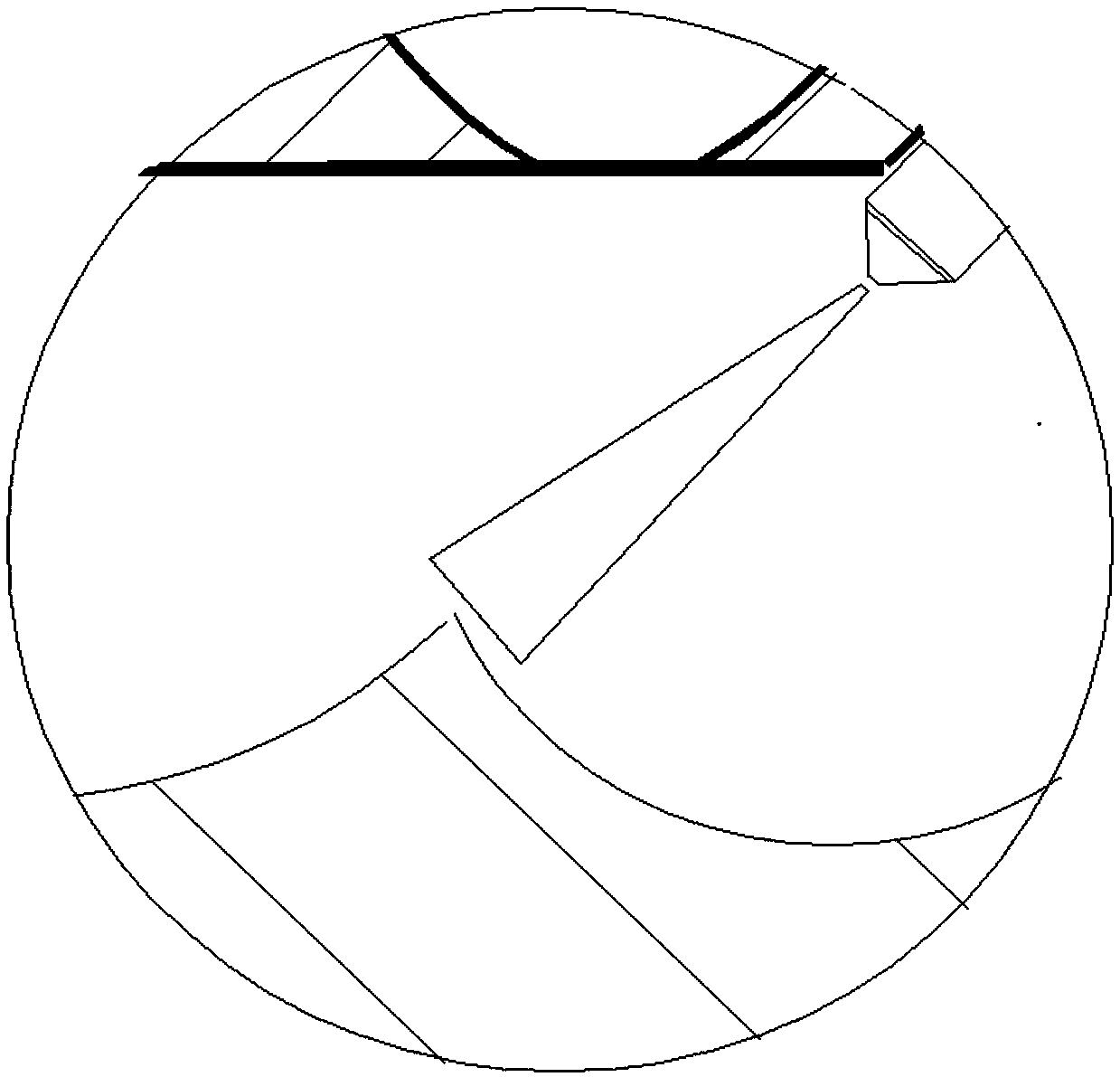

[0020] combine Figure 1-4 , the structure of the natural gas engine combustion system of the present invention includes: piston 1, cylinder liner 2, cylinder head 3, high-pressure gas injection device 4, pre-combustion chamber outlet 5, pre-combustion chamber 6, low-pressure one-way gas supply device 7, spark plug 8, main Combustion chamber9. The ω-shaped main combustion chamber is composed of the upper surface of the piston, the peripheral wall of the cylinder liner and the lower surface of the cylinder head. The lower narrow oval structure, the central axis of the pre-combustion chamber coincides with the central axis of the cylinder, the outlet of the pre-chamber is located at the center of the bottom of the pre-chamber, the diameter of the outlet is not less than 5mm, and the maximum diameter of the oval pre-chamber is equal to the diameter of the outlet of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com