Electronic pneumatic separating and closing executing mechanism

An electro-pneumatic and actuator technology, applied to clutches, mechanical equipment, etc., can solve problems such as long response time, low transmission efficiency, and complex systems, and achieve the effects of reducing clutch plate wear, eliminating bumps and other vibrations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The content of the present invention will be clearly and completely described below in conjunction with the accompanying drawings. Apparently, the described embodiments are part of the embodiments of the present invention, not all of them. The embodiments in the present invention and other embodiments obtained by persons of ordinary skill in the art without creative efforts all belong to the protection scope of the present invention.

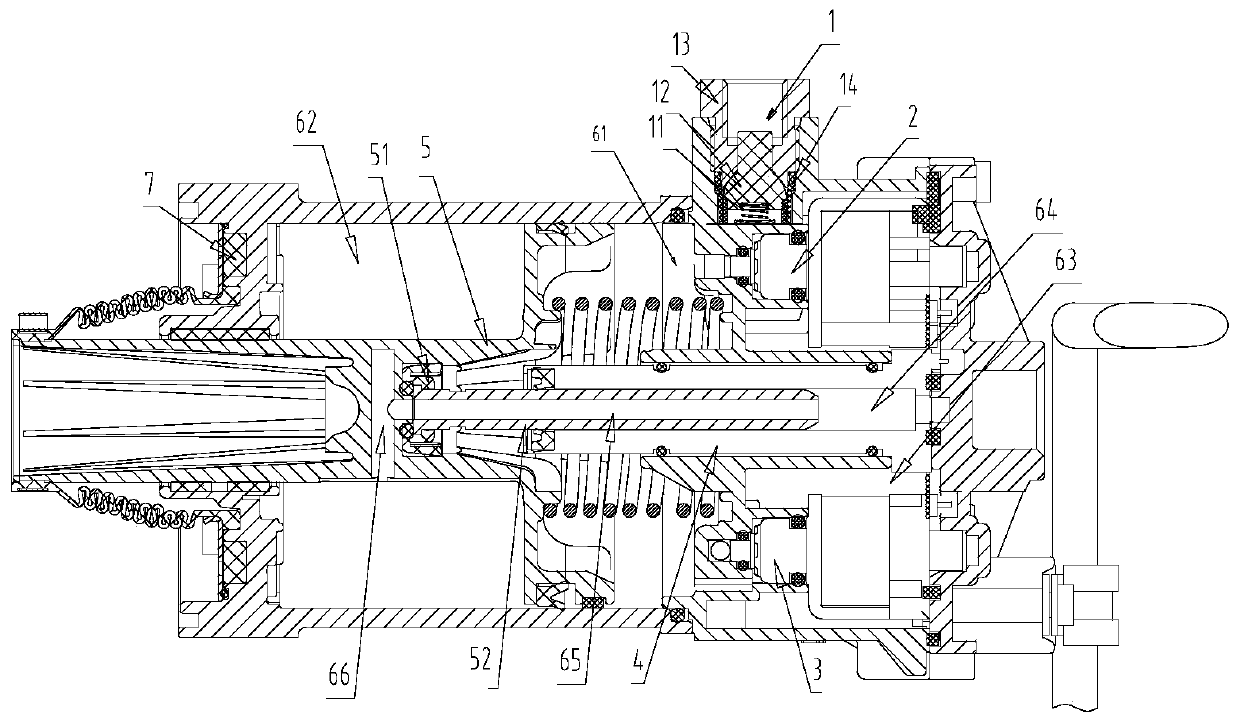

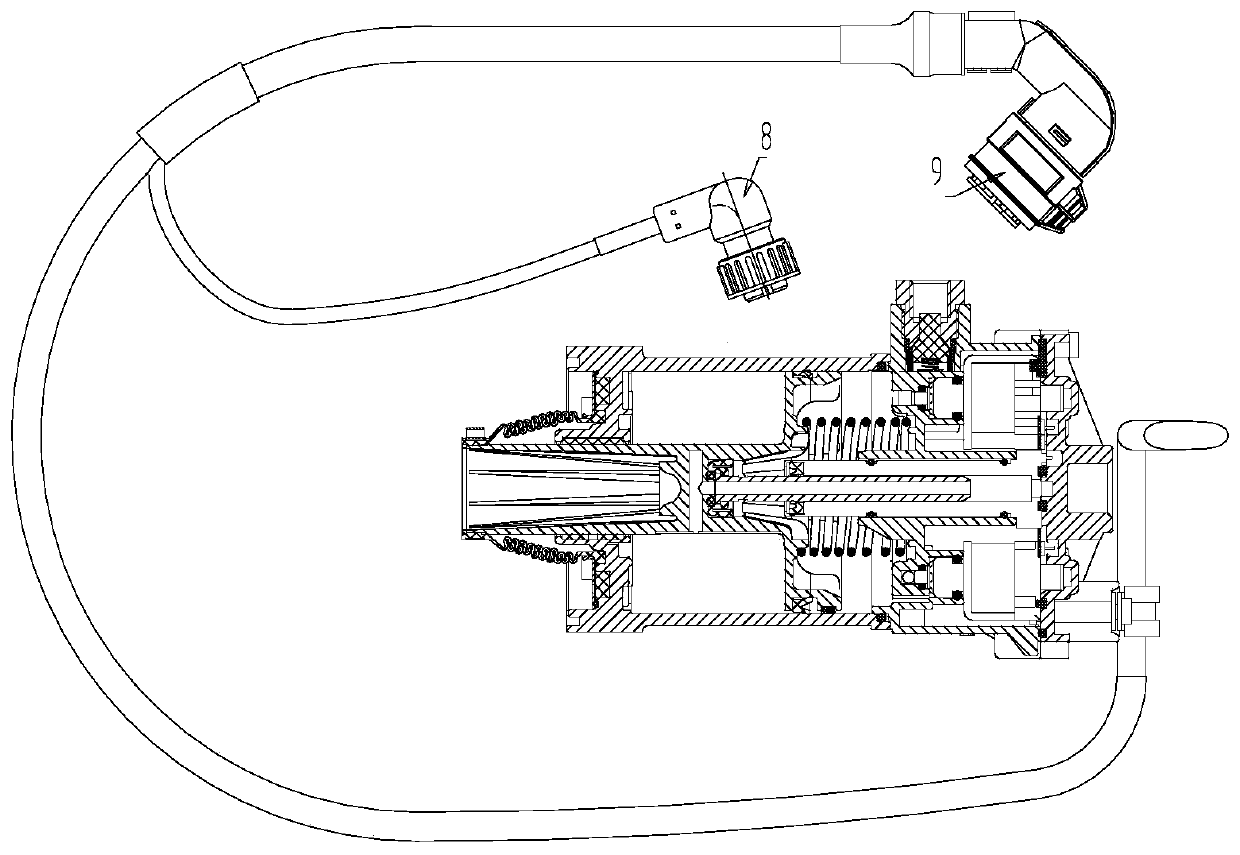

[0026] figure 1 It is a structural schematic diagram of the electropneumatic clutch actuator of the present invention. Such as figure 1 As shown, this state is the initial diagram after the electropneumatic clutch actuator is loaded. When a group of separation solenoid valves 2 are not powered, the solenoid valves seal the air pressure input from the air inlet 1 and prevent the air pressure from entering the first air cavity 61 . A valve spring 11 and a one-way valve 12 can be installed on the air inlet 1 to prevent the reverse output ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com