Segmental prefabricated bridge mounting linear shape control method

A technology of linear control and segmental beams, which is applied in the direction of bridges, bridge construction, erection/assembly of bridges, etc., can solve problems affecting construction efficiency, joint construction quality and durability, etc., to improve work efficiency and reduce the number of uses Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

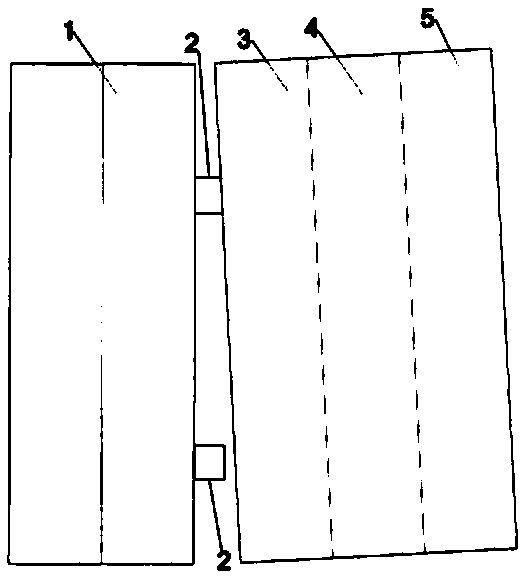

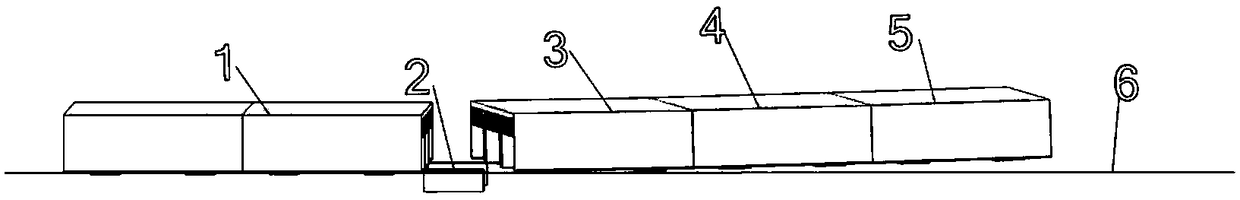

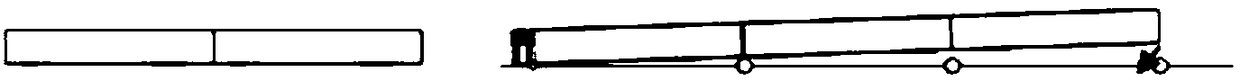

[0030] refer to figure 1 , figure 2 , image 3 , a method for controlling the alignment of segmental prefabricated bridges, comprising the following steps: after the segmental girders are prefabricated, installing measuring points, measuring the coordinates of the measuring points in the factory coordinate system, and calculating the node The measuring point coordinates of the section beam in the installation coordinate system;

[0031] After the first section beam 3 is installed, the coordinates of the measured measuring points are verified with the calculated coordinates to ensure that the error is ≤±2mm, and the first section beam 3 and the pier top block 1 are temporarily fixed;

[0032] Continue to install the second segmental beam 4, which is bonded and fixed between the second segmental beam 4 and the first segmental beam 3; then install the third segmental beam 5, the third segmental beam 5 and the first segmental beam 3 The two segmental beams 4 are bonded and fix...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com