Welding nut automatic welding device

A technology for welding nuts and automatic welding, applied in auxiliary devices, welding equipment, welding equipment, etc., can solve the problems of poor work efficiency, high labor intensity, long time required, etc., improve dimensional accuracy and stability, and ensure welding The effect of quality and efficiency improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0042] The fast positioning of the workpiece 81 is realized by the workpiece positioning device, the nut vibration conveying device 11 and the nut conveying rod 12 realize the automatic conveying of the welding nut 82, and the nut positioning device realizes the rapid positioning of the welding nut 82, which greatly improves the efficiency.

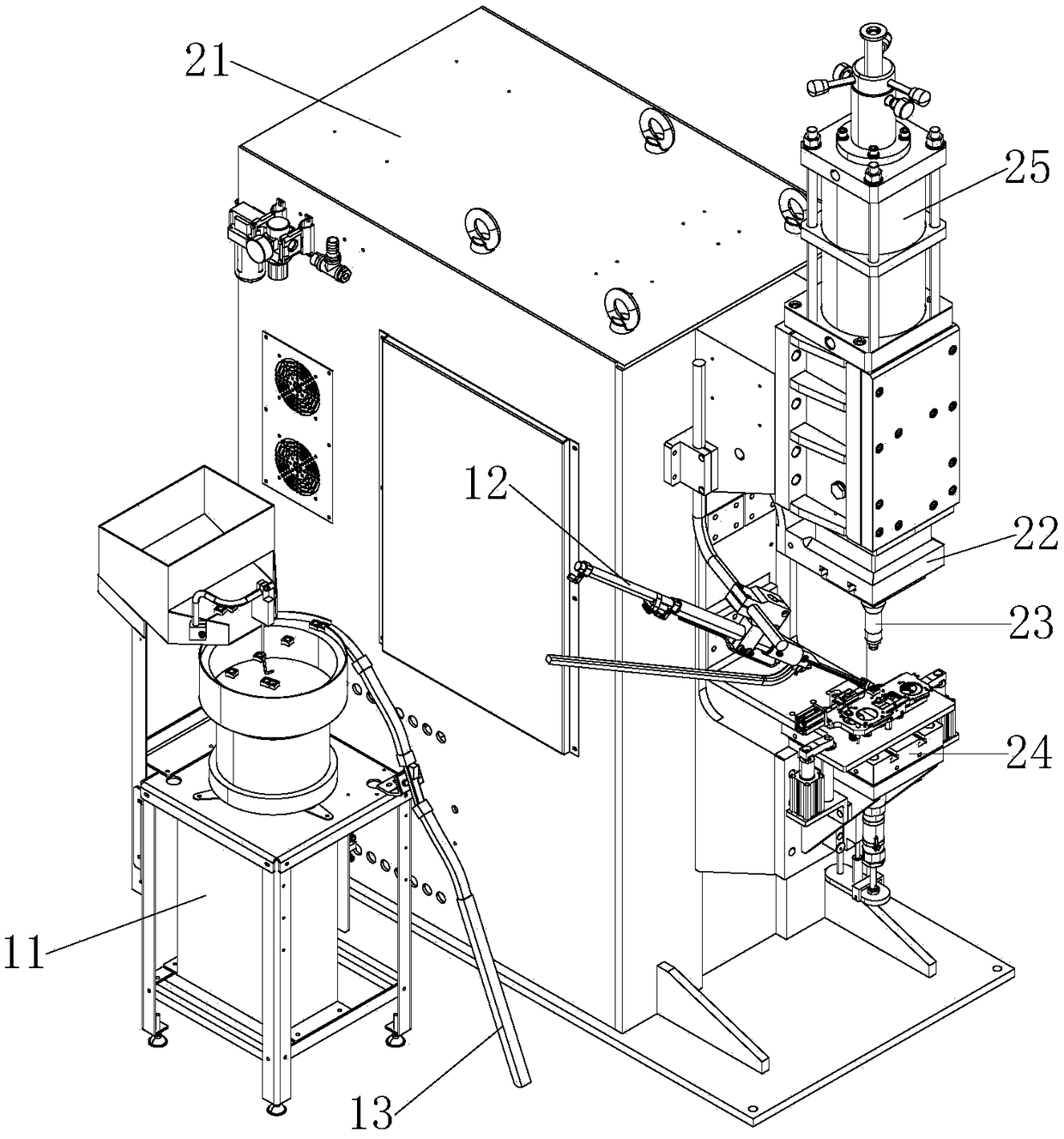

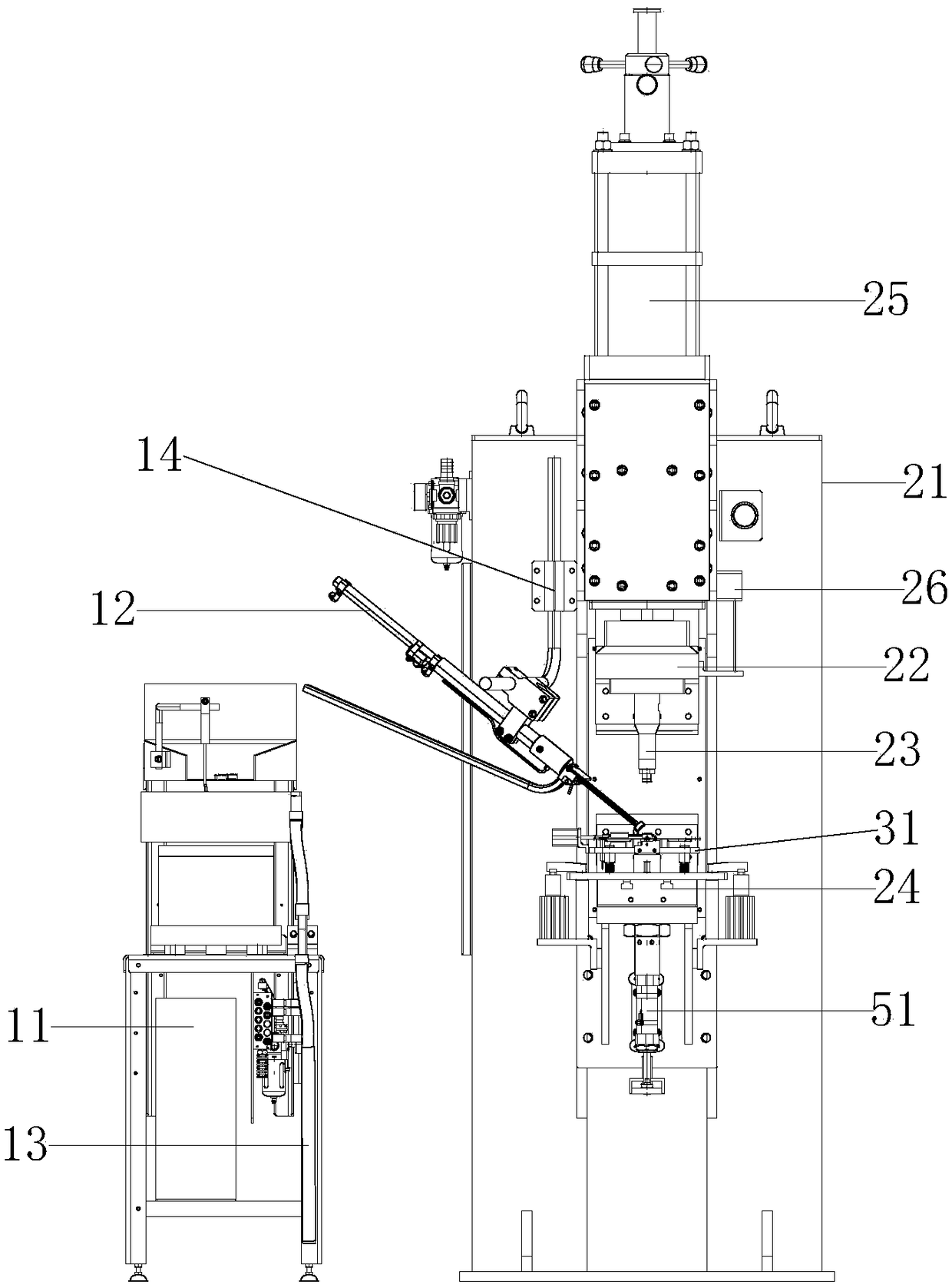

[0043] like Figure 1 to Figure 5 As shown, the welding nut automatic welding device includes a nut vibration conveying device 11 and a nut conveying rod 12, and the nut vibrating conveying device 11 is connected with the nut conveying rod 12 through a hose 13; it also includes a workpiece positioning device and a nut positioning device; the workpiece positioning device and the nut positioning device are all installed on the welding seat 24; the workpiece positioning device is used to place the workpiece 81; the lower electrode 42 is installed on the nut positioning device, and the lower electrode 42 is located at the bottom of the workpie...

