Alcohol ester type compound gasoline additive and preparation method thereof

A gasoline additive and alcohol ester type technology, which is applied in the field of gasoline additives, can solve the problems of poor stability of methanol gasoline, easy to generate air resistance, difficult to ignite, etc., and achieves good effects of removing impurities and decolorization, improving efficiency and good stability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

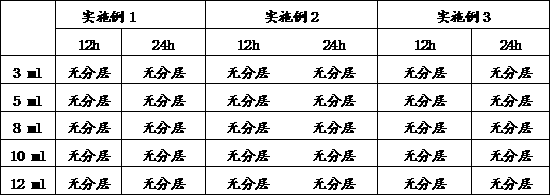

Examples

Embodiment 1

[0055] Alcohol ester type composite gasoline additive, described composite gasoline additive is processed from the following components by weight percentage:

[0056] Methanol 75%

[0057] Ethanol 15%

[0058] Ethyl acetate 5%

[0059] Star anise gold plate seed oil 10%;

[0060] The preparation side step of embodiment 1 alcohol ester type composite gasoline additive is as follows:

[0061] The first step is to prepare the star anise gold plate seed oil

[0062] S1: Break the star anise jinpan seed, add petroleum ether to the star anise jinpan seed powder and mix evenly according to the mass of the star anise jinpan seed powder g:petroleum ether ml is 1:10, the boiling range of the petroleum ether is 60°C;

[0063] S2: Place the suspension obtained in step S1 in an ultrasonic device for ultrasonic-assisted treatment for 1 hour at a temperature of 45°C and a power of 1000W;

[0064] S3: The suspension obtained in step S2 is subjected to decompression suction filtration to...

Embodiment 2

[0070] Alcohol ester type composite gasoline additive, described composite gasoline additive is processed from the following components by weight percentage:

[0071] Methanol 80%

[0072] Ethanol 5%

[0073] Ethyl acetate 10%

[0074] Star anise gold plate seed oil 5%;

[0075] The preparation method of embodiment 2 alcohol ester type compound gasoline additives, described preparation method step is as follows:

[0076] The first step is to prepare the star anise gold plate seed oil

[0077] S1: Break the star anise jinpan seed, add petroleum ether to the star anise jinpan seed powder according to the solid-liquid ratio of the quality of the star anise jinpan seed powder g:petroleum ether ml is 1:12, and mix evenly. The boiling range of the petroleum ether is 90°C;

[0078] S2: Place the suspension obtained in step S1 in an ultrasonic device for ultrasonic-assisted treatment for 5 hours at a temperature of 35°C and a power of 100W;

[0079] S3: The suspension obtained i...

Embodiment 3

[0085] Alcohol ester type composite gasoline additive, described composite gasoline additive is processed from the following components by weight percentage:

[0086] Methanol 75%

[0087] Ethanol 10%

[0088] Ethyl acetate 7.5%

[0089] Star anise gold plate seed oil 7.5%.

[0090] The preparation method of the alcohol ester type composite gasoline additive of embodiment 3, described preparation method step is as follows: the first step, prepare star anise gold plate seed oil

[0091] S1: Break the star anise jinpan seed, add petroleum ether to the star anise jinpan seed powder and mix evenly according to the mass of the star anise jinpan seed powder g:petroleum ether ml is 1:10, the boiling range of the petroleum ether is 80°C;

[0092] S2: Place the suspension obtained in step S1 in an ultrasonic device for ultrasonic-assisted treatment for 3 hours, at a temperature of 40°C, and with a power of 500W;

[0093] S3: The suspension obtained in step S2 is subjected to decom...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com