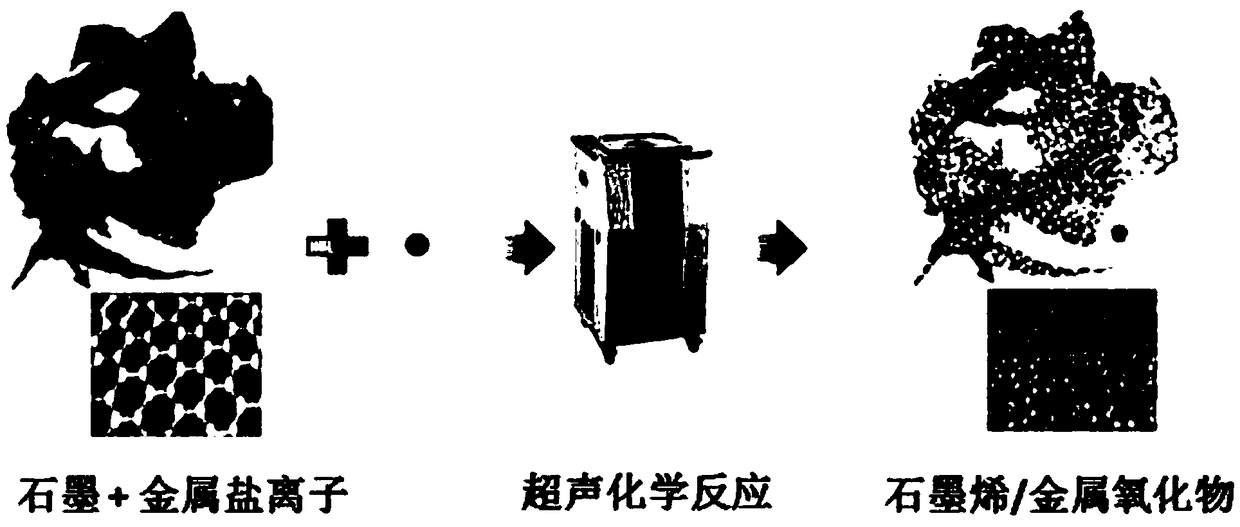

In-situ preparation of graphene composite electrode materials by ultrasonic chemical method

A graphene composite and electrode material technology, applied in the directions of hybrid capacitor electrodes, battery electrodes, electrochemical generators, etc., can solve the problems of reduced dispersibility, complicated procedures, affected performance, etc., and achieves low production cost, simple method and process, The effect of improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

