A shell breaking mold specially used for walnut shell breaking

A technology for breaking shells and walnuts, applied in the directions of shelling, application, pod removal, etc., can solve the problems of incomplete shell breaking, reduced walnut integrity, and difficulty in taking into account the shape and size of walnuts, so as to ensure shell breaking efficiency and improve shell breaking. Efficiency and Integrity Guarantee

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

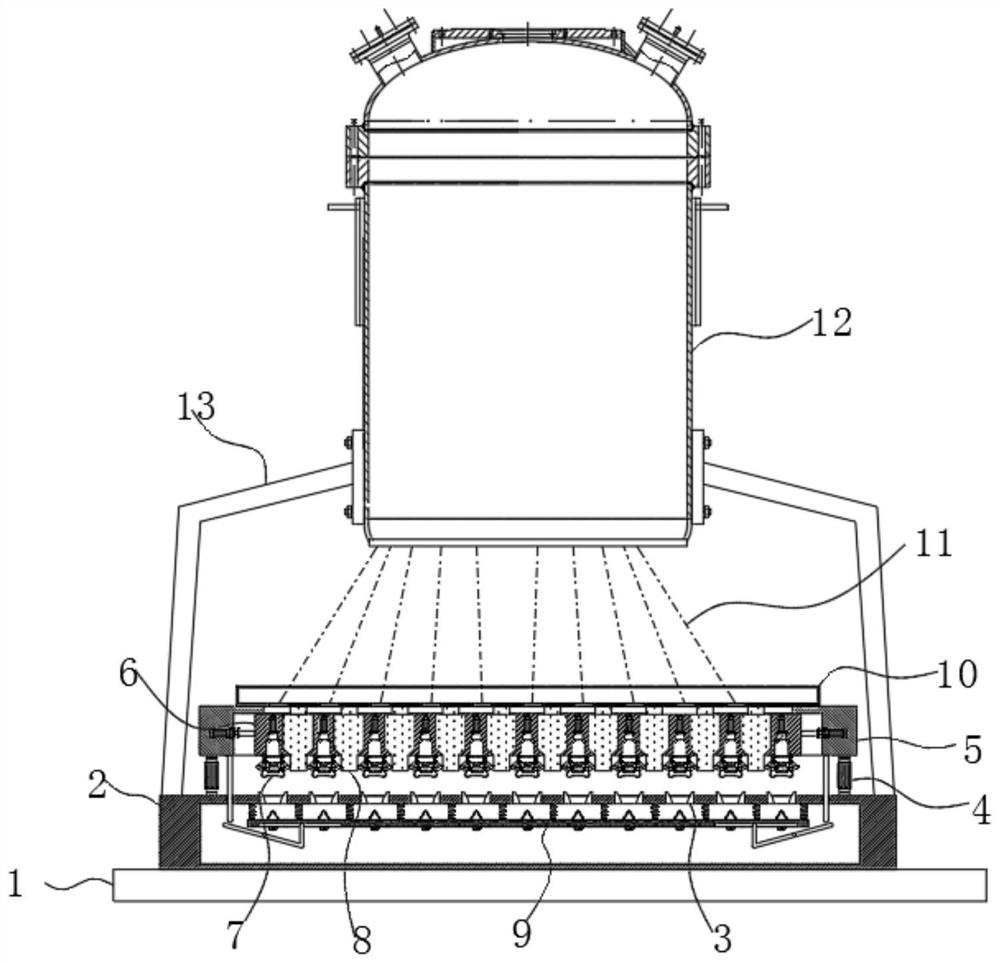

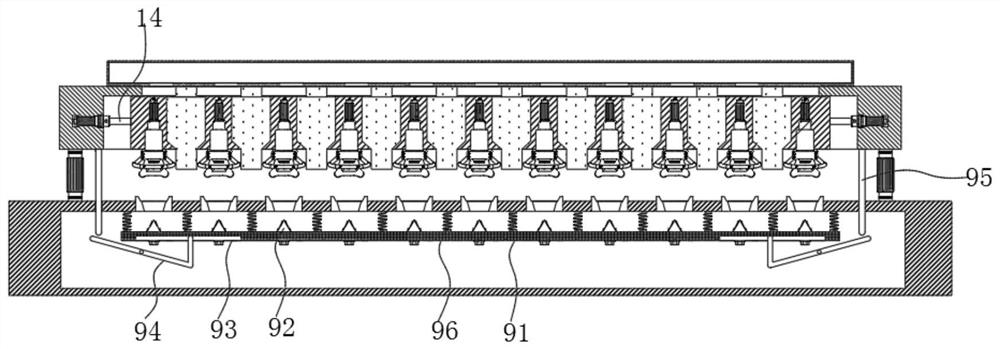

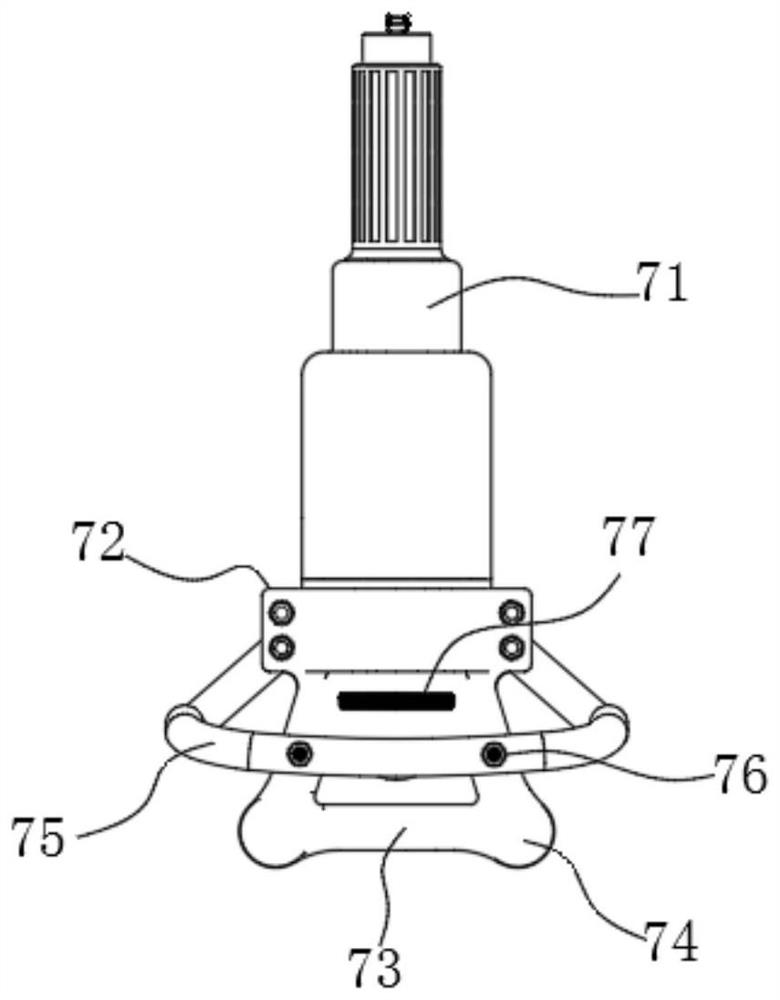

[0023] see Figure 1~4 , in the embodiment of the present invention, a walnut shell cracking die is characterized in that it includes a base 1, a lower mold base 2, a die 3, a vertical expander 4, a mounting base 5, an upper mold base 6 and The punch assembly 7, wherein the lower mold base 2 is fixed on the base 1, the lower mold base 2 is a base with a cavity, and its upper surface is evenly provided with a plurality of holes communicating with the cavity. through holes, and a die 3 is fixedly embedded in the through holes, and a punch assembly 7 is correspondingly arranged in the space above each of the die 3, and the punch assembly 7 is arranged in an upper die holder 6, and The upper mold base 6 is arranged in the mounting base 5, and the mounting base 5 is connected to the lower mold base 2 by at least two vertical expanders 4, and the punch is completed through the expansion and contraction of the vertical expanders 4. The relative movement of assembly 7 and die 3 reali...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com