Automatic control method for circuit board electroplating

An electronic circuit board, electrolyte technology, applied in the direction of electrodes, electrolysis process, electrolysis components, etc., to achieve the effect of easy operation and mastery, and reduce production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

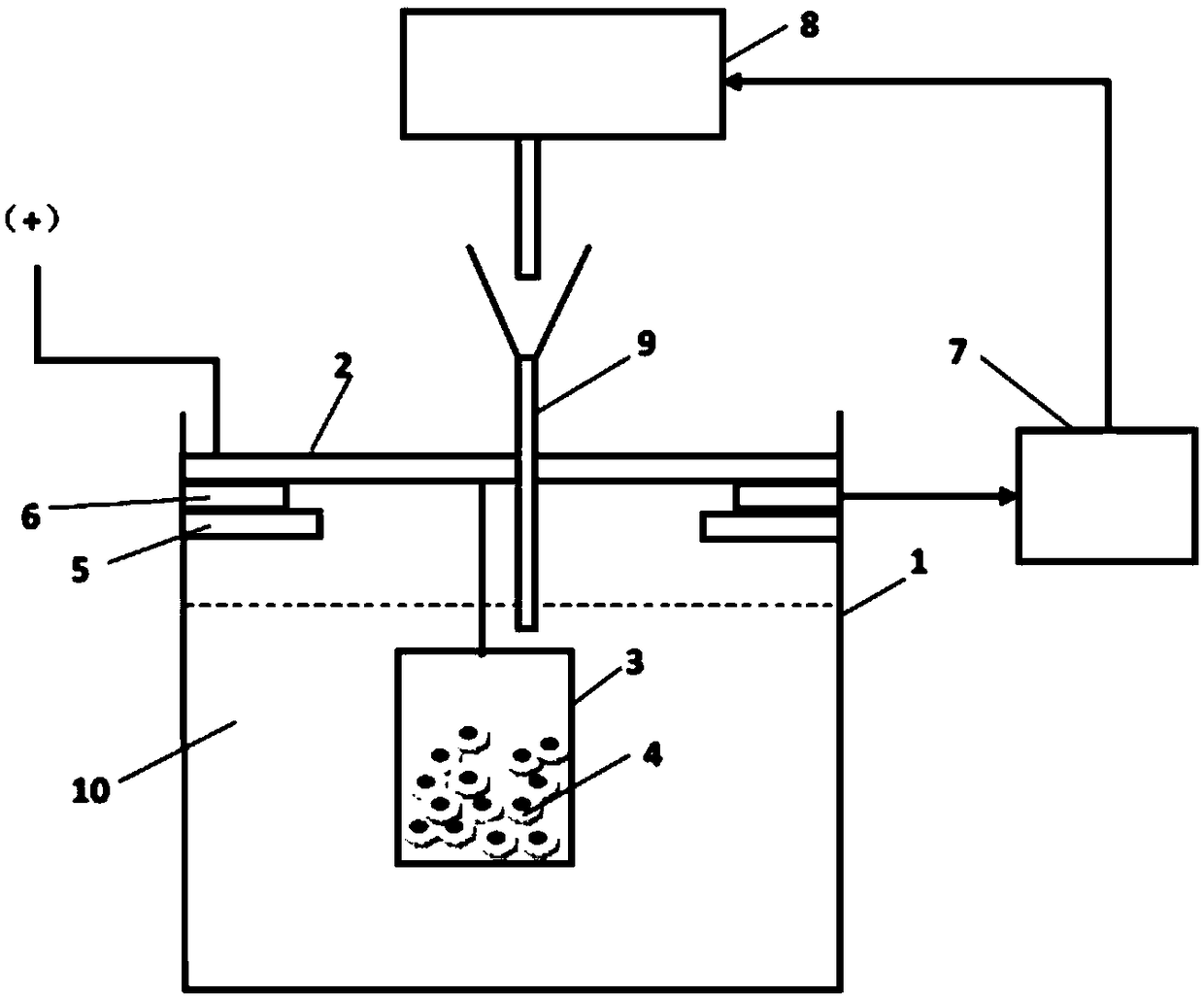

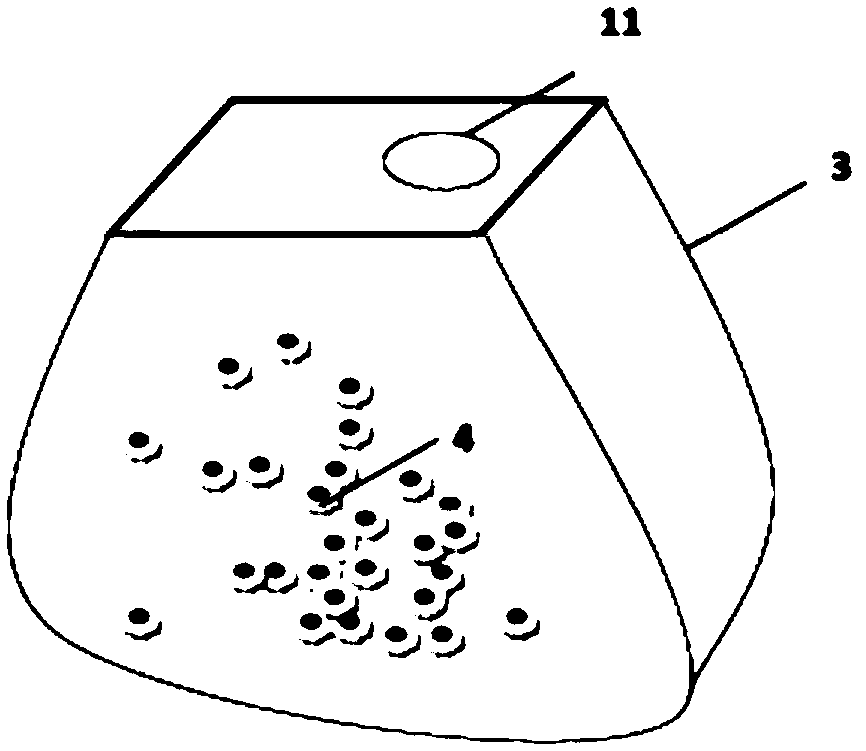

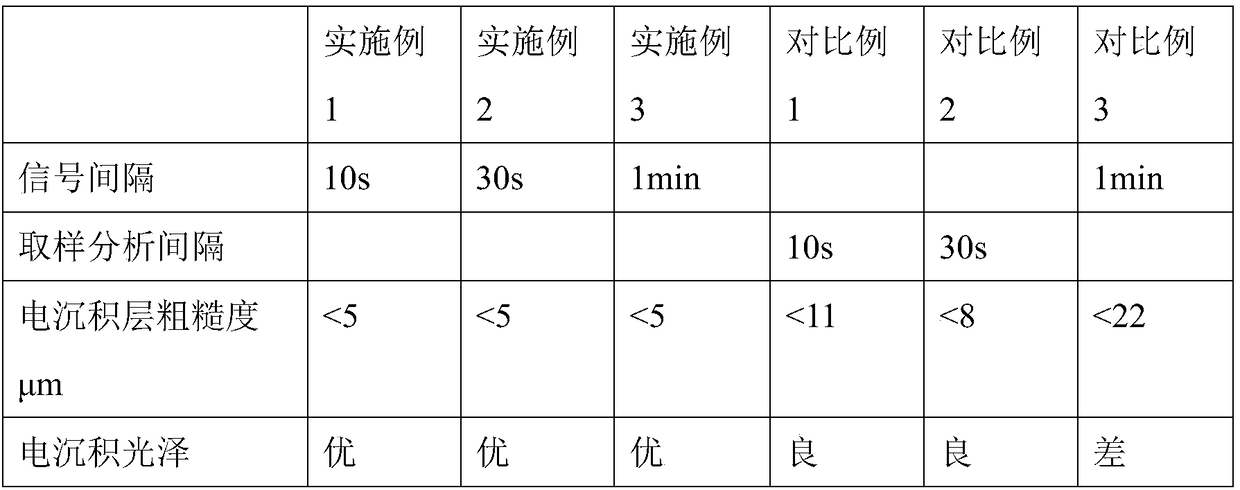

Embodiment 1

[0026] Taking copper deposition electroplating, which is common in electroplating of electronic circuit boards, as an example, the precise and automatic control method of copper ion concentration in the electrolyte during electroplating is as follows: 11. The lower end bag is in a flexible anode bag, and is suspended under the anode conductive rod. A micro-pressure detector is installed under the anode conductive rod. When the electrodeposition power supply is connected, the micro-pressure detector detects the pressure value in real time, and will start Pressure value P 0 And the subsequent pressure value Pn (n=1, 2, 3, ...) is transmitted to the signal control and analysis unit. In the production of this embodiment, the electrodeposition time is 5 minutes, and the signal analysis unit calculates that the electrodeposition has been carried out for 30s The subsequent pressure change per unit time ΔP n =Pn -P n-1 , every 10s is an interval, calculated by the signal control ana...

Embodiment 2

[0028] Taking copper deposition electroplating, which is common in electroplating of electronic circuit boards, as an example, the precise and automatic control method of copper ion concentration in the electrolyte during electroplating is as follows: 11. The lower end bag is in a