Method for preparing chlorinated polyvinyl chloride resin

A chlorinated polyvinyl chloride and resin technology, applied in the field of preparation of chlorinated polyvinyl chloride resin, can solve problems such as inability to effectively remove HCl, CPVC white index deterioration, etc., achieve excellent thermal stability, excellent white index, and reduce costs Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

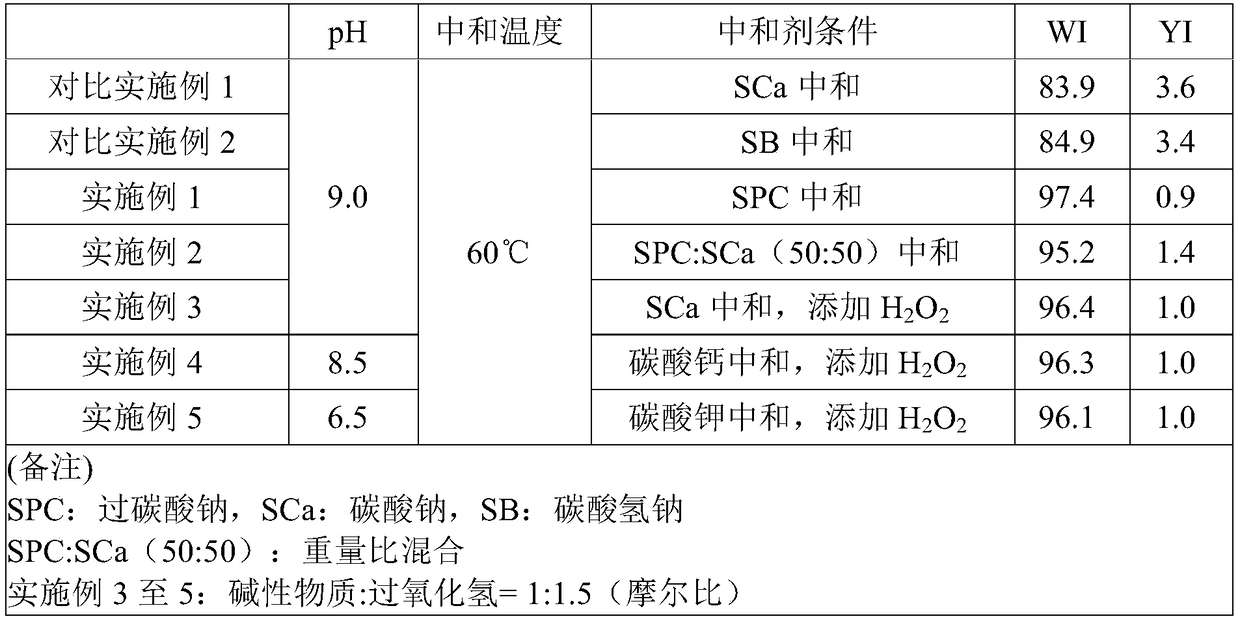

Examples

preparation example Construction

[0041] Preparation steps of CPVC

[0042] Although the step of synthesizing CPVC can be carried out according to a conventional known method, and the configuration is not particularly limited, it can preferably be carried out as follows.

[0043] For example, the chlorination reaction can be carried out by introducing PVC or a PVC-containing copolymer into a reactor, then removing oxygen under vacuum, introducing hydrochloric acid, and then carrying out a photoreaction by UV irradiation while raising the temperature .

[0044] The PVC or PVC-containing copolymer used in the chlorination reaction can be used in the state of a slurry containing a solvent. The slurry may contain water used in the polymerization, and the ratio of PVC to water may be 10 to 35% by weight. Here, the kind of the solvent to be introduced is not particularly limited, and water can be used.

[0045] The PVC or PVC-containing copolymer can be prepared by copolymerization of vinyl chloride monomer alo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com