A multi-dimensional direction selection assembly optimization method based on hybrid particle swarm optimization algorithm

A hybrid particle swarm and direction selection technology is applied in the multi-dimensional dimension chain optimization of parts and its selection and assembly pairing. The multi-dimensional direction selection assembly optimization field based on the hybrid particle swarm algorithm can solve the problem of product assembly success rate and assembly function requirements that cannot meet the design requirements. Requirements, assembly success rate, problems with assembly function requirements, parts size and geometric accuracy cannot be guaranteed, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0079] The embodiments are further described in detail below with reference to the accompanying drawings.

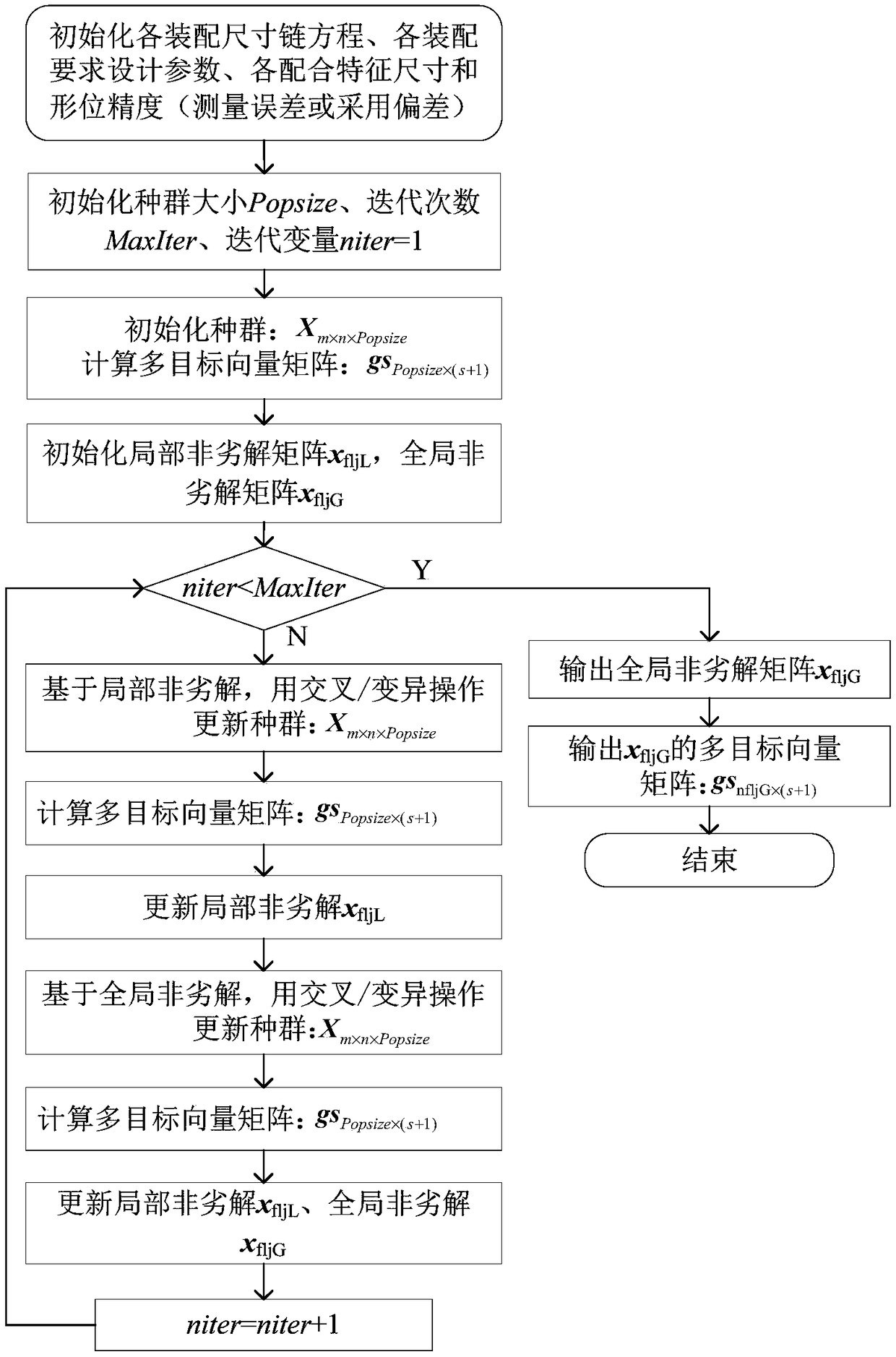

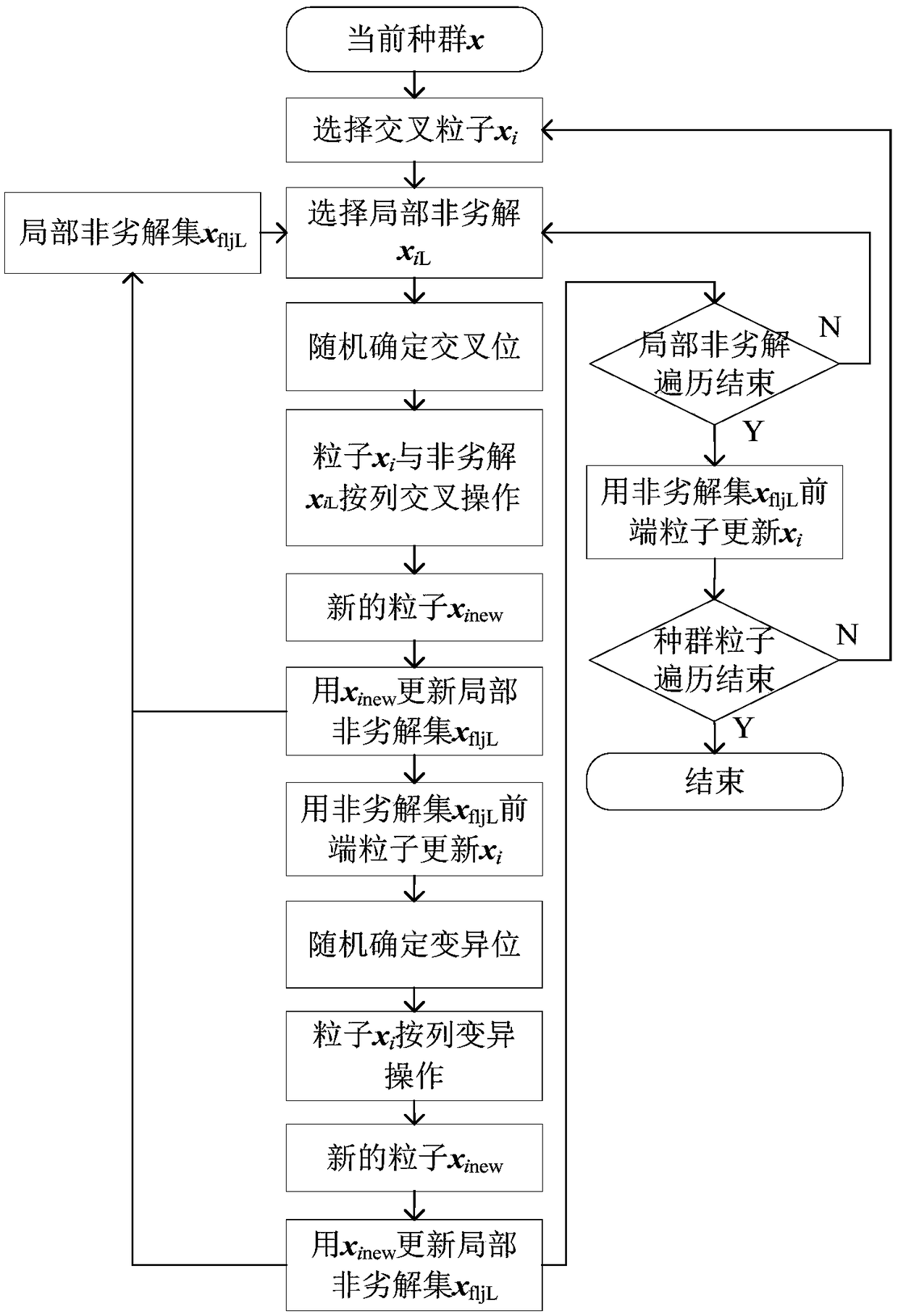

