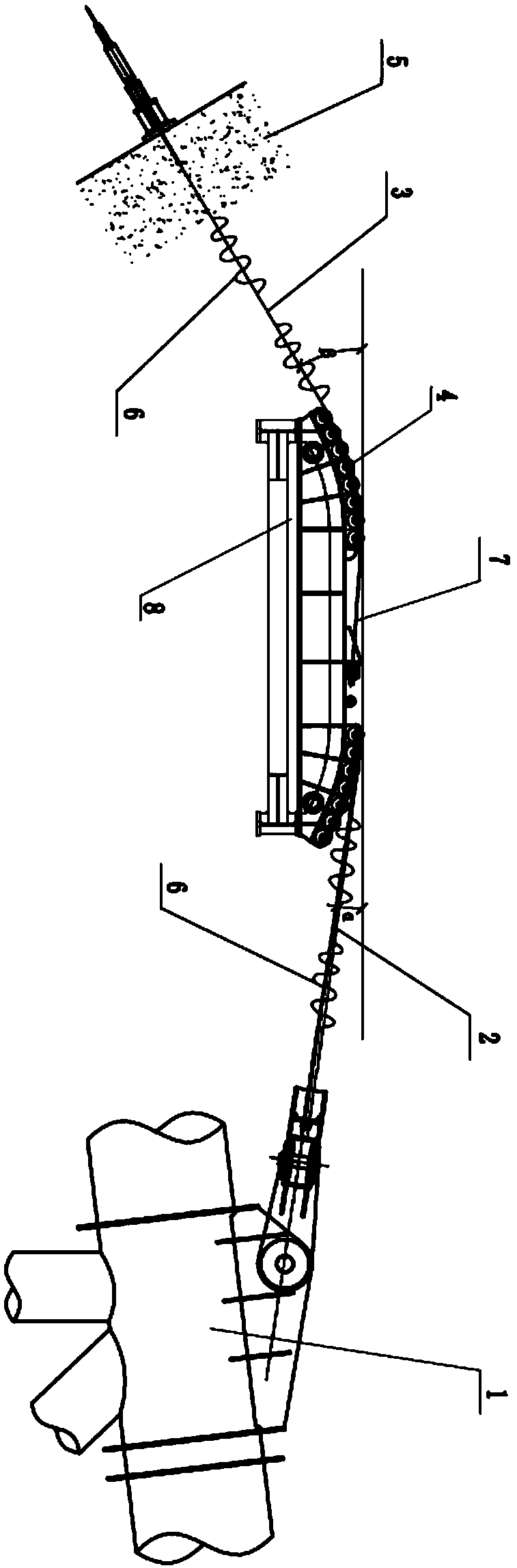

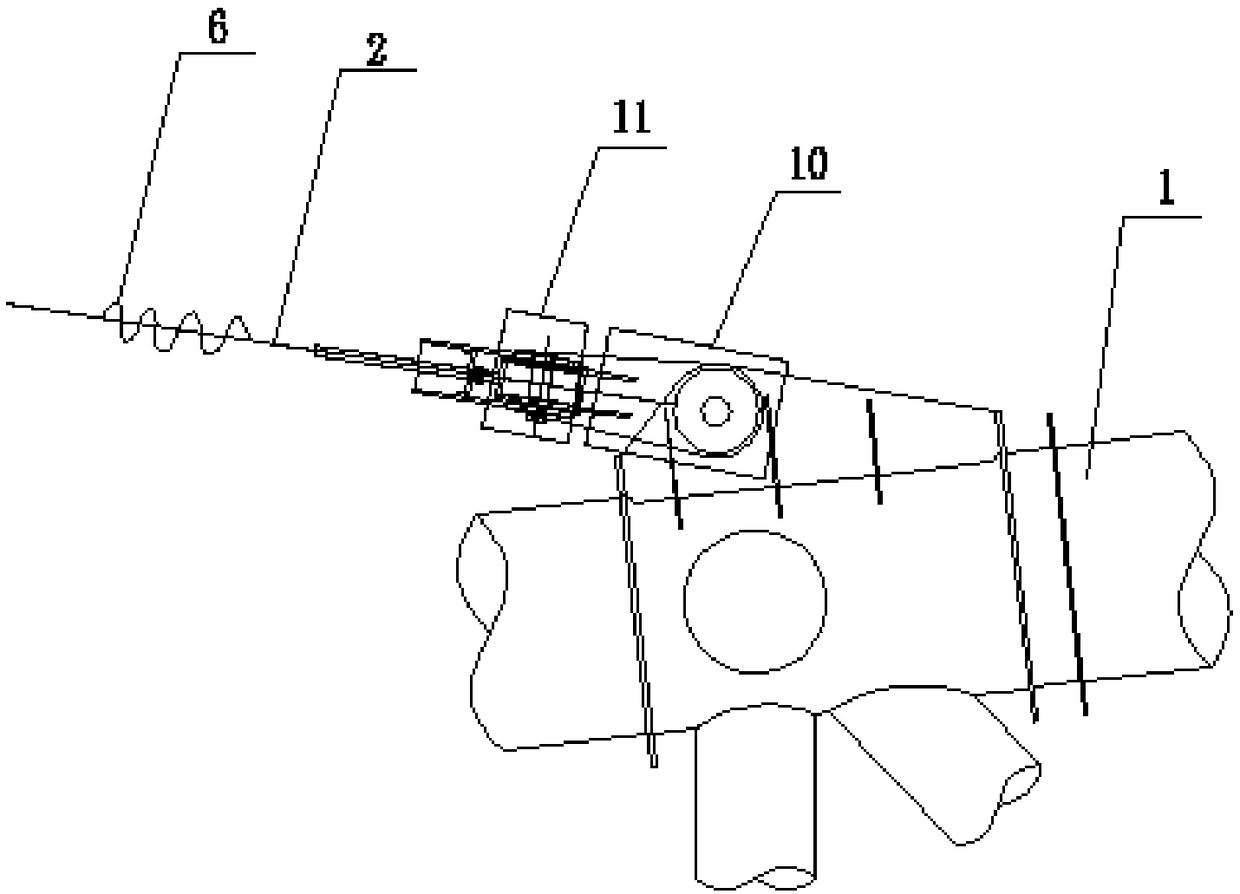

Cable-stayed buckling structure for bridge construction

A bridge construction and cable-stayed buckle technology, applied in bridges, bridge parts, bridge forms, etc., can solve problems such as shortening the service life of buckle cables, impact of buckle towers, safety accidents, etc., to ensure normal work and increase bending radius. , the effect of reducing the impact effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

experiment example

[0044] Option 1: adopt the horizontal straight line structure at both ends of the existing steering support platform (that is, the two ends of the steering support platform are non-arc surface structures), install the buckle saddle components on the two ends of the steering support platform correspondingly, and The bottom diameter of the pulley wheel groove 44 on the buckle cable saddle assembly is designed to be 450mm, and the steel strand wrapping angle is 30deg.

[0045] Scheme 2: The two ends of the steering support platform are arc-shaped surface structures (that is, the improved steering support platform structure of the invention), and the buckle saddle components are also installed on the two ends of the steering support platform correspondingly, and the buckle cable The bottom diameter of the pulley groove 44 on the saddle assembly is designed to be 120mm, and the steel strand wrapping angle is 5deg.

[0046] Get the steel strand buckles of the same specification to c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com