A concrete telescopic conduit based on wireless remote control dry operation

A technology of wireless remote control and dry operation, which is applied in the field of concrete telescopic conduits and concrete pump conduits to achieve the effects of rapid pouring, convenient operation, and simple process flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

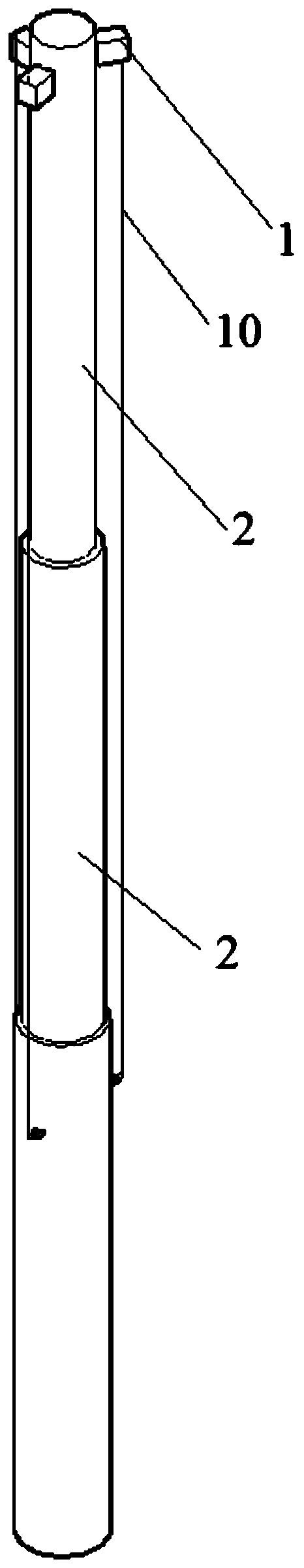

[0026] In the following, the present invention will be illustrated by taking the three-stage catheter as an example in conjunction with the accompanying drawings.

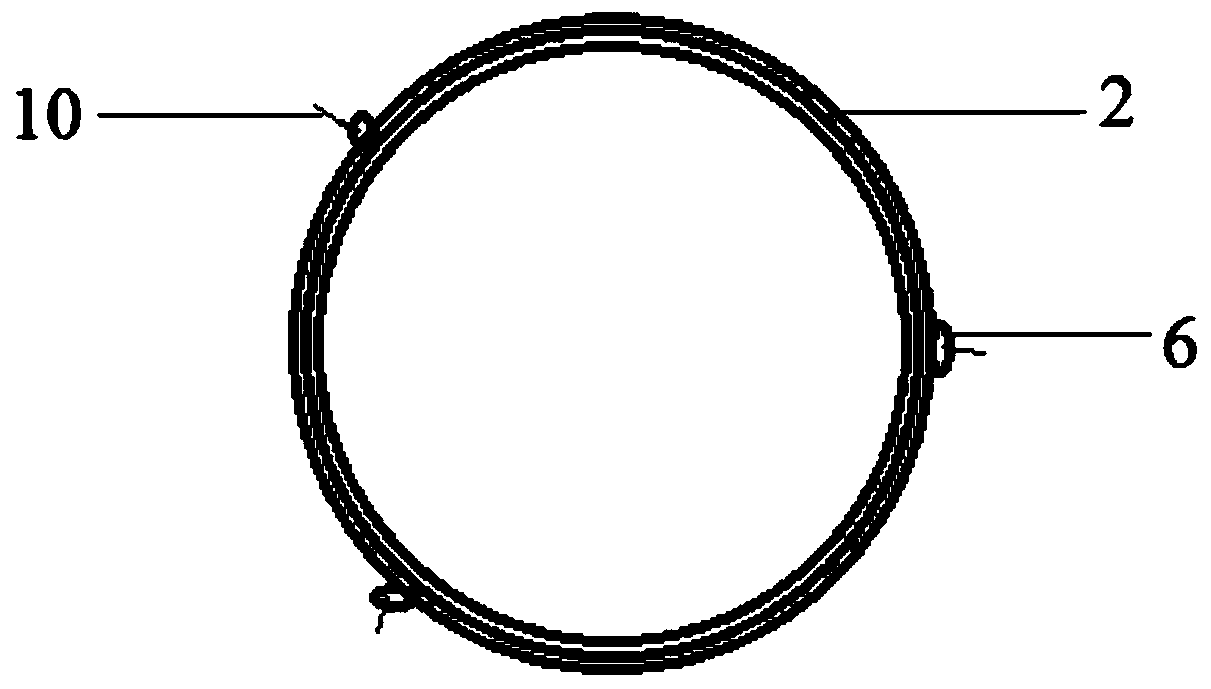

[0027] Such as Figure 1 to Figure 5 As shown, a concrete telescopic conduit based on wireless remote control dry operation, including a miniature hoist 1, a control device, and a conduit 2 that is sequentially set and connected in multiple stages from top to bottom, figure 1 The middle is a three-stage conduit, and the diameter of the conduit 2 in the set increases sequentially from top to bottom. The top of the first-stage conduit 2 on the top is provided with a fixing ring 6 connected to the pump pipe of the concrete pump truck. Each stage of conduit 2 is connected to the next There is a limit device between the stage conduits 2 to prevent the relative slippage of the two conduits. Multiple conduits 2 are shrinked and nested together, and can also be naturally sagging and elongated under the action of gravity. T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com