A method for installing a chain track

An installation method and a chain-type technology, which is applied in the erection/assembly of bridges, buildings, bridge construction, etc., can solve the problems of long installation time in the air, personnel in the installation method, and great safety threats, and achieve easy on-site operation, saving personnel, and The effect of reducing security risks

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

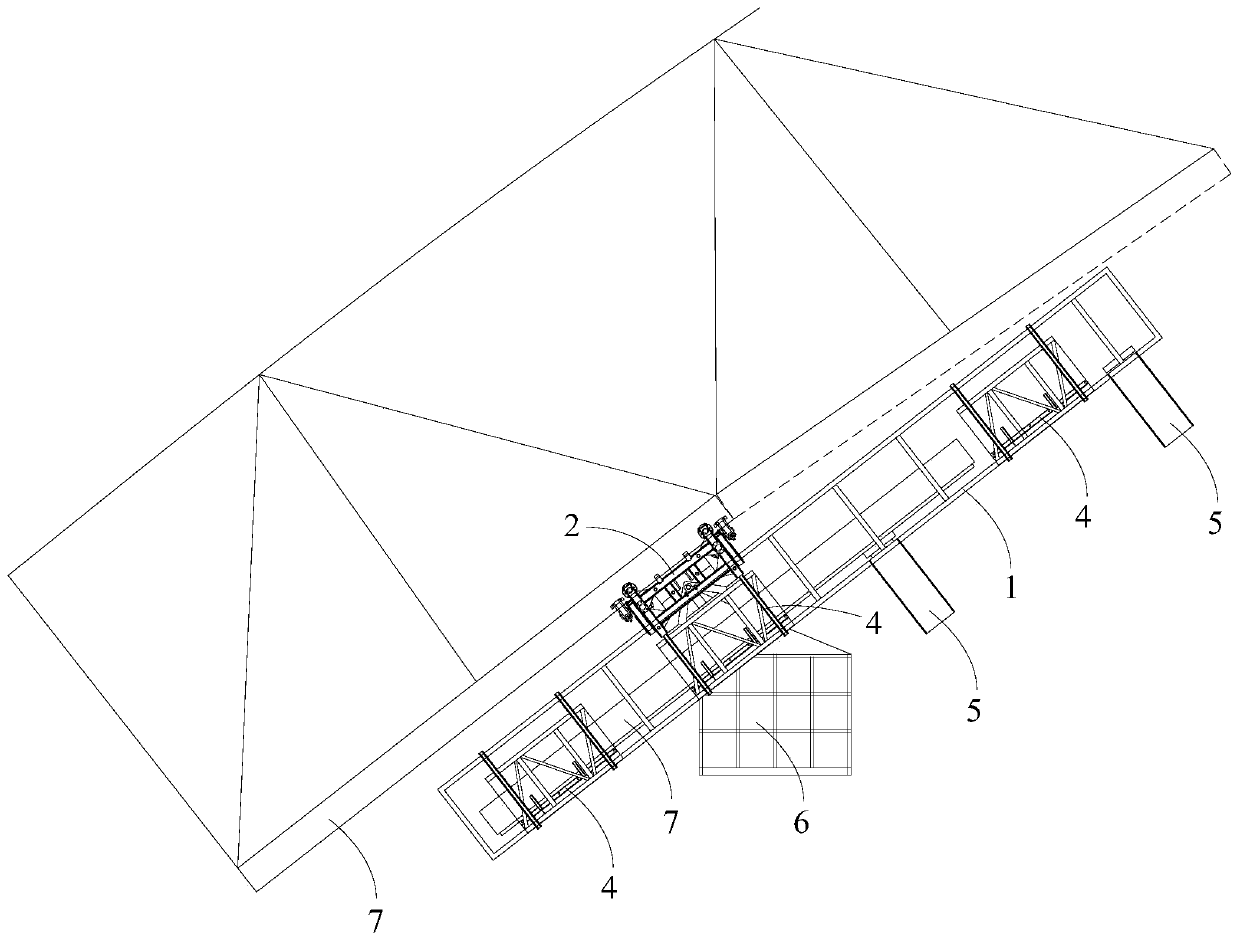

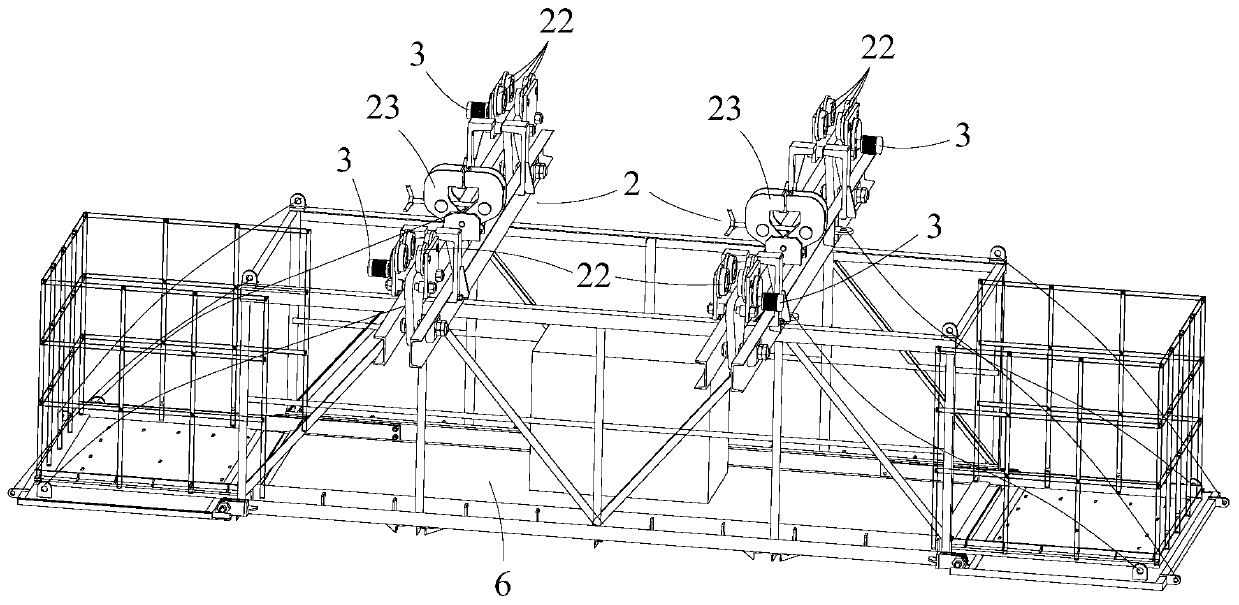

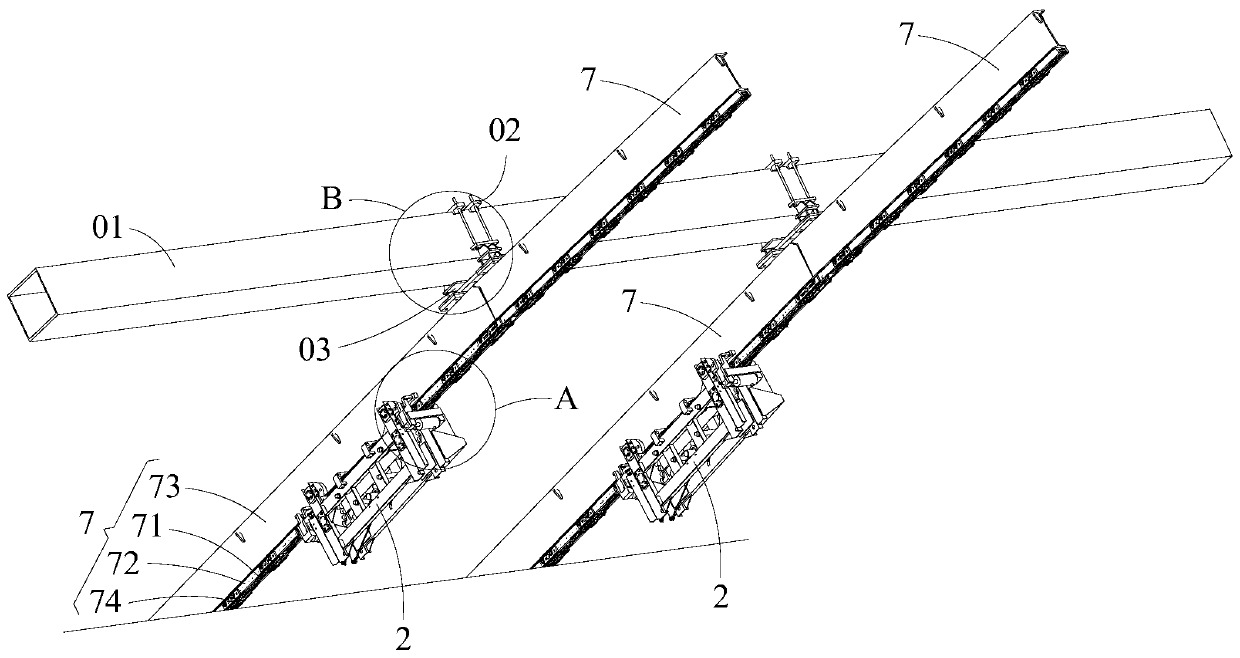

[0058] Such as Figure 1-6 Shown, the installation method of a kind of chain track of the present invention, uses a kind of chain track installation vehicle, and this installation vehicle comprises:

[0059] track laying base 1;

[0060] The running mechanism 2 is arranged on the track laying base 1, the running mechanism 2 is connected to the installed track segment 7, the track segment 7 is provided with a chain 71, and the running mechanism 2 is provided with Gear 21, the cooperation of described gear 21 and described chain 71 makes described walking mechanism 2 can move along described track segment 7, and the two ends of described track segment 7 are respectively provided with stretching mechanism 74, and described stretching The release mechanism 74 is used for tensioning, loosening, connecting and installing of the chain 71;

[0061] The driving mechanism 3 is arranged on the track laying base 1, and the driving mechanism 3 is used to drive the gear 21 to move along t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com