Graphene preservative and corrosion control method for mounting bracket

A mounting bracket, graphene technology, applied in anti-corrosion coatings, devices for coating liquid on the surface, coatings, etc., can solve problems such as anti-corrosion of passenger-specific signal mounting brackets, achieve good anti-corrosion effect, good acid and salt resistance, Evenly distributed effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

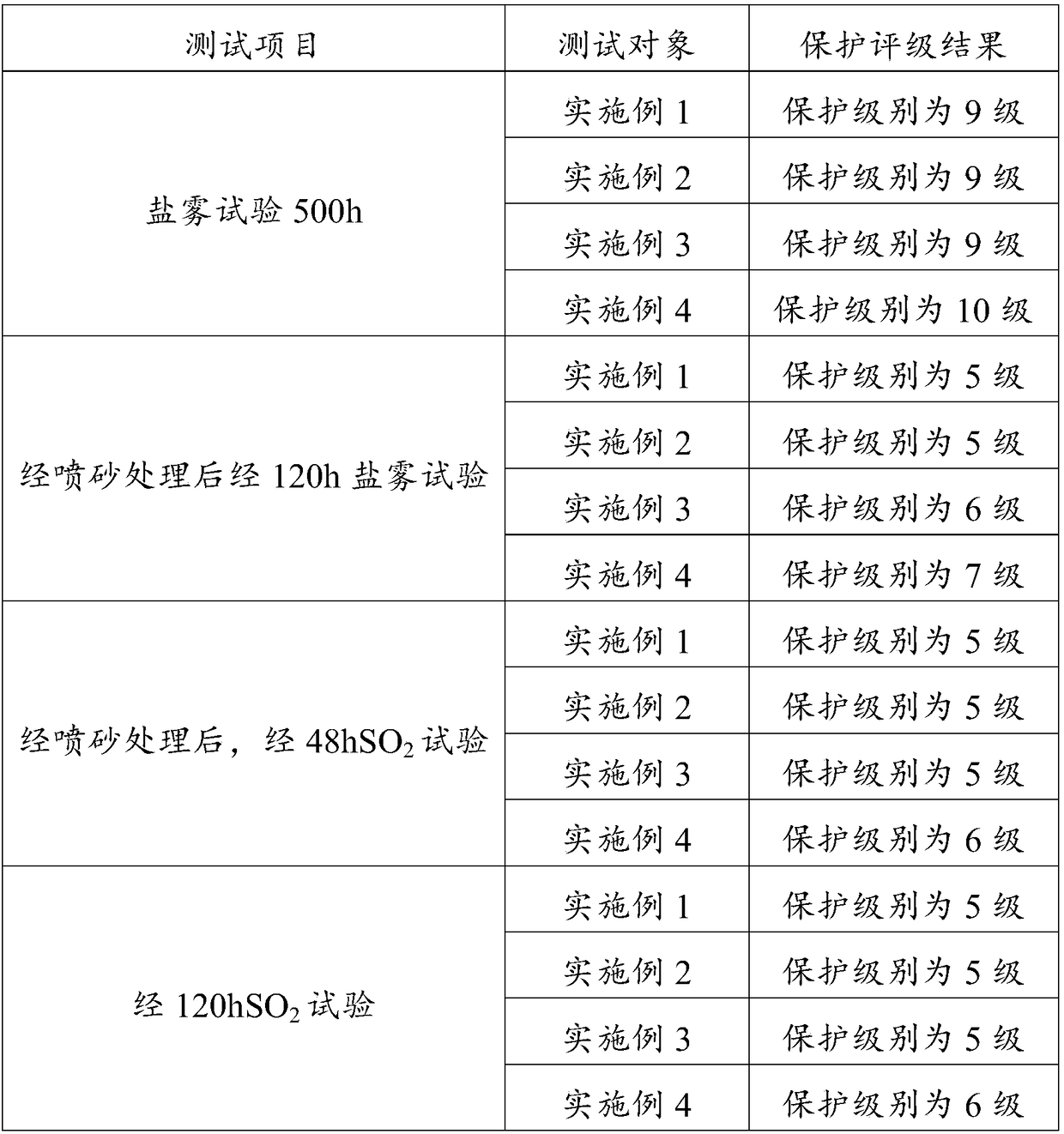

Examples

Embodiment 1

[0026] Graphene preservative comprises the following components by weight percent:

[0027] 26% epoxy resin, 5% silicon oxide, 0.5% modified graphene, 0.5% dispersant, 15% zinc oxide, 0.5% aluminum oxide, 5% curing agent, and the balance is solvent ethanol, the modified graphene The modifying agent is sodium dodecylsulfonate, and the weight ratio of the graphene to sodium dodecylsulfonate is 2:1. The particle size of the silicon oxide, zinc oxide and aluminum oxide is evenly 500-800 mesh. The preparation method of the graphene preservative is as follows: firstly, the modified graphene is added to ethanol, ultrasonically dispersed, then epoxy resin is added, stirred evenly, silicon oxide, zinc oxide, aluminum oxide are added, stirred evenly, and then added Dispersant and curing agent, ultrasonically dispersed evenly to obtain graphene preservative. The viscosity of the preservative is 13 Pa.s.

[0028] The anti-corrosion and anti-corrosion of the installation bracket of pass...

Embodiment 2

[0033] Graphene preservative comprises the following components by weight percent:

[0034] 56% of epoxy resin, 3% of silicon oxide, 3% of modified graphene, 1% of dispersant, 10% of zinc oxide, 3.5% of aluminum oxide, 10% of curing agent, and the balance is solvent propanol, the modified graphite The modification agent of alkene is sodium dodecylbenzene sulfonate, and the weight ratio of described graphene and sodium dodecylbenzene sulfonate is 1:1. The particle size of the silicon oxide, zinc oxide and aluminum oxide is evenly 500-800 mesh. The preparation method of the graphene preservative is as follows: firstly, the modified graphene is added to ethanol, ultrasonically dispersed, then epoxy resin is added, stirred evenly, silicon oxide, zinc oxide, aluminum oxide are added, stirred evenly, and then added Dispersant and curing agent, ultrasonically dispersed evenly to obtain graphene preservative. The viscosity of the preservative is 17 Pa.s.

[0035] The anti-corrosion...

Embodiment 3

[0040] Graphene preservative comprises the following components by weight percent:

[0041]40% epoxy resin, 4% silicon oxide, 1.2% modified graphene, 0.6% dispersant, 12% zinc oxide, 1% aluminum oxide, 6% curing agent, and the balance is solvent ethanol, the modified graphene The modifying agent is sodium dodecylbenzenesulfonate, and the weight ratio of graphene and sodium dodecylbenzenesulfonate is 1:1. The particle size of the silicon oxide, zinc oxide and aluminum oxide is evenly 500-800 mesh. The preparation method of the graphene preservative is as follows: firstly, the modified graphene is added to ethanol, ultrasonically dispersed, then epoxy resin is added, stirred evenly, silicon oxide, zinc oxide, aluminum oxide are added, stirred evenly, and then added Dispersant and curing agent, ultrasonically dispersed evenly to obtain graphene preservative. The viscosity of the preservative is 15 Pa.s.

[0042] The anti-corrosion and anti-corrosion of the installation bracket...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com