flexible anode bag, and is suspended under the anode conductive rod. A micro-pressure detector is installed under the anode conductive rod. When the electrodeposition power supply is connected, the micro-pressure detector detects the pressure value in real time, and will start Pressure value P 0 And the subsequent pressure value Pn (n=1, 2, 3, ...) is transmitted to the signal control analysis unit. In the production of this embodiment, the electrodeposition time is 20 minutes, and the signal analysis unit calculates that the electrodeposition has been carried out for 1 minute The subsequent pressure change per unit time ΔP n =P n -P n-1 , every 30s is an interval, calculated by the signal control...

Embodiment 3

[0030] Taking copper deposition electroplating, which is common in electroplating of electronic circuit boards, as an example, the precise and automatic control method of copper ion concentration in the electrolyte during electroplating is as follows: 11. The lower end bag is in a flexible anode bag, and is suspended under the anode conductive rod. A micro-pressure detector is installed under the anode conductive rod. When the electrodeposition power supply is connected, the micro-pressure detector detects the pressure value in real time, and will start Pressure value P 0 And the subsequent pressure value Pn (n=1, 2, 3, ...) is transmitted to the signal control analysis unit. In the production of this embodiment, the electrodeposition time is 1h, and the signal analysis unit calculates 1.2 hours from the electrodeposition. The pressure change per unit time ΔP after min n =P n -P n-1 , every 1min is an interval, after calculated by the signal control analysis unit, compared ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com