Mix proportion optimization method of low-freezing point asphalt mixture

A technology of asphalt mixture and optimization method, which is applied in the direction of material analysis, specific gravity measurement, material inspection products, etc., can solve the problems of insufficient durability, deicing effect and durability, etc., achieve significant social benefits, promote development, and save manpower and material resources Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

[0039] Specific embodiment 1: The method for optimizing the mixing ratio of the low freezing point asphalt mixture in this embodiment is implemented in the following steps:

[0040] 1. Preparation of raw materials for low freezing point asphalt mixture and cementitious materials:

[0041] Weigh asphalt, coarse aggregate, fine aggregate, low-freezing point filler and mineral powder as the raw materials of low-freezing point asphalt mixture;

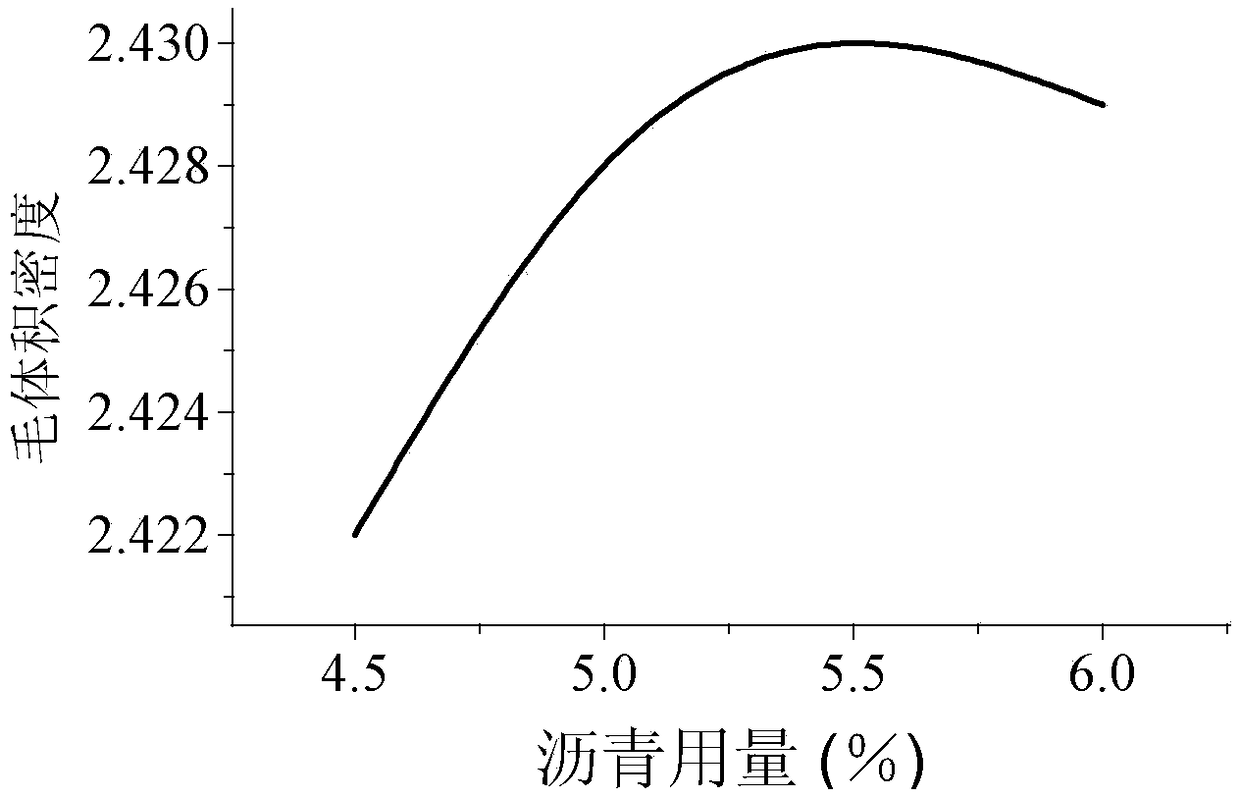

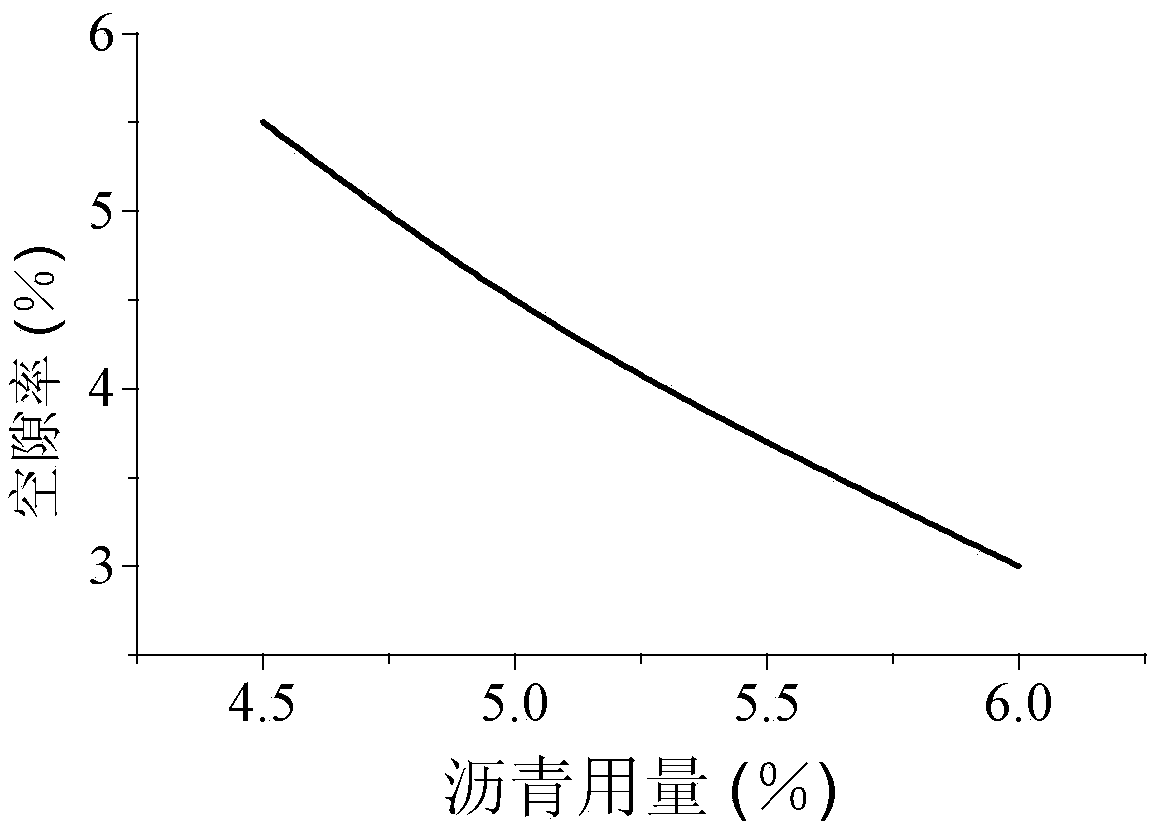

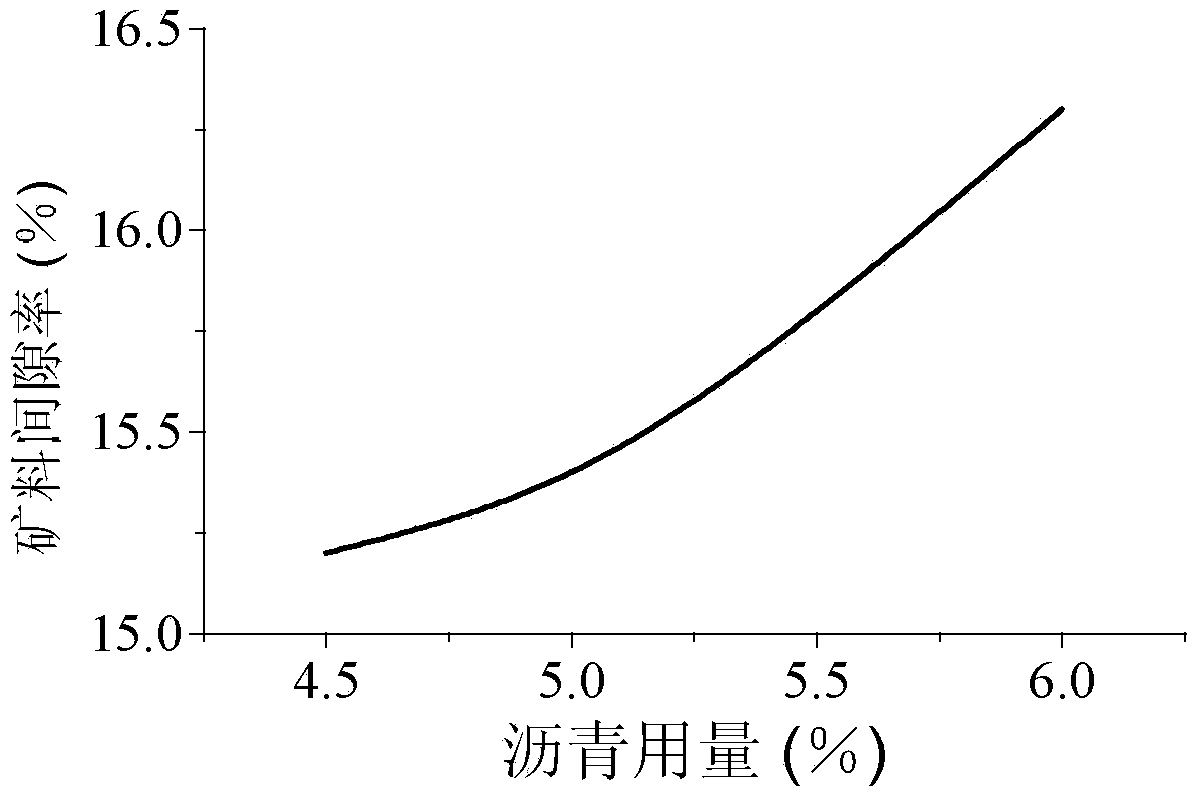

[0042] 2. Determination of the best asphalt dosage:

[0043] a. Preparation of Marshall test piece: preset (appropriate) mixture asphalt dosage, with the preset mixture asphalt dosage as the median value, and change the median asphalt dosage at 0.3% to 0.5% intervals, select at least 4 Different amounts of asphalt mixture, mix different amounts of asphalt with coarse aggregates, fine aggregates, low-freezing point fillers and mineral powders, and compact to obtain Marshall specimens. Each Marshall specimen has the same mineral gradation. ;

[0044...

specific Embodiment approach 2

[0064] Specific embodiment two: this embodiment is different from specific embodiment one in that the raw materials of the low freezing point asphalt mixture in step one all meet the requirements of "Technical Specification for Construction of Highway Asphalt Pavements" (JTG F40-2004).

specific Embodiment approach 3

[0065] Specific embodiment three: This embodiment is different from specific embodiment one or two in that the coarse aggregate in step one is crushed stone, and the fine aggregate is machine-made sand.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com