Method for dividing and processing sheet-like material in a machine and corresponding machine

A technology for processing boards, machines, applied in the field of machines that perform the method, capable of solving the problems of reducing the dynamics of the movement of the processing head, reducing machine efficiency, contour errors, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

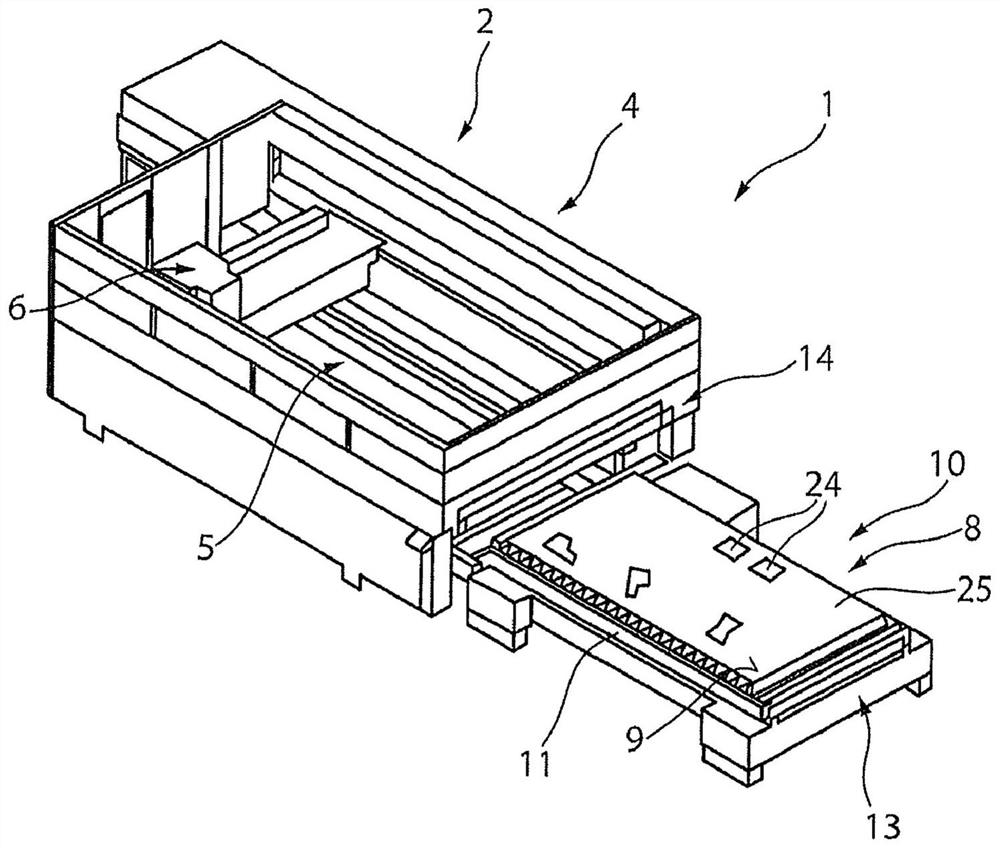

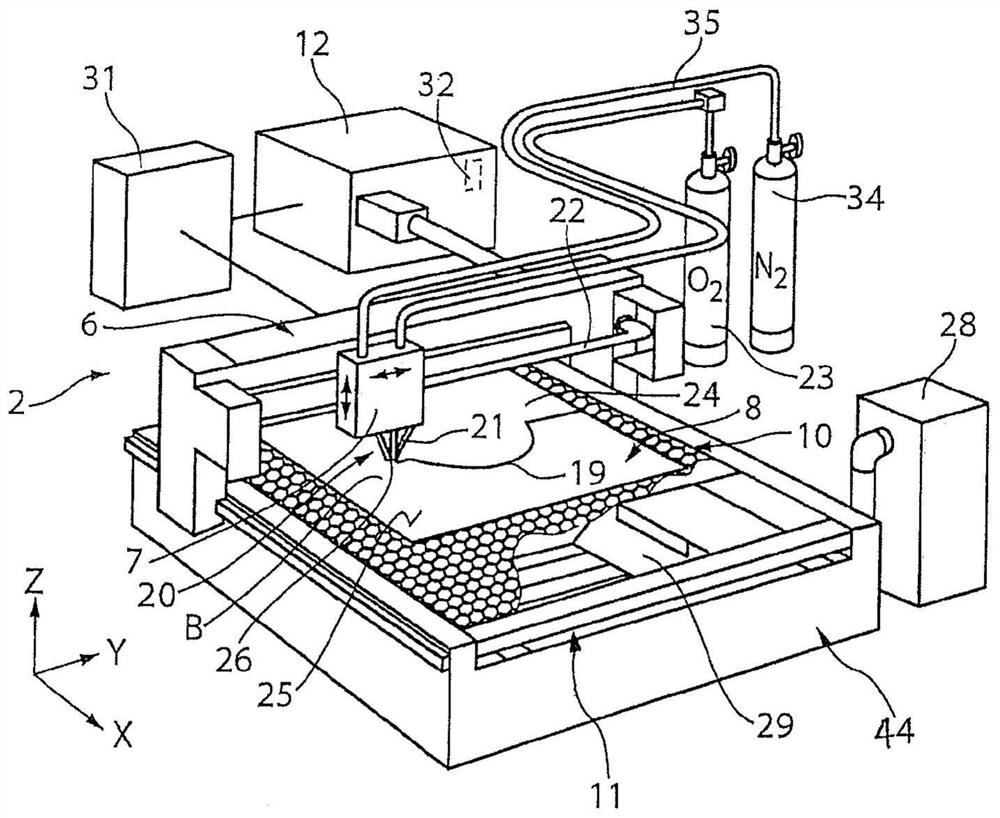

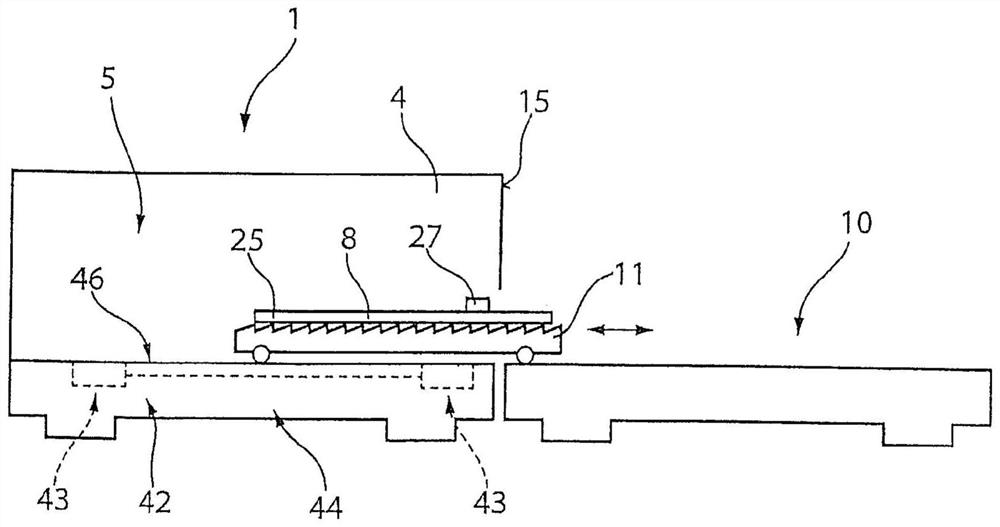

[0032] in figure 1 The middle three-dimensionally shows a facility 1 for dividing and processing a plate-like material 8 made of metal, for example. This facility 1 includes machine 2, which will also be figure 2 Discussed in detail. The machine 2 is surrounded by a housing 4. The housing 4 is provided with a processing station 5 in which a processing unit 6 having at least one processing head 7 can move in a horizontal movement plane. A loading and unloading station 10 is provided outside the housing 4. The loading and unloading station includes at least one movable pallet 11 on which a plate-like material 8 is supported for processing. Preferably, the loading and unloading station 10 is constituted by a so-called pallet changer 13, on which the pallet 11 is supported. Supplementally and not shown in detail, the loading and unloading station 10 is equipped with an operating device through which the unprocessed plate material 8 is used as a blank before the pallet 11 is mov...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com