Mechanical and electrical equipment for grinding edge of glass

A technology for electromechanical equipment and glass edging, applied in grinding/polishing equipment, machine tools suitable for grinding the edge of workpieces, metal processing equipment, etc., can solve problems such as poor water circulation of water pumps, no filtering device, sluggish water pump damage, etc. , to achieve good practical benefits, ensure normal use, and ensure the quality of polishing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

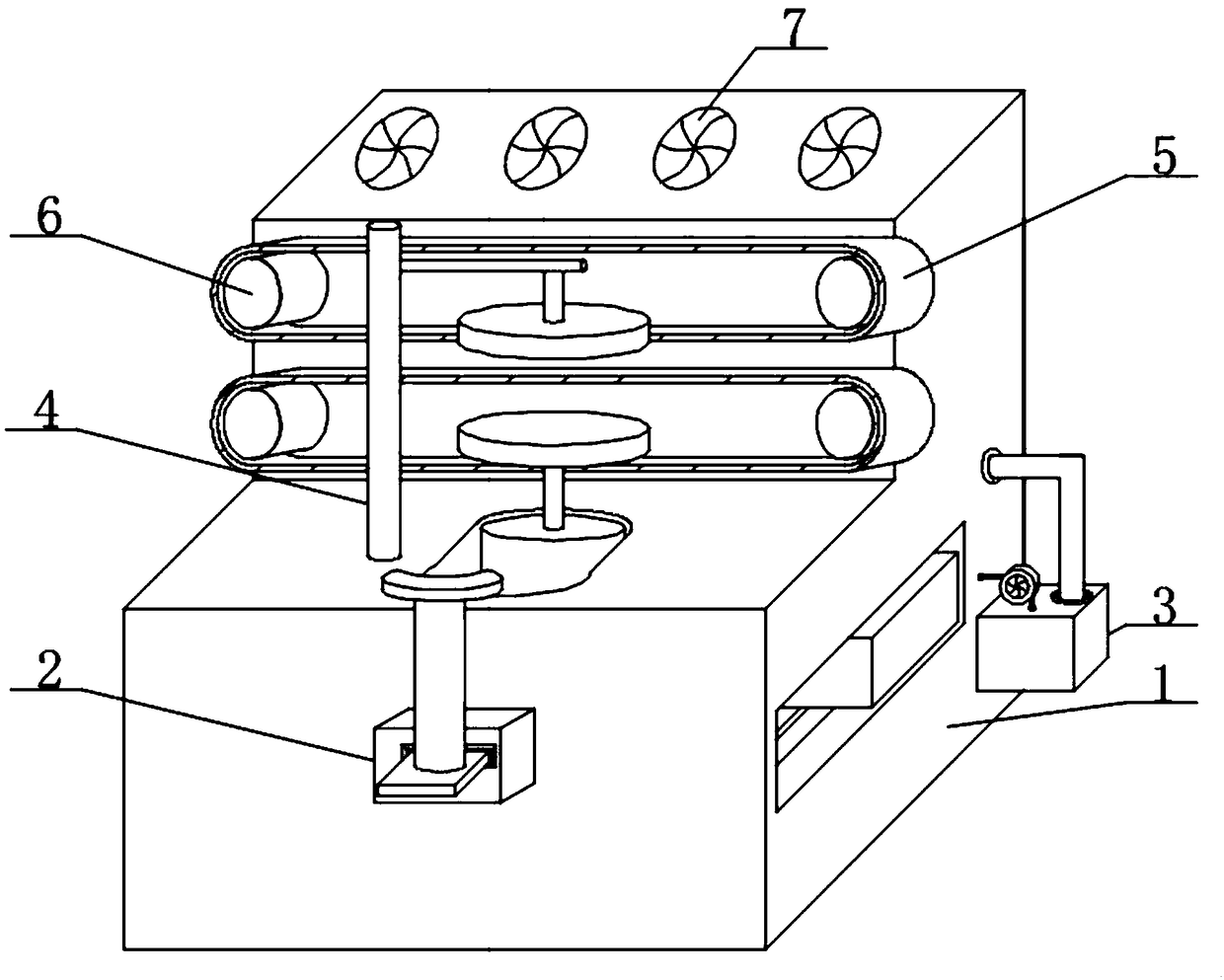

[0029] see figure 1 , Figure 6 , Figure 7 and Figure 8 , the present invention provides a technical solution:

