An operation and maintenance management system and method for a heating, ventilating and air-conditioning system

A HVAC system and operation and maintenance management technology, applied in the direction of instruments, etc., can solve problems such as difficult to guarantee safe and stable operation, unable to reduce customer complaint rate, unable to guarantee repair feedback rate, etc., to ensure authenticity and timeliness, and realize Timely and professional processing, reducing the effect of idle spare parts inventory

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

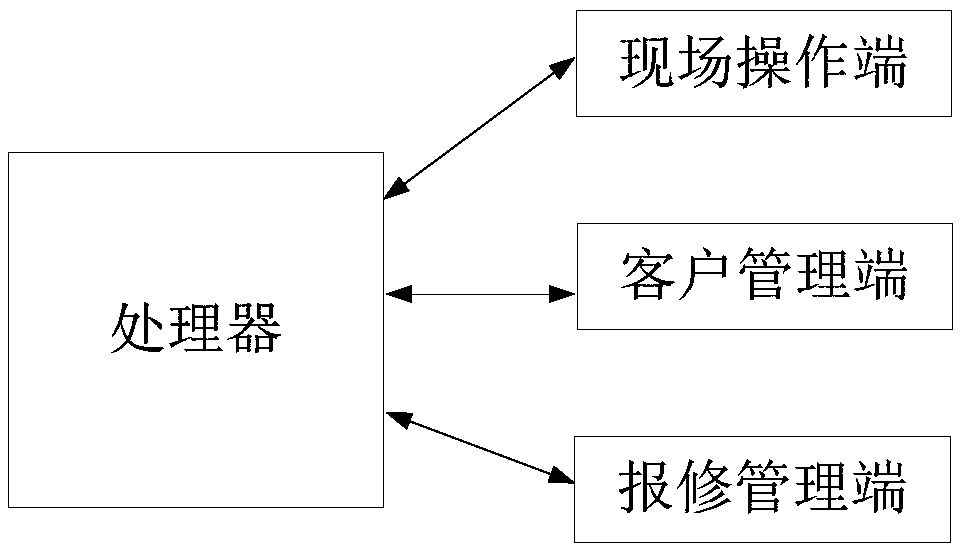

[0051] In a typical implementation of the present application, such as figure 1 As shown, an operation and maintenance management system for HVAC systems is provided. The system includes an on-site operation terminal, a customer management terminal, a repair management terminal and a processor. The on-site operation terminal, the customer management terminal, and the repair management Processor communication connection.

[0052] The on-site operation terminal is configured to input the project equipment and project information, inspection information, key equipment operating parameter status and task response status of the HVAC system in real time, input and report spare parts; Maintenance tasks, fault repair work orders and alarm information, feedback maintenance progress to the processor.

[0053] The client management terminal is configured to obtain key data from the processor, system comprehensive evaluation indicators (system stability, energy consumption indicators, re...

Embodiment 2

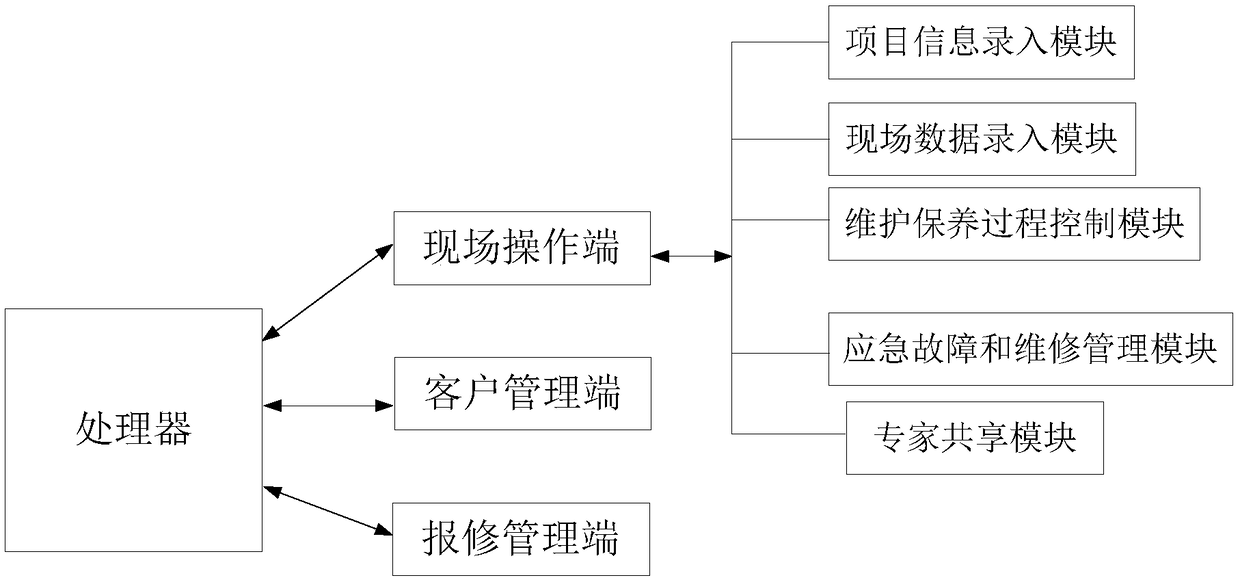

[0058] In order to make those skilled in the art understand the present invention better, enumerate a more detailed embodiment below, as figure 2 As shown, the embodiment of the present invention provides an operation and maintenance management system for HVAC systems. The system includes an on-site operation terminal, a customer management terminal, a repair management terminal and a processor. The management terminals are respectively connected to the processors through communication.