[0080] A multi-dimensional orientation selection assembly optimization method based on hybrid particle swarm optimization, comprising the steps of:

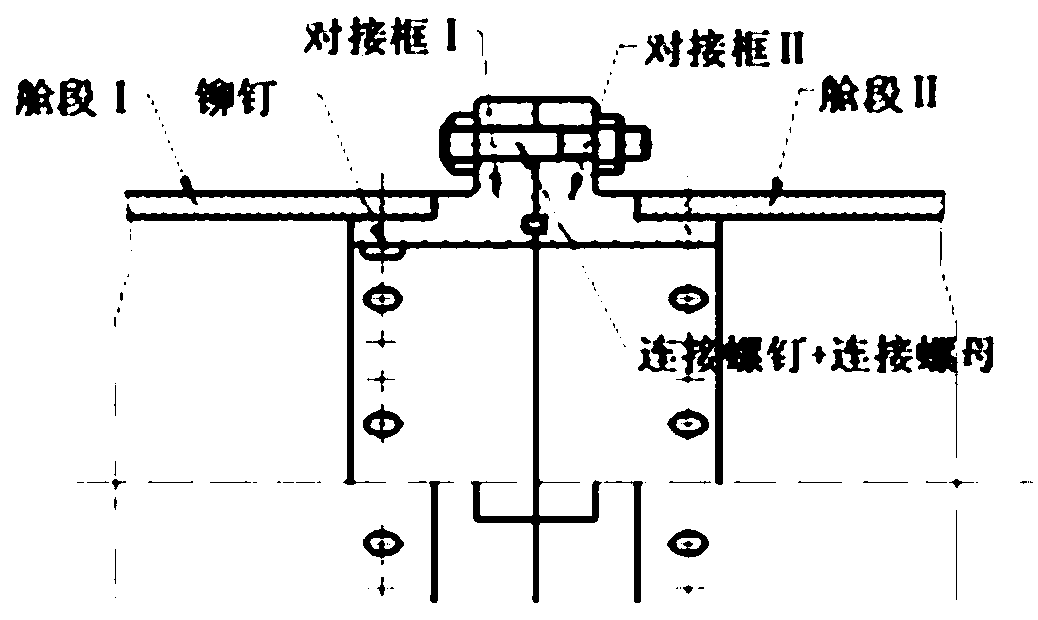

[0081] S1. Construct a multi-dimensional dimension chain model for the batch assembly of various parts;

[0082] S2, constructing a multi-objective optimization model for batch selection and assembly of various parts based on the multi-dimensional dimension chain model;

[0083] S3, using the hybrid particle swarm algorithm to solve the multi-objective optimization model, and finally obtain an assembly pairing scheme in the batch selection assembly of various parts.

[0084] In the step S1, the multi-dimensional dimension chain model is used to consider the assembly guarantee problem required by multiple assembly functions of the product at the same time when assembling various parts, and convert the assembly guarantee pro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com