[0030] An electromechanical device for glass edging, including a housing 1, a limiting device 2, a filtering device 3 and a fixing device 4, the right end of the housing 1 is fixedly connected with a filtering device 3, and the filtering device 3 includes a water tank 301, a water pipe 302, and a water pump 303 and water delivery pipe 304, the left end of the water tank 301 is fixedly connected to the housing 1, the top surface of the water tank 301 is fixedly connected to the water pump 303, the output end and the input end of the water pump 303 are connected to the water pipe 302, and the lower side water pipe 302 is connected to the water tank 301 The other end of the upper side water pipe 302 is fixedly connected with a nozzle 309, the upper end surface of the water tank 301 is spirally connected with a filter cartridge 305 on the right side, and the upper ...

Embodiment 2

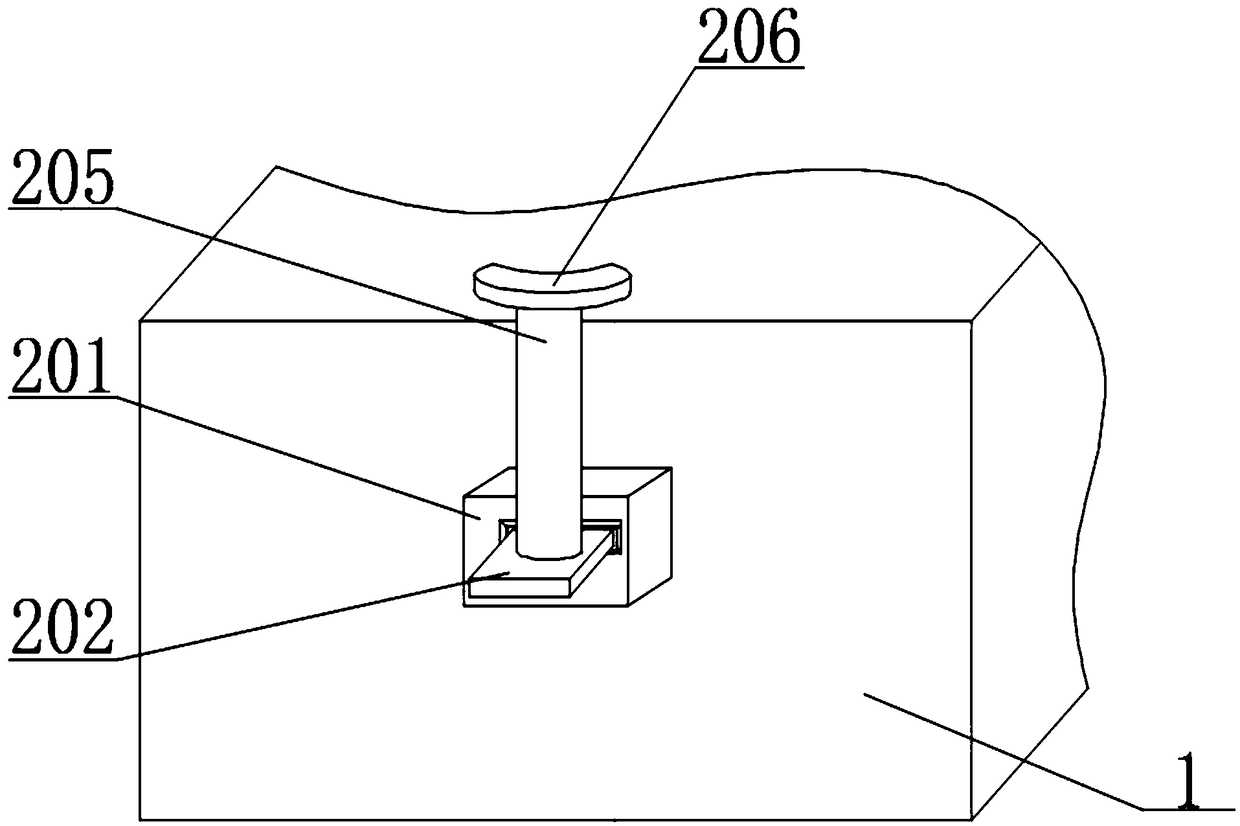

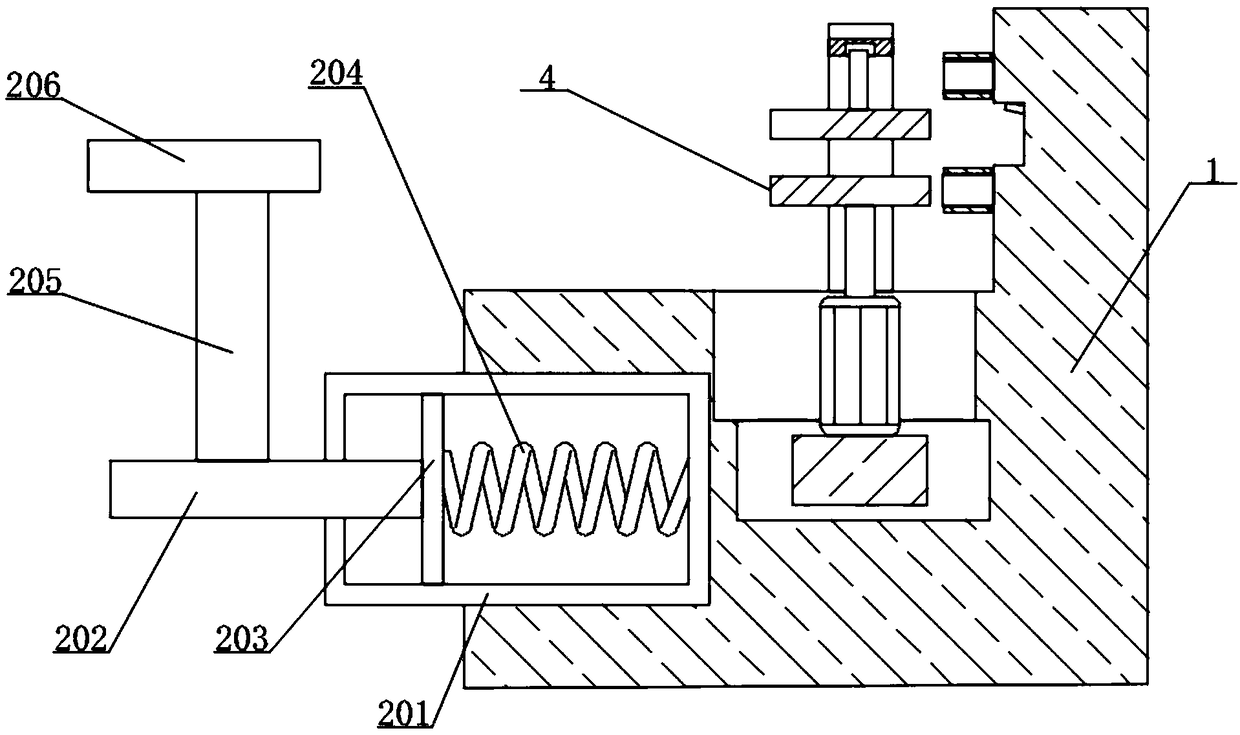

[0034] see figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Figure 6 , Figure 7 , Figure 8 and Figure 9 , the present invention provides a technical solution:

[0035] An electromechanical device for glass edging, including a housing 1, a limiting device 2, a filtering device 3 and a fixing device 4, the right end of the housing 1 is fixedly connected with a filtering device 3, and the filtering device 3 includes a water tank 301, a water pipe 302, and a water pump 303 and water delivery pipe 304, the left end of the water tank 301 is fixedly connected to the housing 1, the top surface of the water tank 301 is fixedly connected to the water pump 303, the output end and the input end of the water pump 303 are connected to the water pipe 302, and the lower side water pipe 302 is connected to the water tank 301 The other end of the upper side water pipe 302 is fixedly connected with a nozzle 309, the upper end surface of the water tank 301 is spirally connected...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com