A kind of ionic poss block copolymer base humidity sensor and preparation method

A block copolymer, humidity sensor technology, applied in instruments, scientific instruments, material analysis by electromagnetic means, etc., can solve the problems of poor controllability, control, instability of humidity sensitive components, etc., to improve durability and long-term Stability, improved durability and mechanical properties, improved hydrophilic-hydrophobic phase separation behavior

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

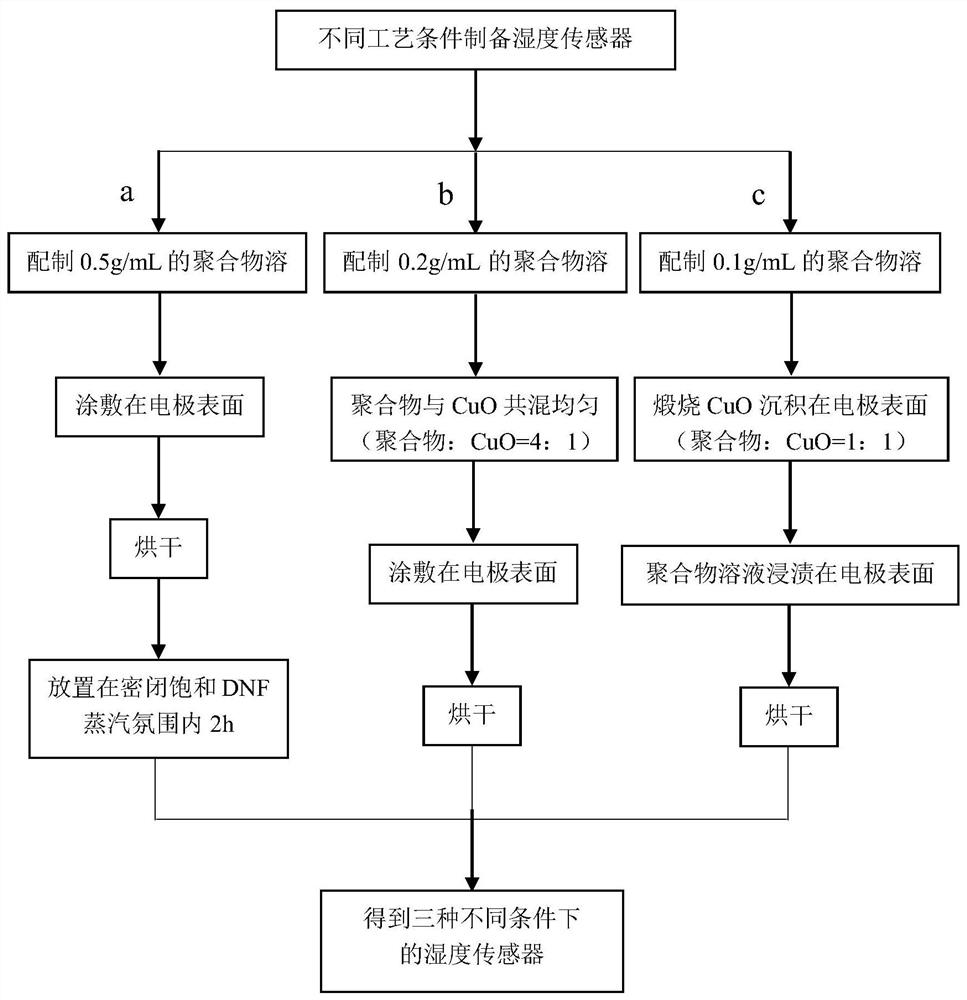

[0040] Step 1: Take 0.05g of tadpole-type organic-inorganic hybrid POSS grafted methyl methacrylate-sulfonated styrene block copolymer (POSS-g-PMMA-b-SPS) with a block ratio of 1:1 Dissolve in 100uL N,N-dimethylformamide, take 10uL of the prepared solution and apply it on the surface of a clean interdigital electrode, and dry it in a vacuum oven at 60°C to constant weight. After the obtained humidity sensor was taken out, it was placed in a closed saturated N,N-dimethylformamide atmosphere, and stood for 2 hours to obtain an annealed humidity sensor. Preparation process such as figure 1 -a shown.

[0041] Step 2: Take 0.02g of tadpole-type organic-inorganic hybrid POSS grafted methyl methacrylate-sulfonated styrene block copolymer (POSS-g-PMMA-b-SPS) with a block ratio of 1:1 Dissolve in 100uL N,N-dimethylformamide, add 5mg of porous CuO according to the weight ratio of polymer to CuO of 4:1, put the blended solution into an ultrasonic cleaner and mix evenly, take 10uL of th...

Embodiment 2

[0043] Step 1: Take 0.05g of tadpole-type organic-inorganic hybrid POSS grafted methyl methacrylate-sulfonated styrene block copolymer (POSS-g-PMMA-b-SPS) with a block ratio of 1:3 Dissolve in 100uL N,N-dimethylformamide, take 10uL of the prepared solution and apply it on the surface of a clean interdigital electrode, and dry it in a vacuum oven at 60°C to constant weight. After the obtained humidity sensor was taken out, it was placed in a closed saturated N,N-dimethylformamide atmosphere, and stood for 2 hours to obtain an annealed humidity sensor. Preparation process such as figure 1 -a shown.

[0044] Step 2: Take 0.02g of tadpole-type organic-inorganic hybrid POSS grafted methyl methacrylate-sulfonated styrene block copolymer (POSS-g-PMMA-b-SPS) with a block ratio of 1:3 Dissolve in 100uL N,N-dimethylformamide, add 5mg of porous CuO according to the weight ratio of polymer to CuO of 4:1, put the blended solution into an ultrasonic cleaner and mix evenly, take 10uL of the ...

Embodiment 3

[0046] Step 1: Take 0.05g of tadpole-type organic-inorganic hybrid POSS grafted methyl methacrylate-sulfonated styrene block copolymer (POSS-g-PMMA-b-SPS) with a block ratio of 1:1 Dissolve in 100uL N,N-dimethylformamide, take 10uL of the prepared solution and apply it on the surface of a clean interdigital electrode, and dry it in a vacuum oven at 60°C to constant weight. After the obtained humidity sensor was taken out, it was placed in a closed saturated N,N-dimethylformamide atmosphere, and stood for 2 hours to obtain an annealed humidity sensor. Preparation process such as figure 1 -a shown.

[0047] Step 2: Take 0.01g of tadpole-type organic-inorganic hybrid POSS grafted methyl methacrylate-sulfonated styrene block copolymer (POSS-g-PMMA-b-SPS) with a block ratio of 1:1 Dissolve in 100uL N,N-dimethylformamide, according to the weight ratio of polymer to CuO 1:1, take 10mg porous CuO by calcining, deposit CuO on the surface of the interdigitated electrode, and then plac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com