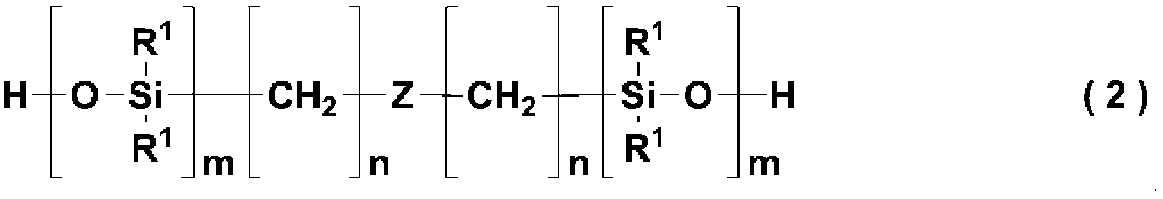

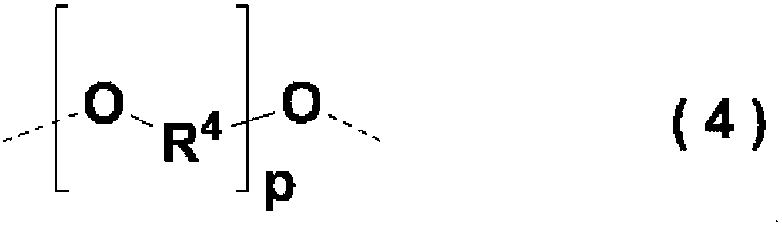

Silanol-group-terminated polyoxyalkylene compound and production process therefor, room-temperature-curable composition, sealing material, and article

A technology of polyoxyalkylene and manufacturing method, which is applied in the direction of chemical instruments and methods, polyether adhesives, adhesive types, etc., and can solve problems such as insufficient curing and development limitations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0218] In a 500 mL four-neck detachable flask equipped with a stirrer, a reflux condenser, a thermometer, and a dropping funnel, 500 g of polypropylene glycol containing a terminal allyl group having a molecular weight of 7400 (0.160 moles in terms of the functional group of the terminal allyl group) ), a platinum catalyst (vinylsiloxane complex solution of chloroplatinic acid, platinum concentration: 1% by mass) 1.0 g, and the temperature was raised to 90° C. while heating and stirring.

[0219] Next, with stirring, 1-hydroxy-octamethyltetrasiloxane (i.e., 1-hydroxy-7-hydrogen-1,1,3,3,5,5,7,7-octamethyl Tetrasiloxane) 50 g (0.167 mol of terminal Si—H functional groups), heat generation was confirmed, the reaction temperature was 90 to 95° C., and the reaction system was maintained for 6 hours. After the reaction, a small amount of excess 1-hydroxy-octamethyltetrasiloxane was removed under reduced pressure. After cooling to room temperature, it was filtered to obtain 520 g of...

Embodiment 2

[0224] In a 500-mL four-necked detachable flask equipped with a stirrer, a reflux condenser, a thermometer, and a dropping funnel, 500 g of polypropylene glycol containing terminal allyl groups having a molecular weight of 8400 (0.112 moles in terms of functional groups of terminal allyl groups) ), a platinum catalyst (vinylsiloxane complex solution of chloroplatinic acid, platinum concentration: 1% by mass) 1.0 g, and the temperature was raised to 90° C. while heating and stirring.

[0225] Next, under stirring, 35 g of 1-hydroxy-octamethyltetrasiloxane (0.117 moles of terminal Si-H functional groups) was added dropwise, heat generation was confirmed, and the reaction temperature became 90 to 95° C., and the reaction system was kept 6 hours. After the reaction, a small amount of excess 1-hydroxy-octamethyltetrasiloxane was removed under reduced pressure. After cooling to room temperature, it was filtered to obtain 505 g of polypropylene glycol (polymer B) having a terminal s...

Embodiment 3

[0227] In a 500 mL four-neck detachable flask equipped with a stirrer, a reflux condenser, a thermometer, and a dropping funnel, 250 g of polypropylene glycol containing a terminal allyl group having a molecular weight of 4300 (0.107 moles in terms of a terminal allyl group) ), a platinum catalyst (vinylsiloxane complex solution of chloroplatinic acid, platinum concentration: 1% by mass) 1.0 g, and the temperature was raised to 90° C. while heating and stirring.

[0228] Next, under stirring, 33 g of 1-hydroxy-octamethyltetrasiloxane (0.110 mol of terminal Si-H functional groups) was added dropwise, heat generation was confirmed, and the reaction temperature became 90 to 95° C., and the reaction system was kept 6 hours. After the reaction, a small amount of excess 1-hydroxy-octamethyltetrasiloxane was removed under reduced pressure. After cooling to room temperature, it was filtered to obtain 268 g of polypropylene glycol (polymer C) having a terminal silanol group (viscosity...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com