[0059] The on-site operation terminal is configured to input the project equipment and project information, inspection information, key equipment operating parameter status and task response status of the HVAC system in real time, input and report spare parts; Maintenance tasks, fault repair work orders and alarm information, feedback maintenance progress to the processor.

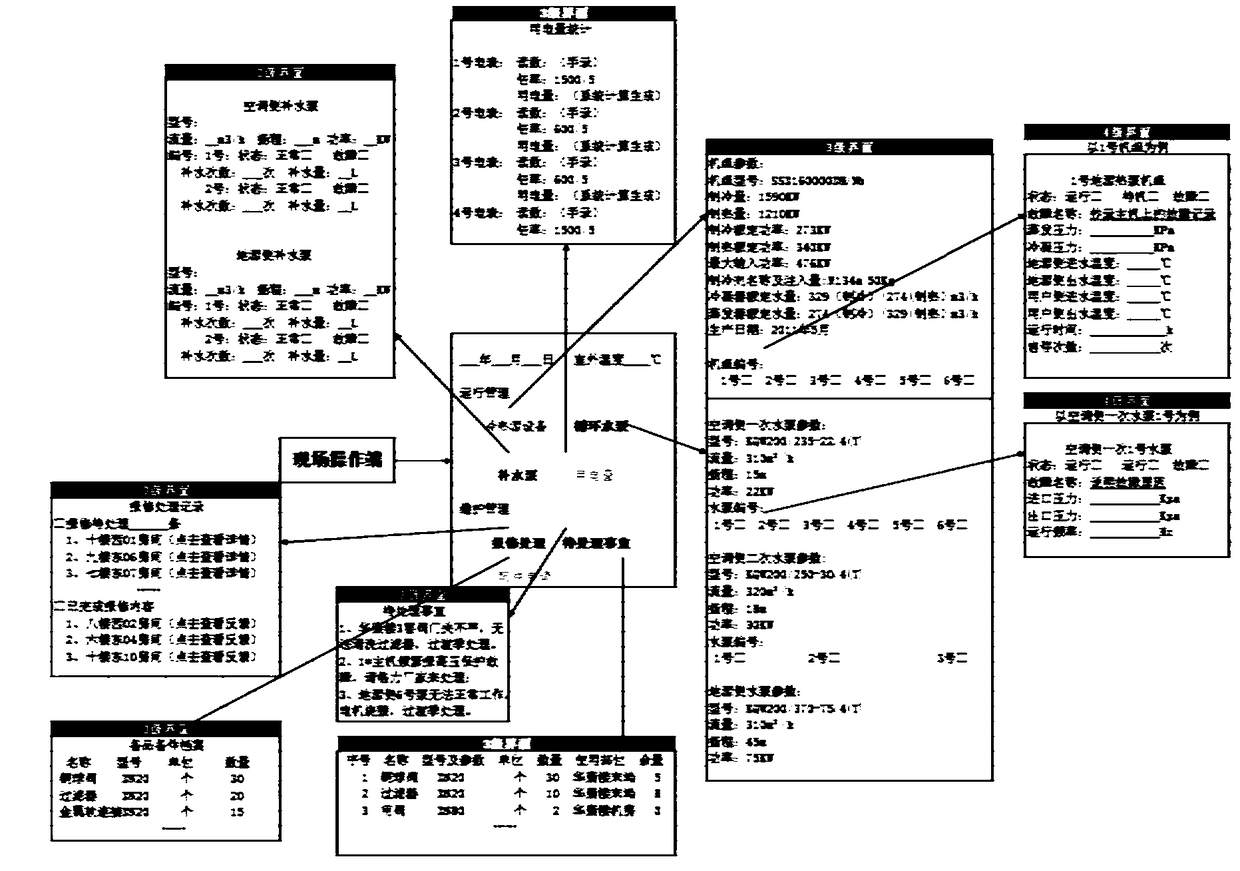

[0060] Input inspection information, status, task response status, etc. in real time through the on-site operation te...

Embodiment 3

[0078] corresponding to the above figure 1 and figure 2In the system embodiment shown, the embodiment of the present invention provides an operation and maintenance management method for an HVAC system, the method includes the following steps:

[0079] The on-site operation terminal inputs the project information, equipment operating status and operating parameters of the HVAC system, and sends them to the processor;

[0080] The processor receives and stores the operating status and operating parameters of the equipment, analyzes the operating data of the equipment and the entered equipment information, obtains the remaining maintenance time, date and maintenance content, formulates the equipment maintenance cycle, and sends it to the on-site operation terminal within the maintenance cycle Maintenance task, the on-site operation terminal receives the maintenance task issued by the processor, prompts the maintenance personnel to perform the maintenance work, enters the statu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com