Zipper tooth, preparation method and zipper with same

A technology of zipper teeth and plastic, applied in the field of zipper, can solve the problem of single style, and achieve the effect of simple preparation process, full particles and high degree of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

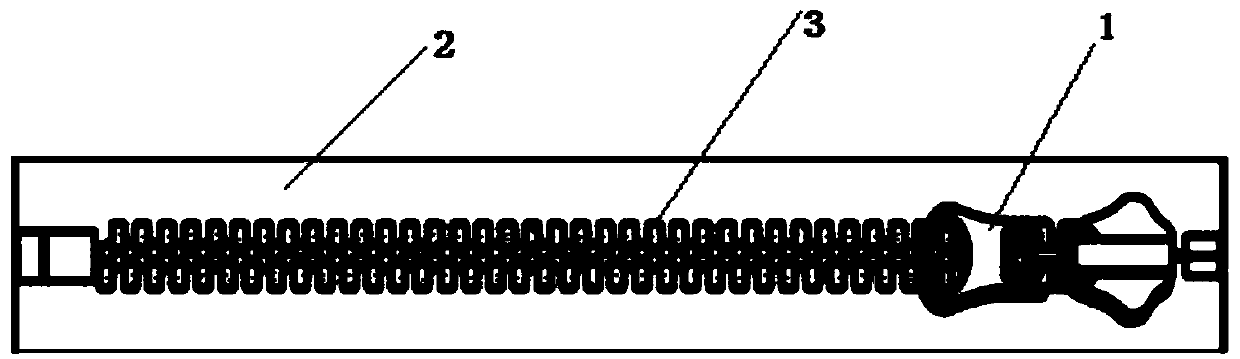

Image

Examples

Embodiment 1

[0030] This embodiment discloses a method for preparing a plastic zipper element with cyclic color points, which includes the following steps:

[0031] Step (1), take non-fusible organic toner and POM glue respectively by weight ratio of 1:90;

[0032] Step (2), taking the POM glue in the step (1) and adding it to a pulverizer for pulverization, pulverizing it to 100um to obtain POM colloidal particles;

[0033] Step (3), taking the non-meltable organic toner powder in the step (1) and the POM colloidal particles in the step (2), stirring and mixing uniformly to obtain a mixture;

[0034] Step (4), put the mixture in step (3) into the screw-type automatic feeder, when the mixture in the hopper of the injection molding machine is less than 0.5kg, the screw-type automatic feeder automatically feeds into the hopper of the injection molding machine, and the injection molding machine The barrel is heated to 190°C to melt the colloidal particles to obtain a liquid mixture;

[0035...

Embodiment 2

[0038] This embodiment discloses a method for preparing a plastic zipper element with cyclic color points, which includes the following steps:

[0039] Step (1), take non-fusible organic toner and PP glue respectively by weight ratio of 1:100;

[0040] Step (2), taking the PP glue in step (1) and adding it to a pulverizer for pulverization, pulverizing it to 400um to obtain PP colloidal particles;

[0041] Step (3), taking the non-fusible organic toner powder in step (1) and the PP colloidal particles in step (2) and stirring and mixing uniformly to obtain a mixture;

[0042] Step (4), put the mixture in step (3) into the screw-type automatic feeder, when the mixture in the hopper of the injection molding machine is less than 0.5kg, the screw-type automatic feeder automatically feeds into the hopper of the injection molding machine, and the injection molding machine The barrel is heated to 195°C to melt the colloidal particles to obtain a liquid mixture;

[0043] Step (5), u...

Embodiment 3

[0046] This embodiment discloses a method for preparing a plastic zipper element with cyclic color points, which includes the following steps:

[0047] Step (1), take non-fusible organic toner and PMMA glue respectively by weight ratio of 1:110;

[0048] Step (2), get the PMMA glue in step (1) and add in pulverizer and pulverize, it is pulverized to 800um, obtains PMMA colloid;

[0049] Step (3), taking the non-meltable organic color pink powder in the step (1) and the PMMA colloidal particles in the step (2) are stirred and mixed uniformly to obtain a mixture;

[0050] Step (4), put the mixture in step (3) into the screw-type automatic feeder, when the mixture in the hopper of the injection molding machine is less than 0.5kg, the screw-type automatic feeder automatically feeds into the hopper of the injection molding machine, and the injection molding machine The barrel is heated to 195°C to melt the colloidal particles to obtain a liquid mixture;

[0051] Step (5), under t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com