Automatic sorting device based on image recognition

An image recognition and automatic sorting technology, applied in sorting and other directions, can solve problems such as low correct rate, disordered sorting, and focus on sorting efficiency, achieving high efficiency and high correct rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

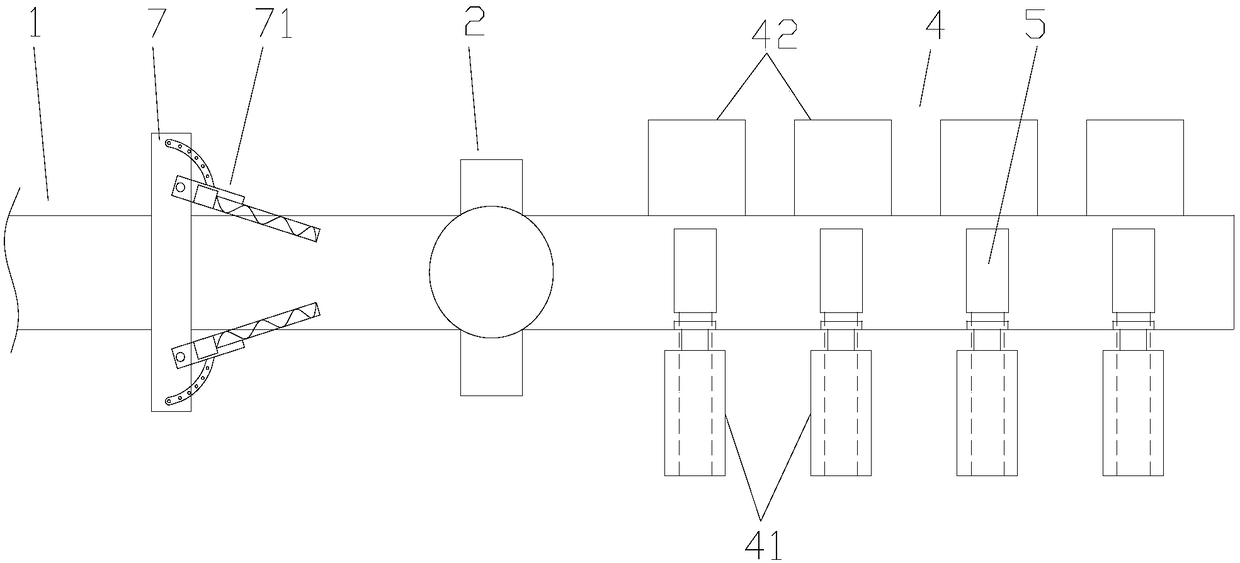

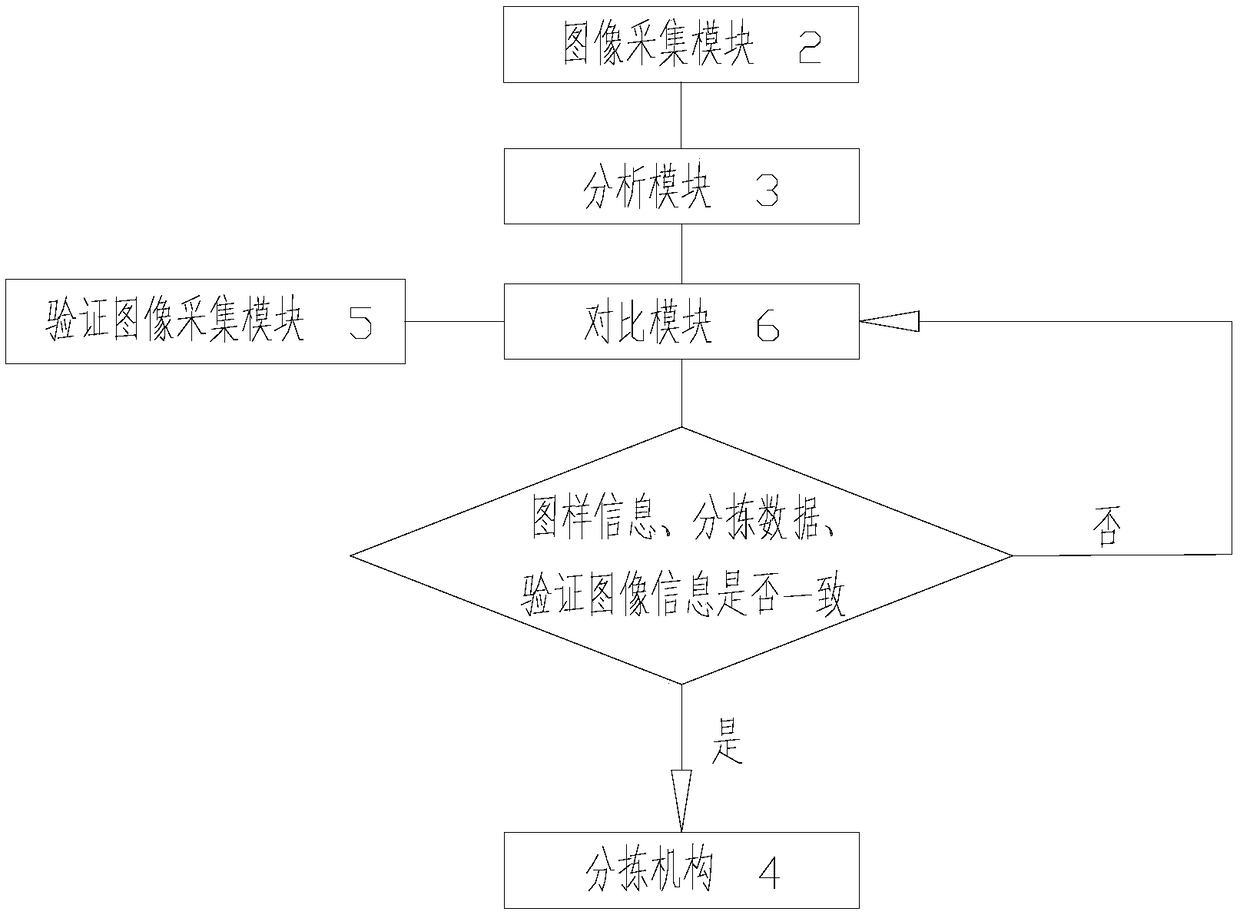

[0029] Embodiment 1: refer to figure 1 , figure 2 ,, an automatic sorting device based on image recognition, including a conveyor line 1, a material sorting mechanism, an image recognition unit, and a sorting unit arranged on the conveyor line 1 in sequence, and the conveyor line 1 is composed of a conveyor frame, a conveyor belt on the conveyor frame, Consisting of driving elements that drive the conveyor belt to rotate, the image recognition unit includes an image acquisition module 2 that collects pattern information of all items on the conveyor line 1, and an analysis module 3 that generates sorting data corresponding to the items based on the pattern information collected by the image acquisition module 2.

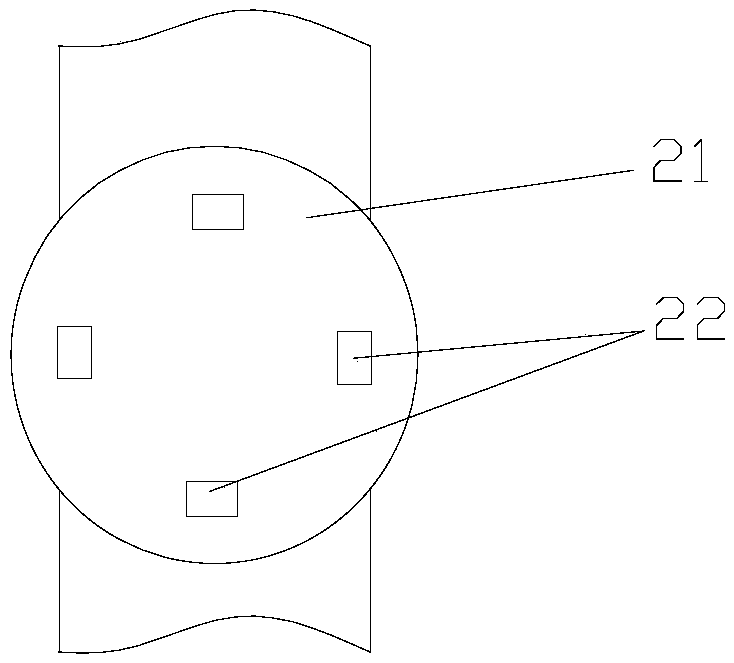

[0030] refer to image 3 , Figure 4 , the image acquisition module 2 comprises the acquisition support 21 erected on the conveyor line 1, the image acquisition camera 22 facing the conveyor belt set on the acquisition support 21, the number of the image acquisitio...

Embodiment 2

[0033] Embodiment 2: refer to figure 1 , figure 2 , an automatic sorting device based on image recognition, including a conveyor line 1, a material sorting mechanism, an image recognition unit, and a sorting unit arranged on the conveyor line 1 in sequence, and the conveyor line 1 is driven by a conveyor frame, a conveyor belt on the conveyor frame, and Conveyor belt rotating drive components, the image recognition unit includes an image acquisition module 2 that collects the pattern information of all items on the conveyor line 1, and an analysis module 3 that generates the corresponding sorting data for the items based on the pattern information collected by the image acquisition module 2. Refer to Figure 7 , Figure 8 , the image acquisition module 2 includes an acquisition support 21 erected on the conveying line 1, an image acquisition camera 22 facing the conveyor belt set on the acquisition support 21, and the number of image acquisition cameras 22 is 5, of which fou...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com