Method for preparing paraxylene from methylbenzene mixture

A p-xylene and mixture technology, which is applied in the field of fluidized bed catalysis, can solve problems such as reactor overheating, stability problems, and poor p-xylene selectivity indicators, so as to improve conversion rate, ensure stability, and guarantee Effects of Continuity and Reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

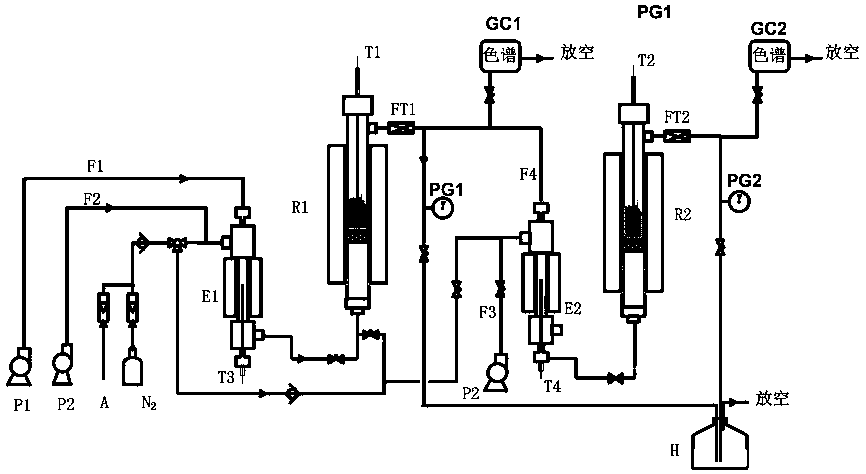

Method used

Image

Examples

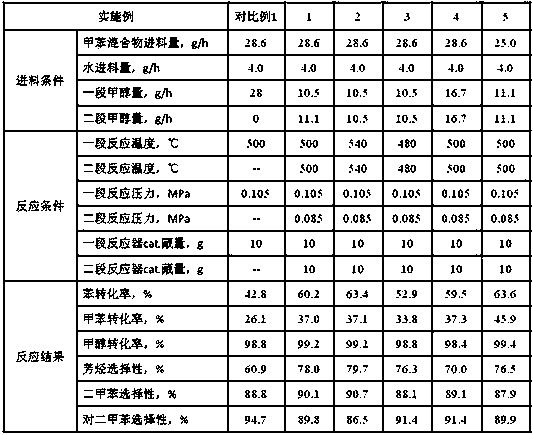

Embodiment 1

[0027] The reaction form of two fluidized bed reactors in series is adopted, toluene and water all enter from the first reactor, and methanol is divided into two streams and enters from the entrance of the first and second reactor respectively. Toluene mixtures with mass flow rates of 28.6g / h, 10.5 g / h and 4.0g / h respectively (the mass ratio of benzene to toluene is 3:7), methanol and water enter the first reactor for reaction after being vaporized and mixed. The product is uniformly mixed with the second stream of gas-phase methanol at a mass flow rate of 11.1 g / h, and then enters the second-stage fluidized-bed reactor to continue the reaction. The two reactors are filled with the same type of ZSM-5 molecular sieve catalyst, and the first and second stage reactors have a dense-phase catalyst storage capacity of 10g; the reaction temperature of the two stage reactors is 500 °C, and the first stage reaction The reaction pressure of the reactor is 0.105MPa(G), and the reaction p...

Embodiment 2

[0029] The reaction form of two fluidized bed reactors in series is adopted, toluene and water all enter from the first reactor, and methanol is divided into two streams and enters from the entrance of the first and second reactor respectively. Toluene mixed aromatics with mass flow rates of 28.6g / h, 10.5 g / h and 4.0g / h (mass ratio of benzene to toluene is 3:7), methanol and water enter the first reactor for reaction after being vaporized and mixed. The reaction product is uniformly mixed with the second stream of gas-phase methanol at a mass flow rate of 10.5 g / h, and then enters the second-stage fluidized-bed reactor to continue the reaction. The two reactors are filled with the same type of ZSM-5 molecular sieve catalyst, and the first and second stage reactors have a dense-phase catalyst storage capacity of 10g; the reaction temperature of the two stage reactors is 540 ° C, and the first stage reaction The reaction pressure of the reactor is 0.105MPa(G), and the reaction p...

Embodiment 3

[0031] The reaction form of two fluidized bed reactors in series is adopted, toluene and water all enter from the first reactor, and methanol is divided into two streams and enters from the entrance of the first and second reactor respectively. Toluene mixed aromatics with mass flow rates of 28.6g / h, 10.5 g / h and 4.0g / h (mass ratio of benzene to toluene is 3:7), methanol and water enter the first reactor for reaction after being vaporized and mixed. The reaction product is uniformly mixed with the second stream of gas-phase methanol at a mass flow rate of 10.5 g / h, and then enters the second-stage fluidized-bed reactor to continue the reaction. The two reactors are filled with the same type of ZSM-5 molecular sieve catalyst, and the first and second stage reactors have a dense-phase catalyst storage capacity of 10g; the reaction temperature of the two stage reactors is 480 ° C, and the first stage reaction The reaction pressure of the reactor is 0.105MPa(G), and the reaction p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com