Thermal insulation film for transparent glass and preparation method

A technology of thermal insulation and transparent glass, applied in the coating and other directions, can solve the problems of uneven dispersion of inorganic fillers, poor interface compatibility, poor thermal insulation effect, etc., to promote uniform dispersion and firm combination, good insulation Thermal insulation function, good barrier and shielding effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

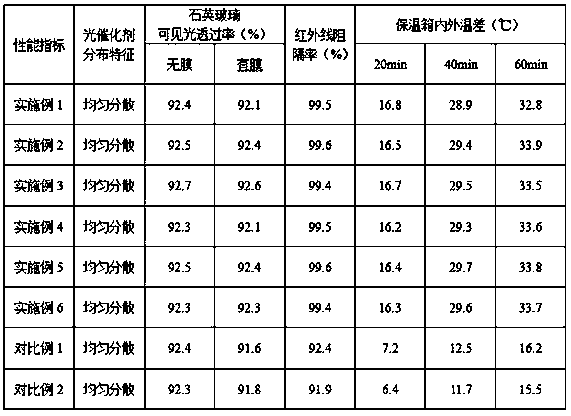

Examples

Embodiment 1

[0031] (1) Disperse nano-indium tin oxide in an aqueous solution of ethanol, add γ-(methacryloyl chloride) propyl trimethoxysilane, adjust the pH value to 8, transfer to a ball mill at a speed of 2300r / min for high-speed Ball milling, so that γ-(methacryloyl chloride) propyl trimethoxysilane is supported on the surface of nano indium tin oxide, then filtered, washed and dried to obtain modified indium tin oxide with C=C double bond on the surface; each raw material The parts by weight are 27 parts by weight of nano-indium tin oxide, 15 parts by weight of ethanol, 54 parts by weight of water, and 4 parts by weight of γ-(methacryloyl chloride)propyltrimethoxysilane;

[0032] (2) Disperse the mica powder in the aqueous solution of ethanol, add γ-(methacryloyl chloride) propyl trimethoxysilane, adjust the pH value to 8, transfer to the ball mill and perform high-speed ball milling at the speed of 2300r / min, Load γ-(methacryloyl chloride) propyltrimethoxysilane on the surface of mi...

Embodiment 2

[0043] (1) Disperse nano-indium tin oxide in an aqueous solution of ethanol, add γ-(methacryloyl chloride) propyl trimethoxysilane, adjust the pH value to 9, transfer to a ball mill at a speed of 2200r / min for high-speed Ball milling, so that γ-(methacryloyl chloride) propyl trimethoxysilane is supported on the surface of nano indium tin oxide, then filtered, washed and dried to obtain modified indium tin oxide with C=C double bond on the surface; each raw material The parts by weight are 25 parts by weight of nano-indium tin oxide, 13 parts by weight of ethanol, 59 parts by weight of water, and 3 parts by weight of γ-(methacryloyl chloride)propyltrimethoxysilane;

[0044] (2) Disperse the mica powder in the aqueous solution of ethanol, add γ-(methacryloyl chloride) propyltrimethoxysilane, adjust the pH value to 9, transfer to the ball mill and perform high-speed ball milling at the speed of 2200r / min, Load γ-(methacryloyl chloride) propyltrimethoxysilane on the surface of mic...

Embodiment 3

[0050] (1) Disperse nano-indium tin oxide in an aqueous solution of ethanol, add γ-(methacryloyl chloride) propyl trimethoxysilane, adjust the pH value to 8, transfer to a ball mill at a speed of 2500r / min for high-speed Ball milling, so that γ-(methacryloyl chloride) propyl trimethoxysilane is supported on the surface of nano indium tin oxide, then filtered, washed and dried to obtain modified indium tin oxide with C=C double bond on the surface; each raw material The parts by weight are 28 parts by weight of nano-indium tin oxide, 16 parts by weight of ethanol, 51 parts by weight of water, and 5 parts by weight of γ-(methacryloyl chloride)propyltrimethoxysilane;

[0051] (2) Disperse the mica powder in the aqueous solution of ethanol, add γ-(methacryloyl chloride) propyltrimethoxysilane, adjust the pH value to 8, transfer to the ball mill and perform high-speed ball milling at the speed of 2500r / min, Load γ-(methacryloyl chloride) propyltrimethoxysilane on the surface of mic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com