A treatment system and method for high boilers produced in a cold hydrogenation system

A treatment method and technology of high boiling substances, applied in the field of polysilicon preparation, can solve the problems of waste of chlorine and Si elements, unfavorable sustainable development of polysilicon production, environmental pollution, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

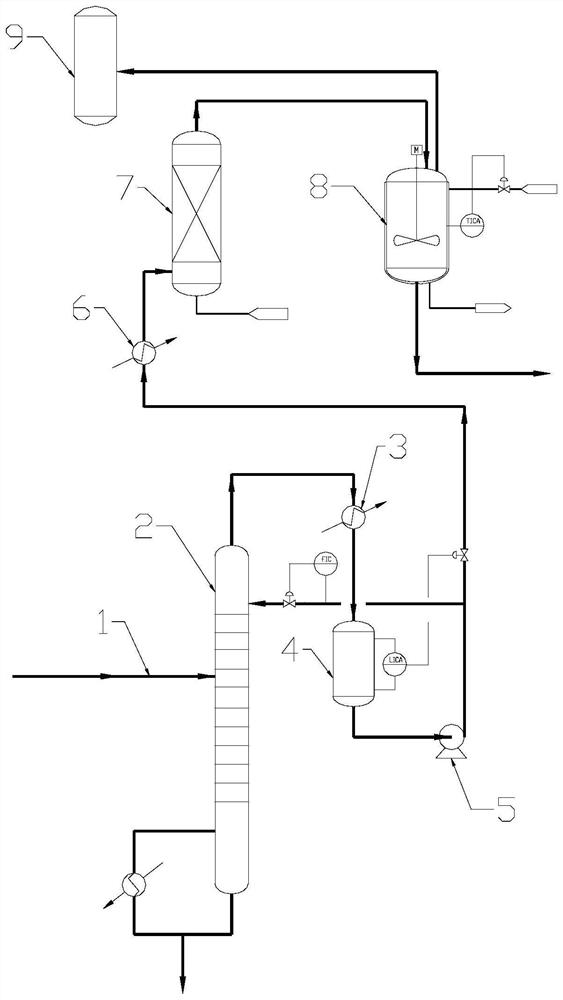

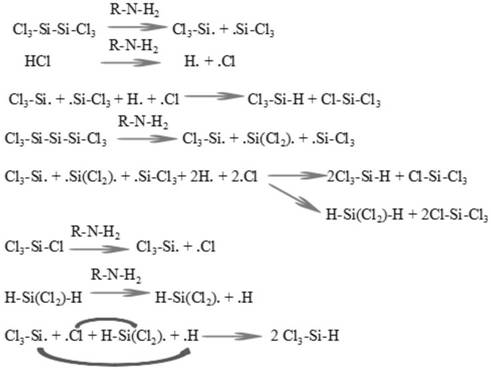

Method used

Image

Examples

Embodiment 1

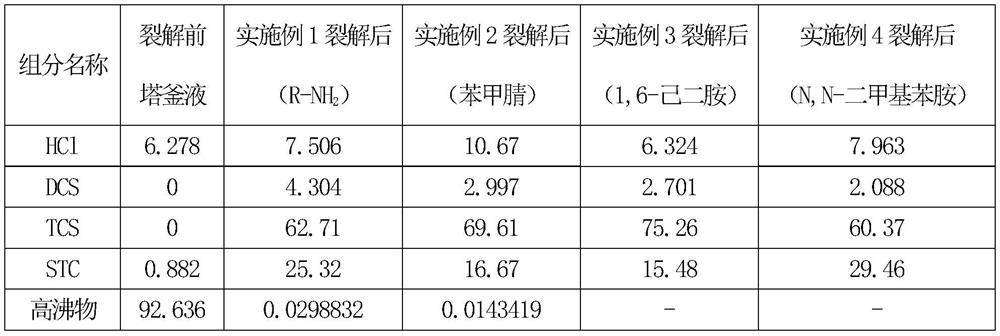

[0029] The high boilers are removed from the heavy metal impurities by the weight removal tower, and then heated to 90°C by the preheater and enter the polychlorosilane cracker. The catalyst basic quaternary ammonium macroporous cross-linked resin (solid state) is laid in the polychlorosilane cracker. Cracking gas (hydrogen chloride) is introduced into the polychlorosilane cracker. The reaction temperature in the polychlorosilane cracker is 90°C and the pressure is 0.2MPa. The silane is heated and evaporated into a gas in the evaporating tank, and then separated by a separation tower to obtain silicon tetrachloride and trichlorosilane. The amount of chlorosilane obtained by the cracking reaction was tested by gas chromatography, see Table 1 below for details.

Embodiment 2

[0031] The high boilers are removed from the heavy metal impurities by the weight removal tower, and then heated to 90°C by the preheater and enter the polychlorosilane cracker. The polychlorosilane cracker is equipped with catalyst benzonitrile (liquid), and the polychlorosilane cracker is fed into Cracked gas (hydrogen gas), the reaction temperature in the polychlorosilane cracker is 90°C, the pressure is 0.2MPa, the high boiler reacts with the cracked gas to obtain a chlorosilane mixture, and the chlorosilane mixture is then input into the chlorosilane evaporation tank to be heated and evaporated into a gas And then separated by separation tower to get silicon tetrachloride and trichlorosilane. The amount of chlorosilane obtained by the cracking reaction was tested by gas chromatography, see Table 1 below for details.

Embodiment 3

[0033] The high boilers are removed from the heavy metal impurities by the weight removal tower, and then heated to 90°C by the preheater and enter the polychlorosilane cracker. The polychlorosilane cracker is equipped with a catalyst 1,6-hexamethylenediamine (liquid state), and the polychlorosilane cracks The pyrolysis gas (chlorine gas) is introduced into the polychlorosilane cracker, the reaction temperature in the polychlorosilane cracker is 90°C, the pressure is 0.2MPa, the high boiler reacts with the cracked gas to obtain a chlorosilane mixture, and the chlorosilane mixture is then input into the chlorosilane evaporation tank After heating and evaporating into a gas, it can be separated by a separation tower to obtain silicon tetrachloride and trichlorosilane. The amount of chlorosilane obtained by the cracking reaction was tested by gas chromatography, see Table 1 below for details.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com