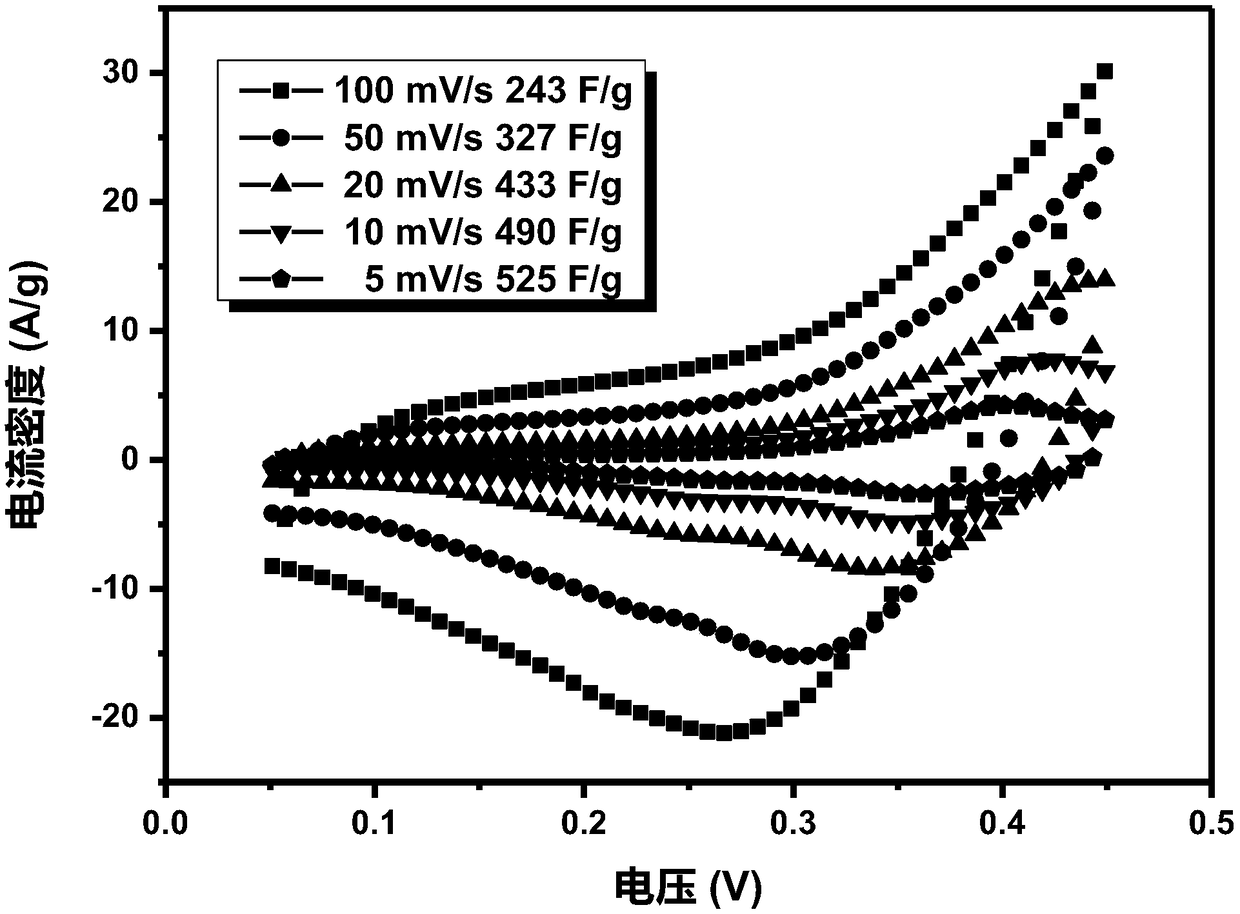

[0037] In this embodiment one, graphene / Co is prepared in situ by ultrasonic chemistry 3 o 4 Composite electrode material.

[0038] Preparation:

[0039] ① Weigh 50 mg of artificial graphite, add it to 100 mL of water, and ultrasonically treat it in a water bath for 30 minutes to prepare a 0.5 mg / mL graphite dispersion.

[0040] ②Add 2.4mmol Co(CH 3 COO) 2 4H 2 O was added to the above-mentioned graphite dispersion liquid, using a probe-type ultrasonic machine, set the temperature at 50°C, the power was 600W, and the ultrasonic time was 1h.

[0041] ③Slowly add 400mg (NH 4 ) 2 S 2 o 8 aqueous solution, continue to sonicate for 2h.

[0042] ④ The obtained product was repeatedly suction-filtered and washed with water and ethanol until the filtrate was neutral, and finally dried in a vacuum oven at 60°C for 12 hours to obtain the product graphene / Co 3 o 4 Composite electrode material.

[0043] ⑤ Put the product in a tube furnace, raise the temperature to 300° C. for ...

Embodiment 2

[0049] In this embodiment two, graphene / SnO is prepared in situ by ultrasonic chemistry 2 Composite electrode material.

[0050] Preparation:

[0051] ① Weigh 100 mg of graphite oxide and add it to 100 mL of water / ethanol mixed solvent (V H2O :V EtOH =1:3), sonicate for 30min to disperse the solution evenly, and make 100mL 1mg / mL graphite dispersion.

[0052] ② 1.34mmol anhydrous SnCl 2 Add it into the above-mentioned graphite dispersion liquid, use an ultrasonic cleaning machine, set the temperature at 50°C, the power at 300W, and the ultrasonic time for 2 hours to carry out the ultrasonic chemical reaction.

[0053] ③ The obtained product was repeatedly centrifuged and washed with water and ethanol until the solution was neutral, and finally dried in a vacuum oven at 60°C for 12 hours to obtain the product graphene / SnO 2 Composite electrode material.

[0054] ④ Place the product in a tube furnace, raise the temperature to 220° C. for 6 hours at a rate of 5° C. / min in a...

Embodiment 3

[0059] In this embodiment three, graphene / MnO is prepared in situ by ultrasonic chemistry 2 Composite electrode material.

[0060] Preparation:

[0061] Weigh natural graphite to make 100mL 1mg / mL graphite dispersion, and ultrasonically treat it for 30min to make the solution evenly dispersed.

[0062] ①Add 4.8mmol MnSO 4 Add it to the above graphite dispersion, use a probe-type ultrasonic machine, set the temperature at 50°C, power at 600W, and ultrasonic time for 30 minutes.

[0063] ②Add 10mL KMnO containing 3.2mmol 4 Aqueous solution, continue ultrasonic reaction 2h.

[0064] ③ The obtained product was repeatedly centrifuged with water and ethanol, washed by dialysis until the solution was neutral, and finally dried in a vacuum oven at 60°C for 12 hours to obtain the product graphene / MnO 2 Composite electrode material.

[0065] ④ Place the product in a tube furnace, raise the temperature to 500° C. for 4 hours at a heating rate of 10° C. / min in an air atmosphere, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com