Embodiment 2

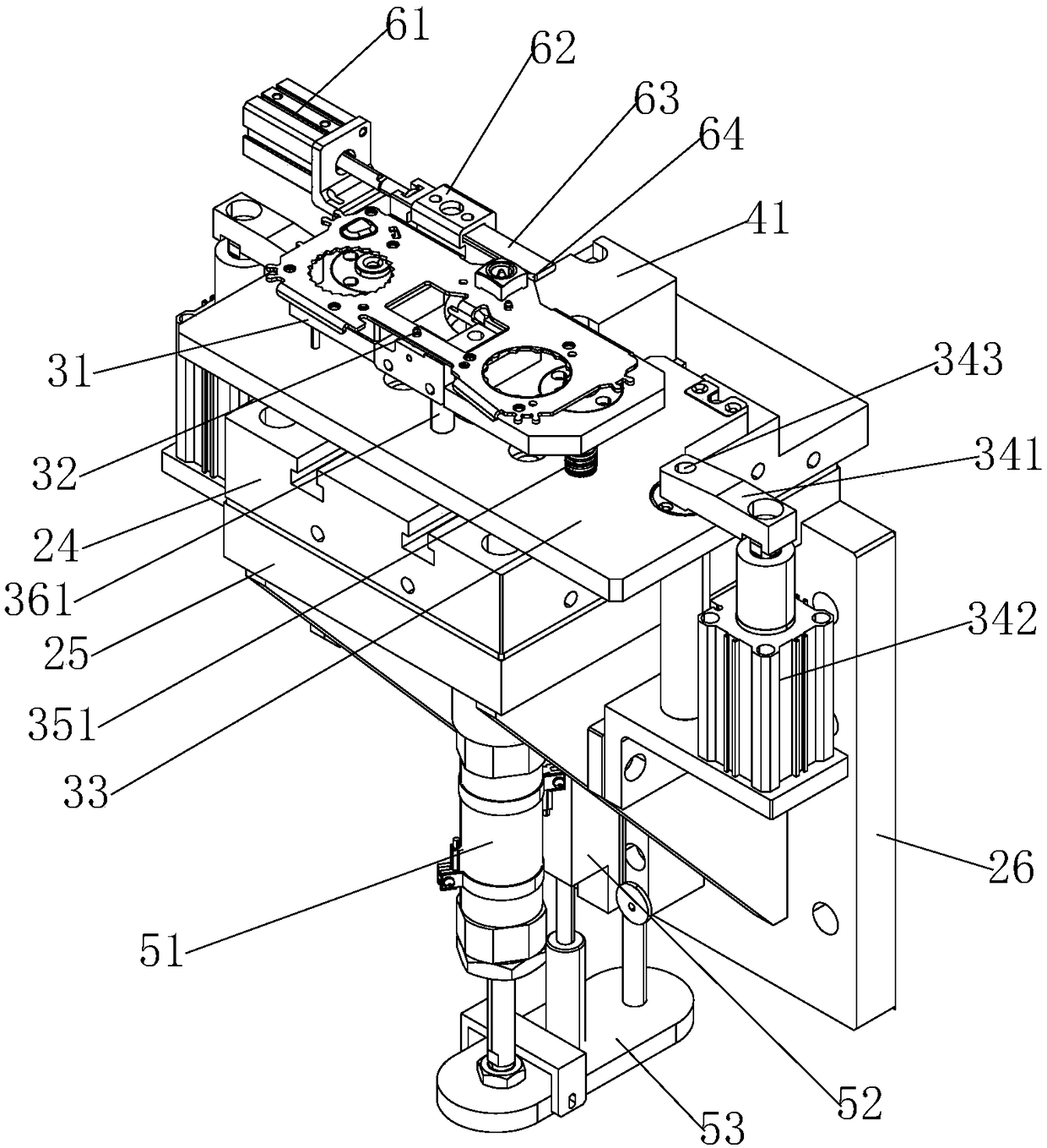

[0051] On the basis of the first embodiment above, as Figure 3 to Figure 5 Shown, also comprise base plate 33, elevating rod 352, return spring 351, adjusting screw 362 and adjusting post 361; Base plate 33 is installed on the welding seat 24; The lifting hole, the lifting hole is slidably inserted on the lifting rod 352; the adjusting column 361 is fixed on the base plate 33, and the adjusting column 361 is provided with a threaded hole; Connection; the return spring 351 is located between the positioning plate 31 and the bottom plate 33 , and is sleeved on the lifting rod 352 .

[0052] The positioning plate 31 can be lifted up and down, and the return spring 351 keeps the positioning plate 31 at a high place. The adjustment screw 362 adjusts the height of the positioning plate 31 .

[0053] Since the top surface of the lower electrode 42 is worn after being used for a period of time, scratches, pits, etc. will affect the welding, and it needs to be ground and leveled bef...

Embodiment 3

[0056] On the basis of the above-mentioned embodiment one or two, as Figure 3 to Figure 5 As shown, the nut positioning device also includes a sliding seat 41 and a lifting cylinder 51; the sliding seat 41 is fixed on the welding seat 24, the lower electrode 42 is fixed on the top of the sliding seat 41, and the center of the sliding seat 41 is provided with a sliding hole 411, and the sliding hole 411 is arranged on the same axis as the pin hole; the nut positioning pin 55 is slidably inserted in the sliding hole 411, the nut positioning pin 55 is connected with the piston rod of the lifting cylinder 51, and the lifting cylinder 51 is fixed on the welding seat 24, and the piston rod of the lifting cylinder 51 Connect with the nut positioning pin 55.

[0057] The lower electrode 42 is fixed on the electrode seat 43 , and the electrode seat 43 is installed on the sliding seat 41 . The electrode holder 43 facilitates the disassembly and assembly of the lower electrode 42 .

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com